Submarine pipeline detecting robot emulation system

A submarine pipeline and simulation system technology, applied in the system field of the simulation technology field, can solve problems such as sensor failure, simulation, and difficulty in simulating various fault situations, and achieve the effects of improving work efficiency, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

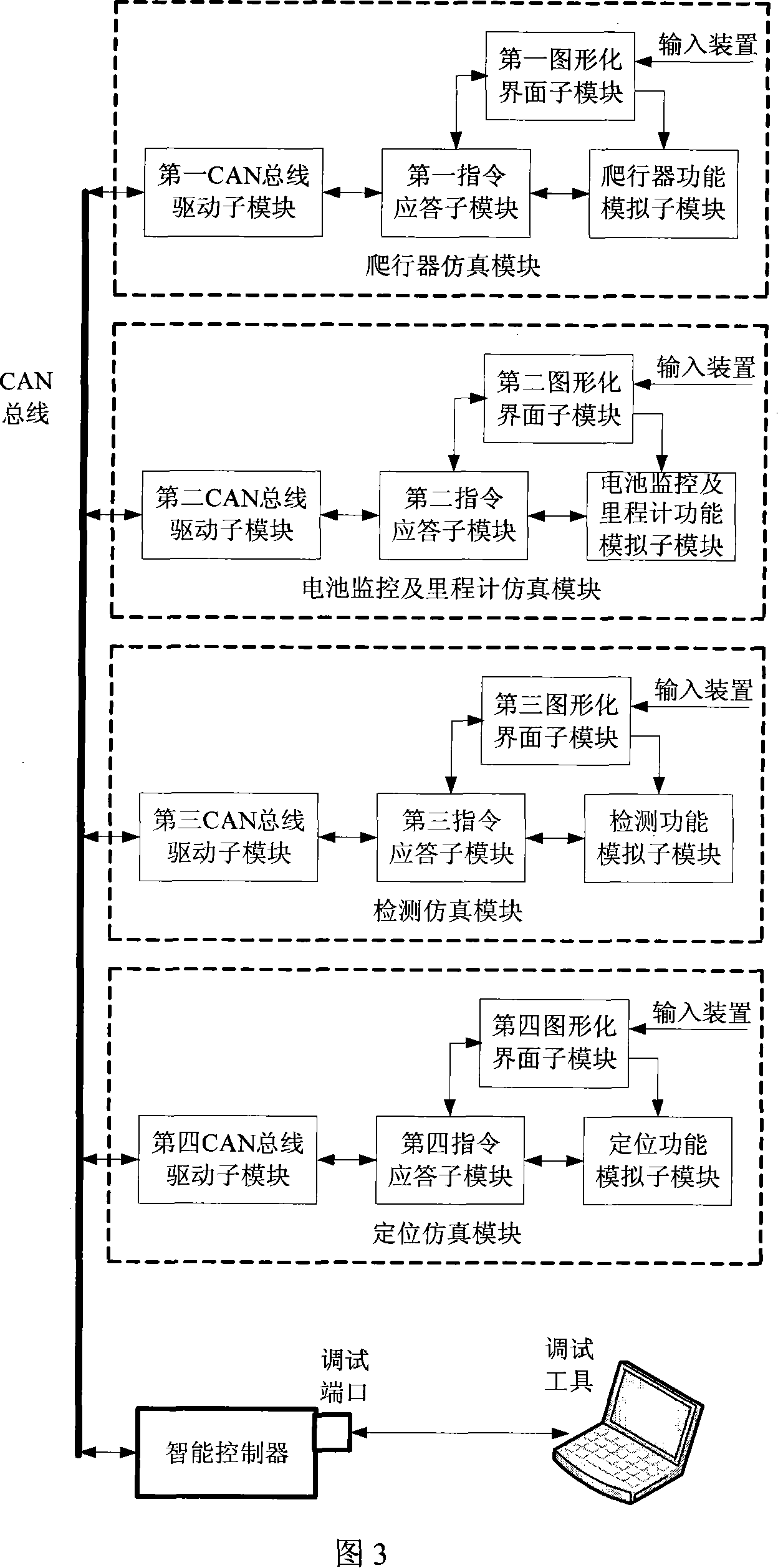

[0028] As shown in Figure 3, this embodiment is used to debug and test the robot intelligent controller, and the parts involved include four simulation modules, as the robot intelligent controller and its debugging tool for being debugged and tested, and various parts CAN bus communication cable between.

