Chemical and mechanical grinding method

A grinding method and chemical-mechanical technology, used in surface polishing machine tools, grinding/polishing equipment, electrical components, etc., can solve the problems of corrosion and easy contamination of wafer surface materials, and achieve the effect of corrosion inhibition and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

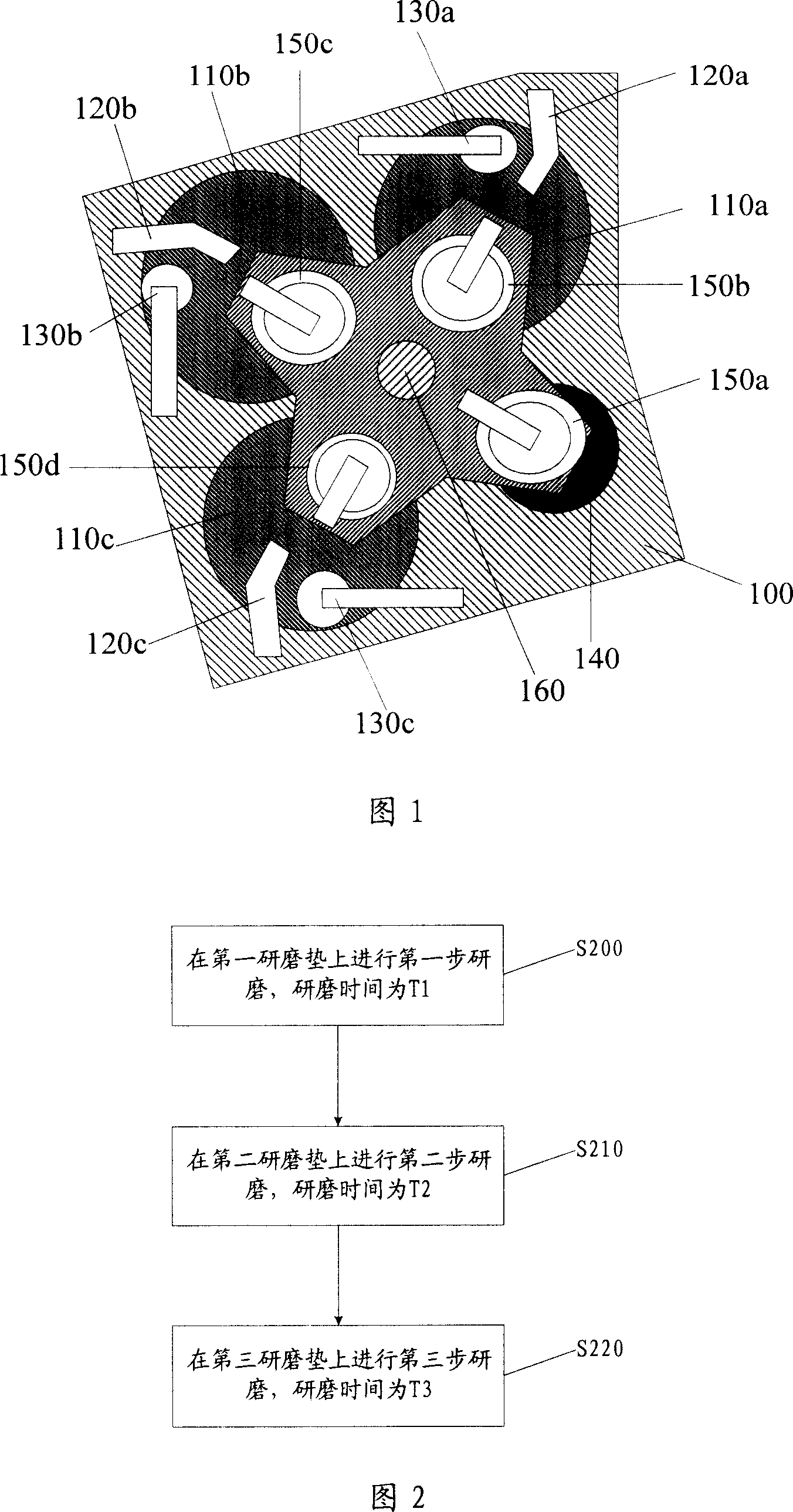

