Semi-penetrating semi-reflective liquid crystal display device and manufacturing method thereof

A liquid crystal display panel, semi-transparent and semi-reflective technology, which is applied in the direction of exposure devices, optics, instruments, etc. in the photo-plate making process, can solve the problem of low compatibility, and achieve the effect of low cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

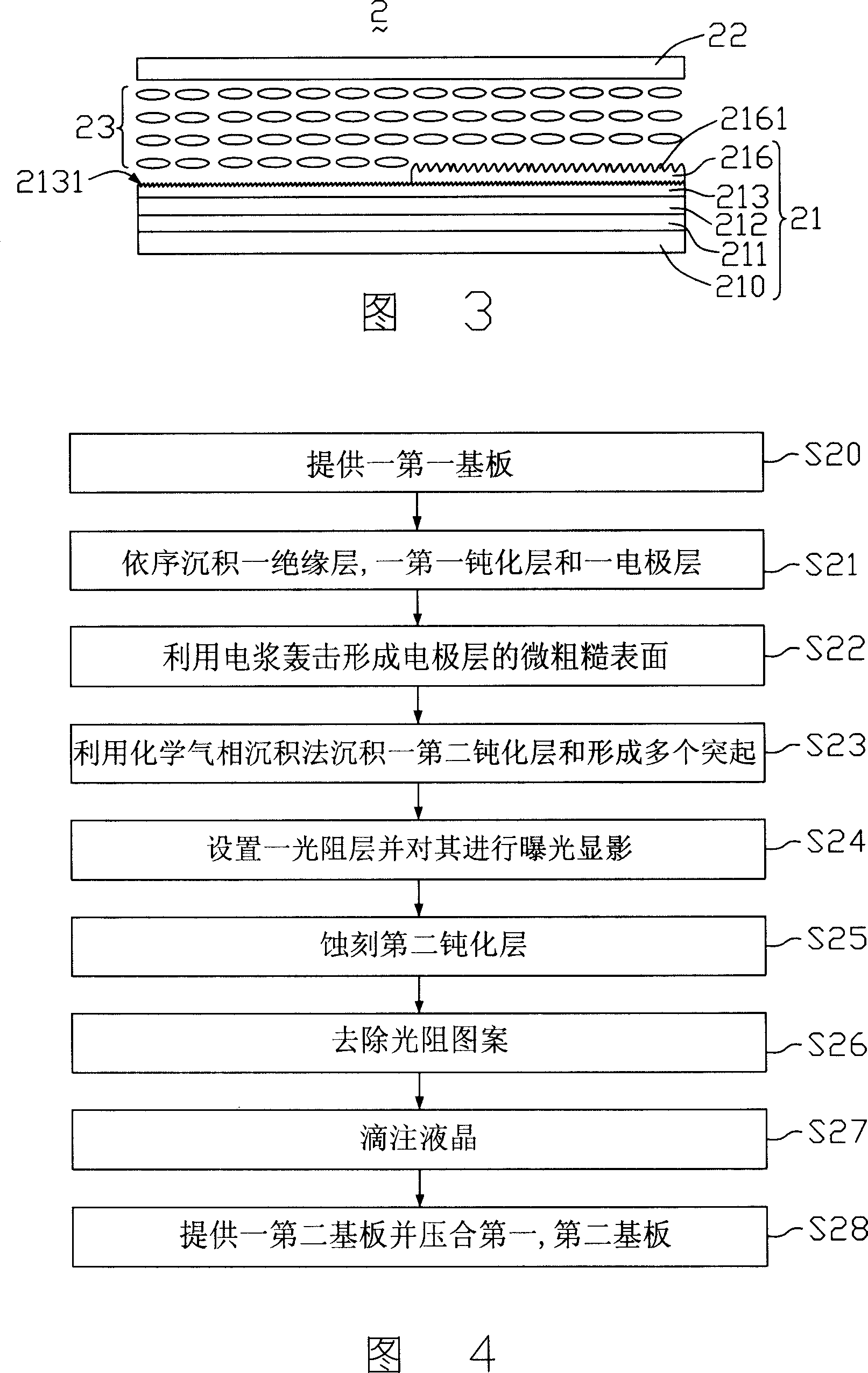

[0031] Please refer to FIG. 3 , which is a schematic structural diagram of the first embodiment of the transflective liquid crystal display panel of the present invention. The transflective liquid crystal display panel 2 includes a first substrate 21 , a second substrate 22 and a liquid crystal layer 23 sandwiched between the first and second substrates 21 and 22 , which are oppositely disposed. The first substrate 21 includes a glass base 210 and an insulating layer 211 , a first passivation layer 212 , an electrode layer 213 and a second passivation layer 216 stacked on the glass base 210 in sequence.

[0032] The electrode layer 213 is an indium tin oxide transparent electrode, the second passivation layer 216 is amorphous silicon nitride, the region corresponding to the second passivation layer 216 is a reflective region, and the electrode layer 213 is not covered by the first passivation layer. The area corresponding to the part covered by the second passivation layer 216...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com