[0029] In this embodiment, the submarine pipeline detection robot simulation system uses four main simulation modules: a crawler simulation module, a battery monitoring and odometer simulation module, a detection simulation module and a positioning simulation module. As shown in Figure 3.

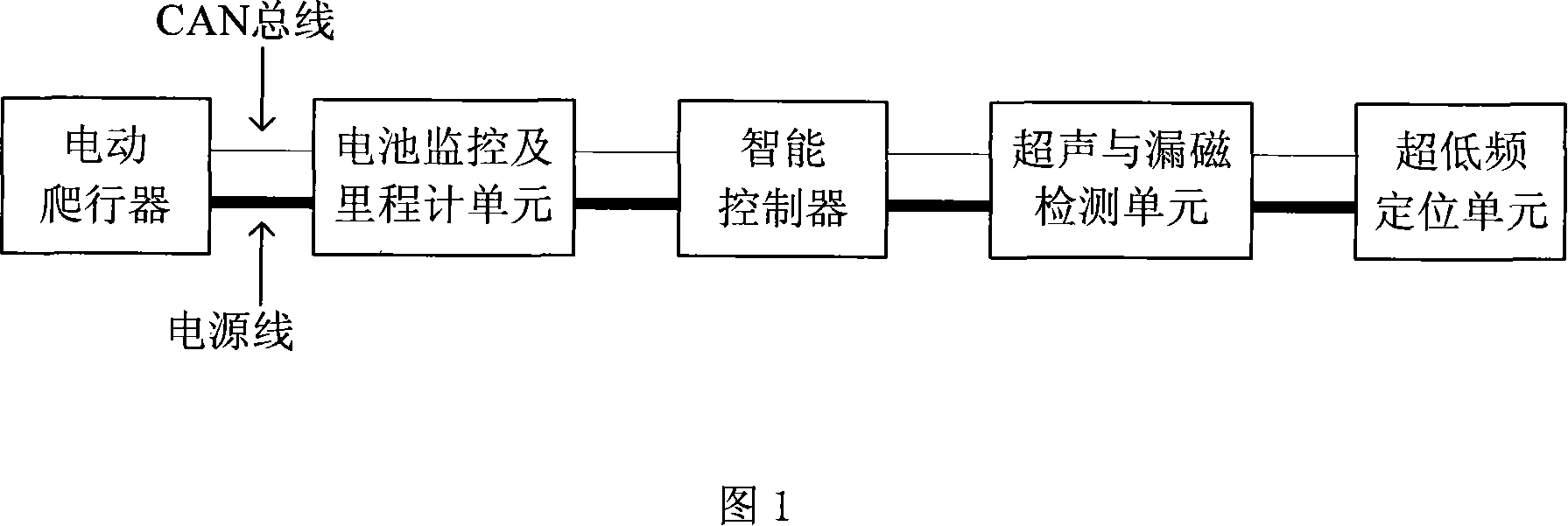

[0030] Among them, the crawler simulation module simulates the function and performance of the robot electric crawler, the battery monitoring and odometer simulation module simulates the function and performance of the robot battery monitoring and odometer unit, and the detection simulation module simulates the function and performance of the robot ultrasonic and magnetic flux leakage mon...

