Frequency conversion magnetic levitation compression expansion engine set

A technology of compression expansion and magnetic levitation, which is applied to compressors, compressors using turbines, refrigerators, etc., can solve the problems of complex structure of air conditioning units, failure to obtain expansion work, troublesome maintenance, etc., so as to save oil lubrication system, Reduce frictional power consumption and save material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

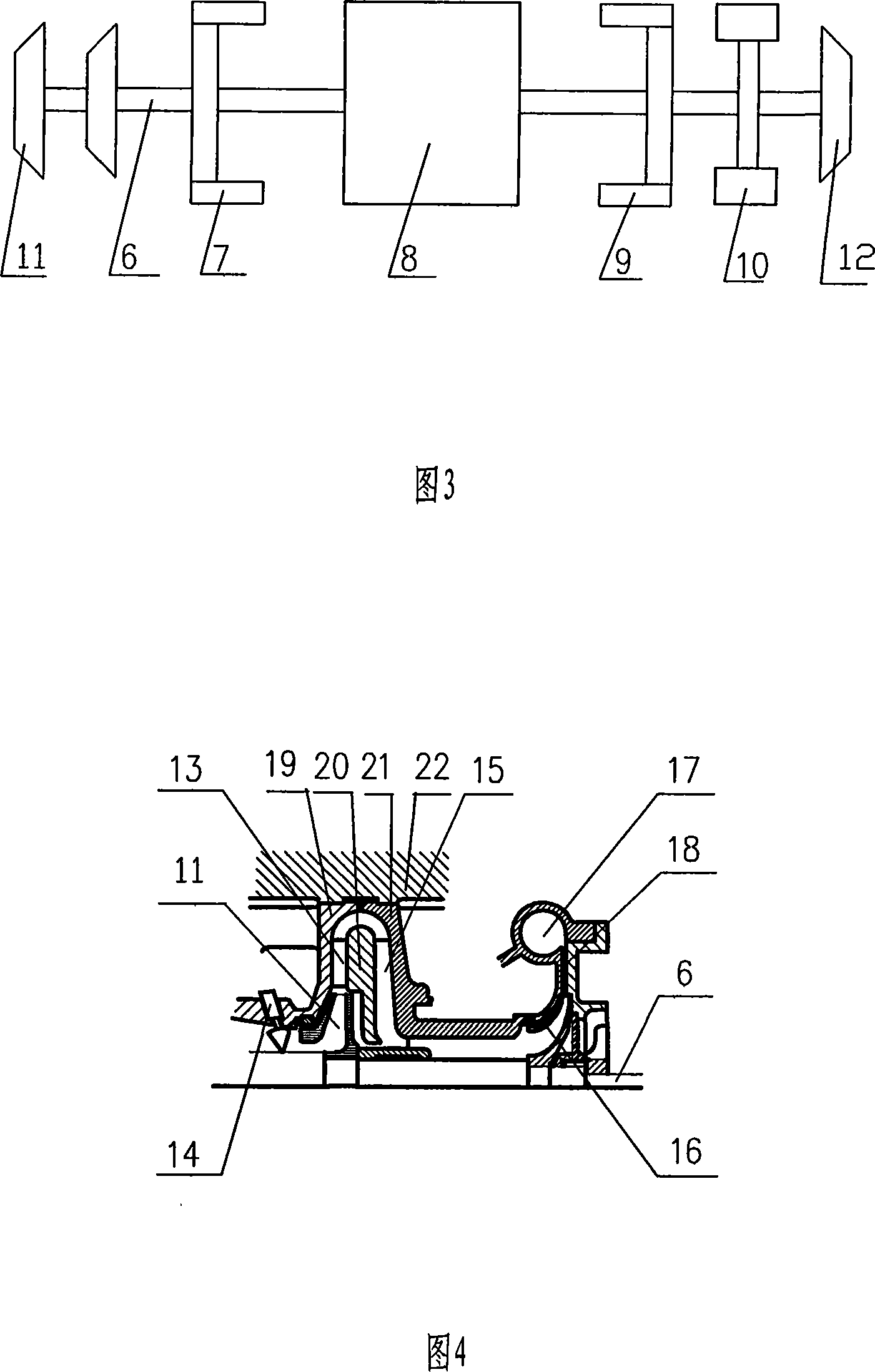

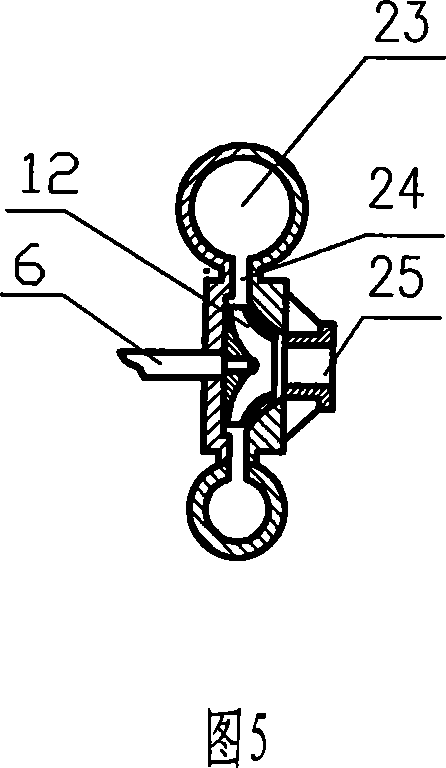

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

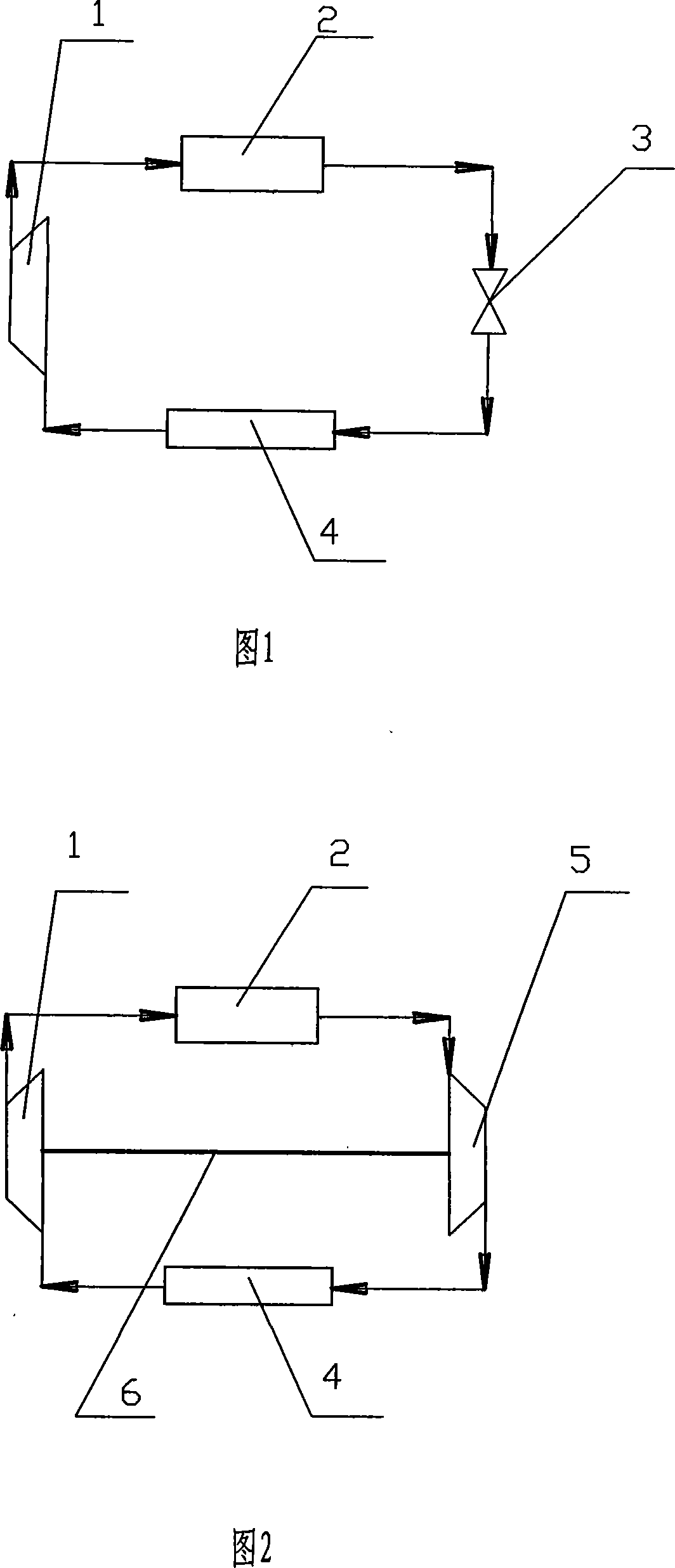

[0029] See Figure 1

[0030] Fig. 1 is a working principle diagram of the prior art. In Fig. 1, the air-conditioning and refrigeration system is connected by a combination of compressor 1, condenser 2, throttling mechanism 3 and evaporator 4, and the refrigerant flowing through the throttling mechanism 3 is an isenthalpic process, which only changes the pressure of the refrigerant, temperature parameter, the work of expansion cannot be obtained.

[0031] Due to the high rotation speed of the centrifugal compressor 1, lubricating oil is required between the drive shaft and the bearing of the conventional compressor 1 to reduce friction and wear, and at the same time take away the heat of friction, requiring a complex lubrication system. The structure makes the structure of the air conditioning unit complex, consumes a lot of energy, is troubles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com