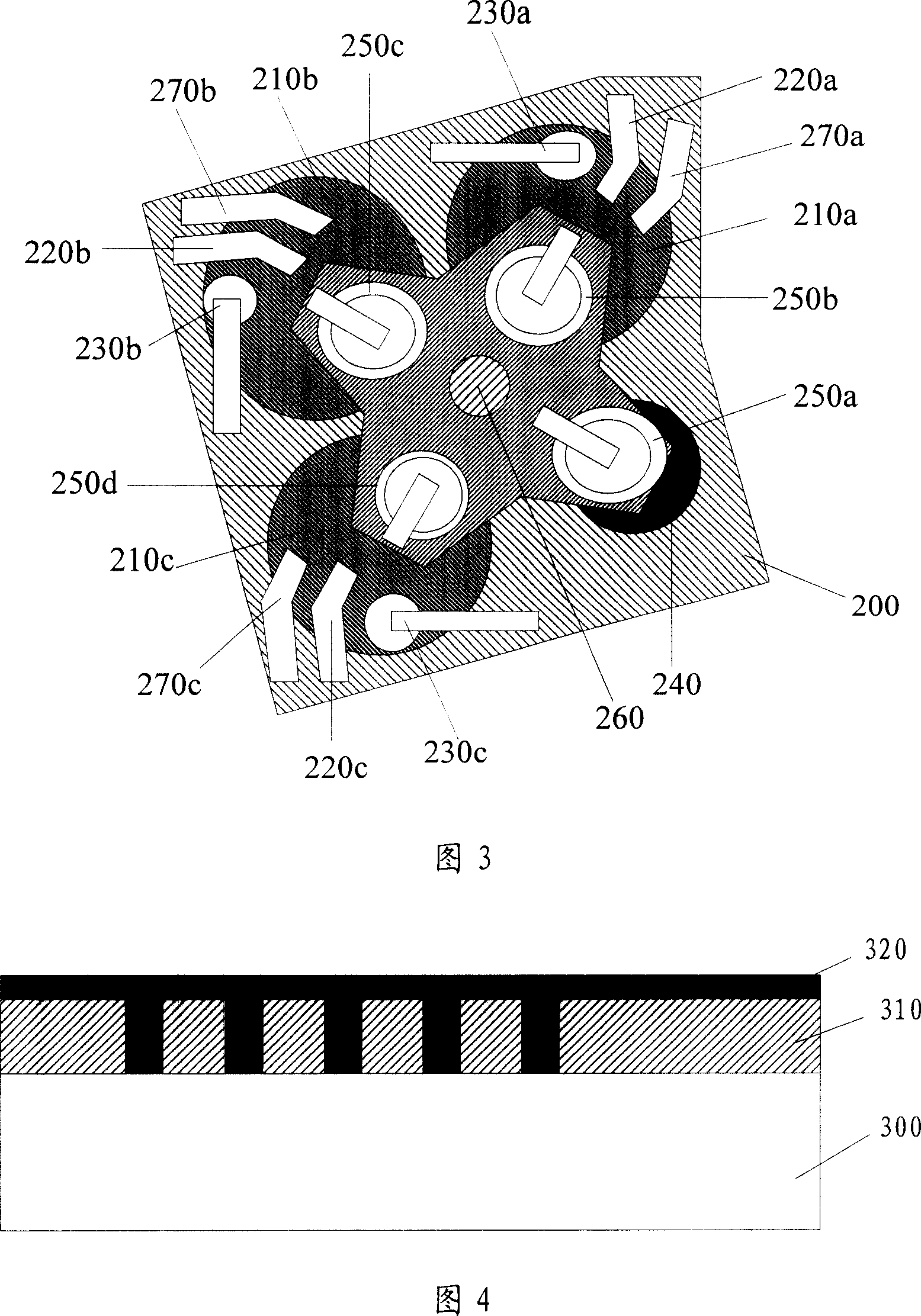

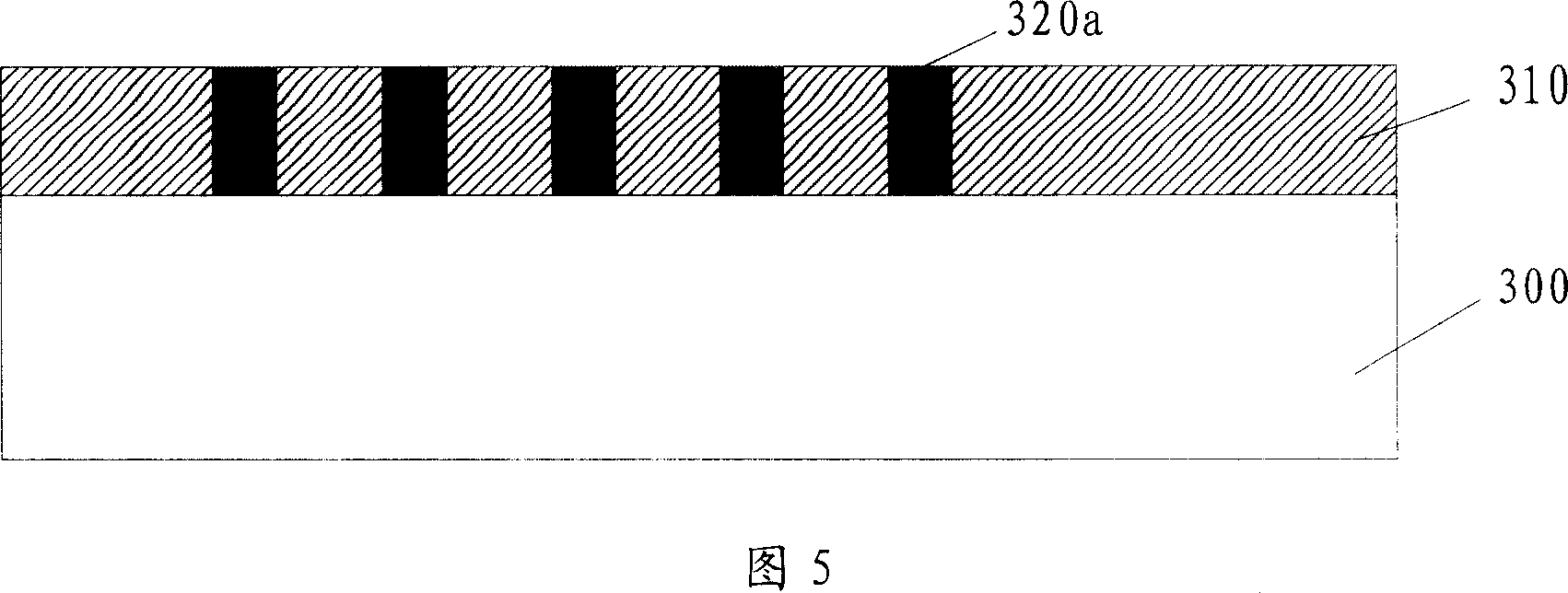

[0023] Chemical mechanical polishing is a planarization method that removes the material layer on the wafer surface through a combination of chemical and mechanical methods. Grinding is generally divided into several steps, for example, coarse grinding, fine grinding, and the like. Each step is done on a different polishing pad. A grinding device will have several grinding pads and several grinding heads, and the wafer will be sucked by the grinding head and the material layer to be ground on the wafer will be pressed down to the surface of the grinding pad, and there will be a grinding pad between the grinding pad and the wafer surface. Liquid (Slurry), through the relative rotation between the polishing pad and the grinding head, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com