Embodiment 2

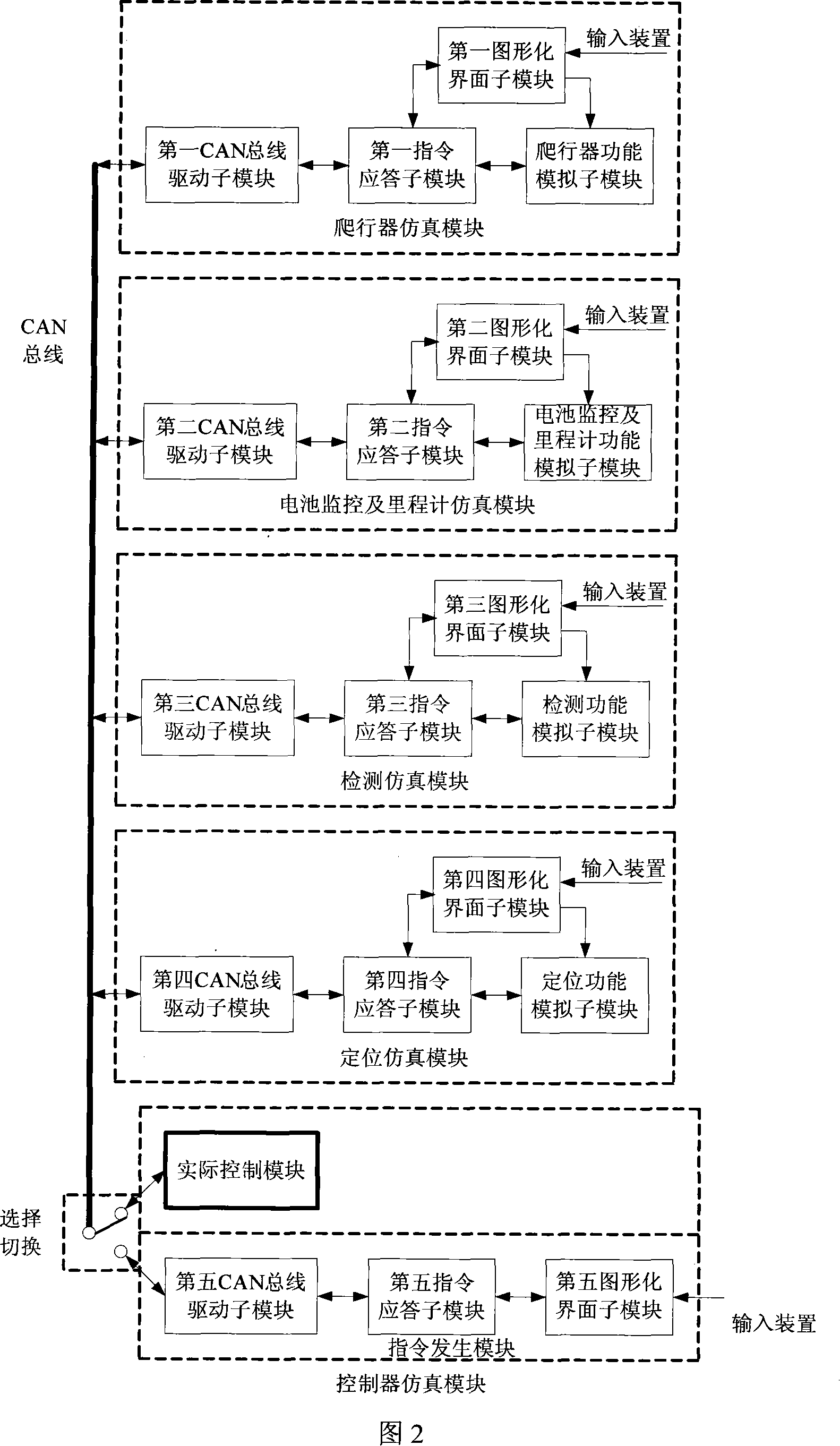

[0042] As shown in Fig. 2, this embodiment is used for the teaching and training of operators and new developers of submarine pipeline inspection robots. The parts involved include all five simulation modules, as well as the CAN bus communication cables between the parts.

[0043] The crawler simulation module, battery monitoring and odometer simulation module, detection simulation module, positioning simulation module, and controller simulation module constitute a complete system to simulate the working conditions of the entire robot to help operators and new developers understand deeply The functions of each unit of the robot and the timing relationship and logical relationship in the control process.

[0044] The working process of the crawler simulation module, the battery monitoring and odometer simulation module, the detection simulation module, and the positioning simulation module are the same as those in the first embodiment, and will not be repeated here.

[0045] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com