Double groove conjoined angular contact ball bearing

An angular contact ball bearing and one-piece technology, which is applied in the field of radial angular contact ball bearings, inertial instruments, and double-groove conjoined angular contact ball bearings, can solve the problem of difficult product qualification rate guarantee, unstable rotation of the rotating system, and Shaft position instability and other problems, to achieve the effect of reducing assembly difficulty, increasing processing difficulty, and fewer types of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

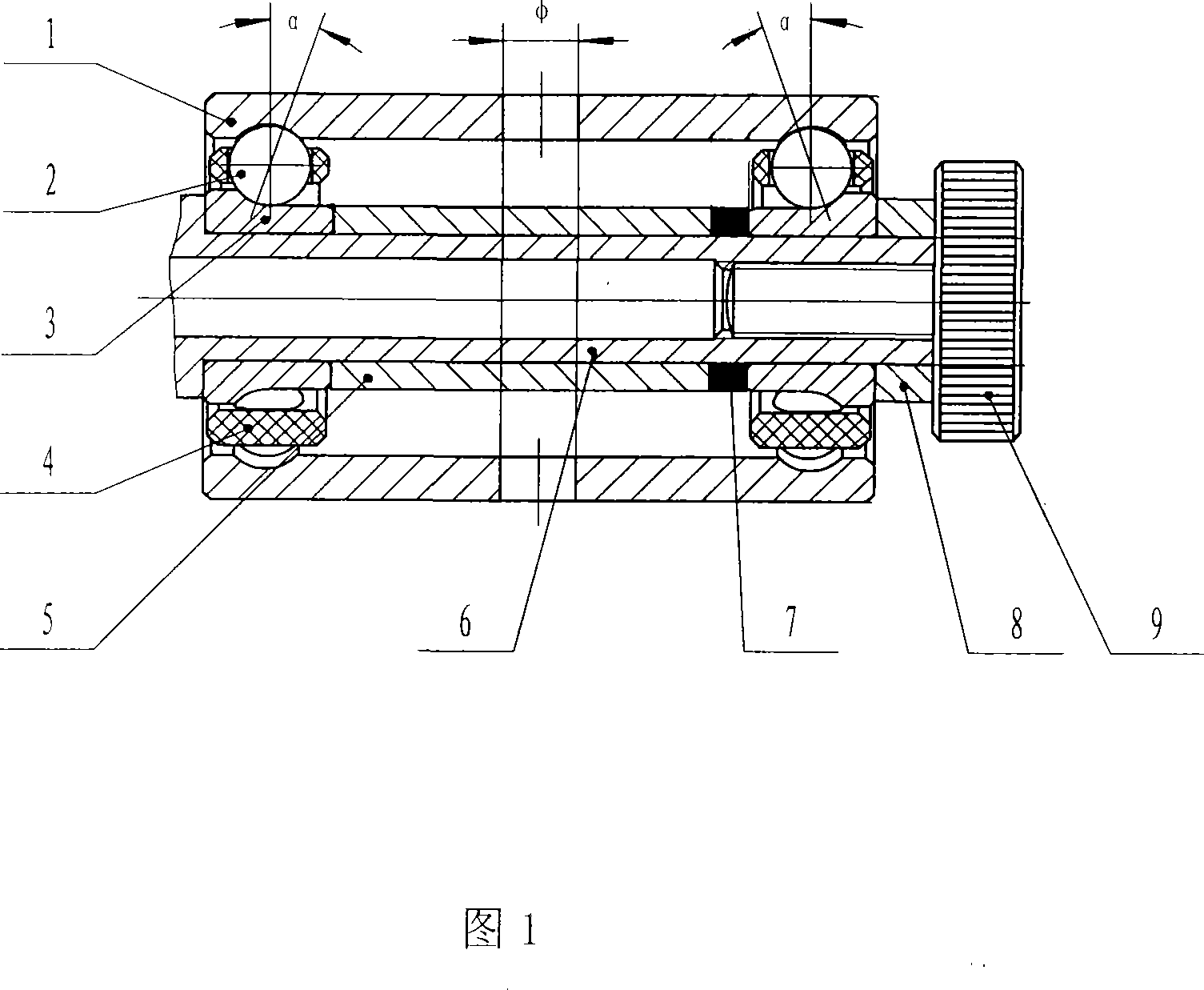

[0013] As shown in Figure 1, a double-groove conjoined angular contact ball bearing includes a bearing outer ring 1, two rows of bearing steel balls 2, two bearing inner rings 3, two cages 4, and an inner ring bushing 5 And an adjusting washer 7, there is an annular raceway at both ends of the bearing outer ring 1, corresponding to the raceways of the two bearing inner rings, and forming a contact angle α; the inner ring bushing 5, the shaft 6 shoulder and the adjustment The washer 7 locks the inner ring 3 of the bearing, and the required preload of the bearing can be achieved by adjusting the thickness of the washer 7 . Axle 6, process washer 8 and process screw 9 form the detachable conjoined bearing. There is a through hole φ in the radial center of the outer ring of the bearing, which is used to feel or test the axial preload of the bearing.

[0014] The material of the cage 4 can be metal or non-metal as required. Shaft 6 can be used as a drive shaft or a process shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com