End-surface mechanical seal structure with sharkskin-imitated surface three-dimensional shape

A technology of end face mechanical seal and three-dimensional shape, which is applied in the direction of engine seal, mechanical equipment, engine components, etc., to reduce wear, prevent adhesion, and reduce frictional power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

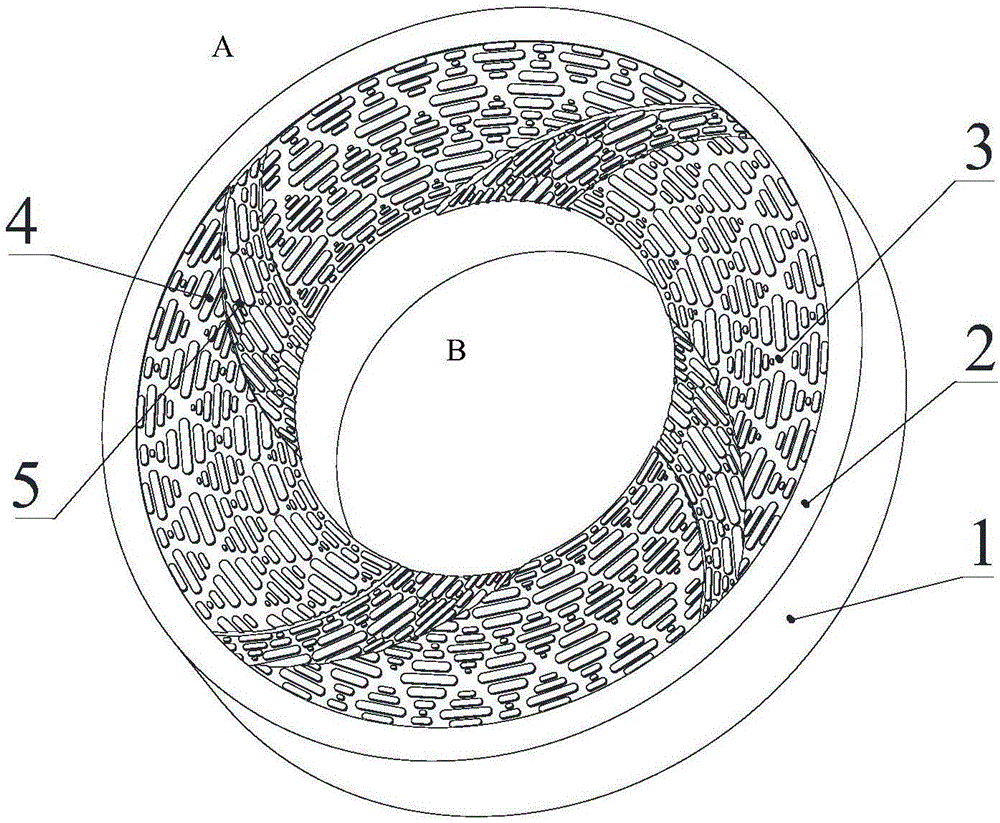

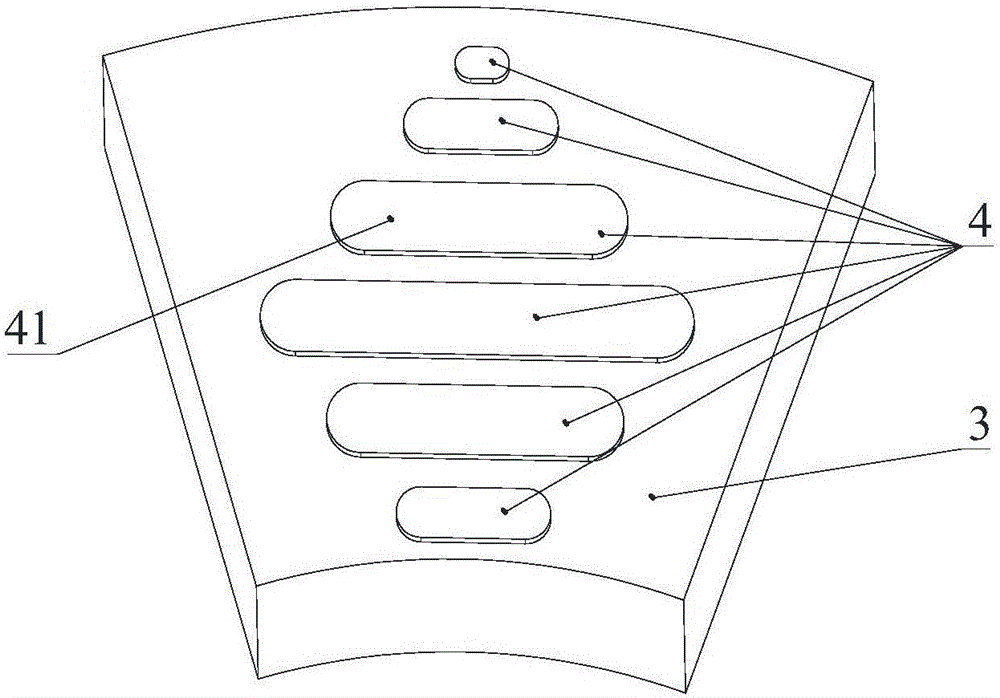

[0024] Embodiment 1 The end face mechanical seal structure imitating the three-dimensional shape of the shark skin surface according to the present invention includes a moving ring and a static ring as a mechanical seal, and the outer end of the sealing end face of the moving ring and the static ring 1 As the high-pressure side A is the upstream, and the inner end of the sealing end face is the low-pressure side B, which is the downstream. In the moving ring or the static ring, at least one sealing end face upstream of the high-pressure side is provided with a closed sealing dam 2, and on the surface of the sealing end face Several upstream pumping grooves 5 are evenly distributed in the circumferential direction, the first end of the upstream pumping groove 5 extends to the high pressure side A of the sealing end surface, and the second end extends to the low pressure side B of the sealing end surface; two adjacent upstream pumping grooves The area between 5 is the sealing wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com