Method for making construction material two-side surface light extraction and LED surface light source for lighting

A building decoration material, LED surface light source technology, applied in the direction of plane light source, electroluminescence light source, light source, etc., can solve the problems of single light source, high cost, poor decorative effect, etc., to achieve colorful pictures, enhance transparency, maintain aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

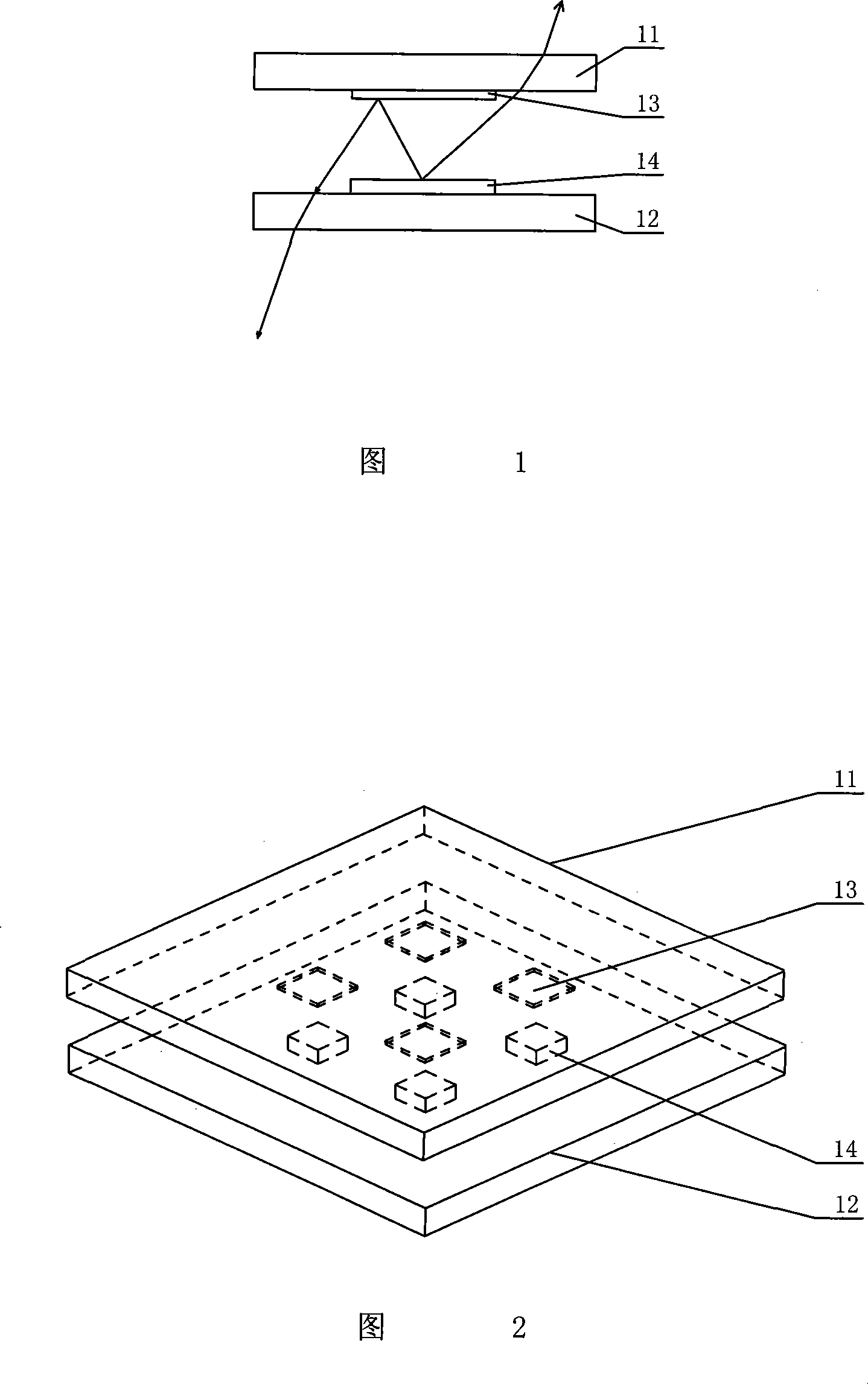

[0052] The structure of using an optical thin film to realize double-sided light emission on the upper substrate is shown in Fig. 2 .

[0053] In Fig. 2, according to the installation position of the LED point light source 14 on the lower transparent substrate 12, a reflective film 13 is coated on the corresponding position of the upper transparent substrate 12, and a part of the light emitted by the LED is reflected back to the lower transparent substrate 12 when encountering the reflective film. , to emit light in the lower substrate; and another part of the light emitted by the LED, when it encounters a place without a reflective film, is directly transmitted from the upper transparent substrate, thereby achieving the effect of double-sided light emission.

Embodiment 2

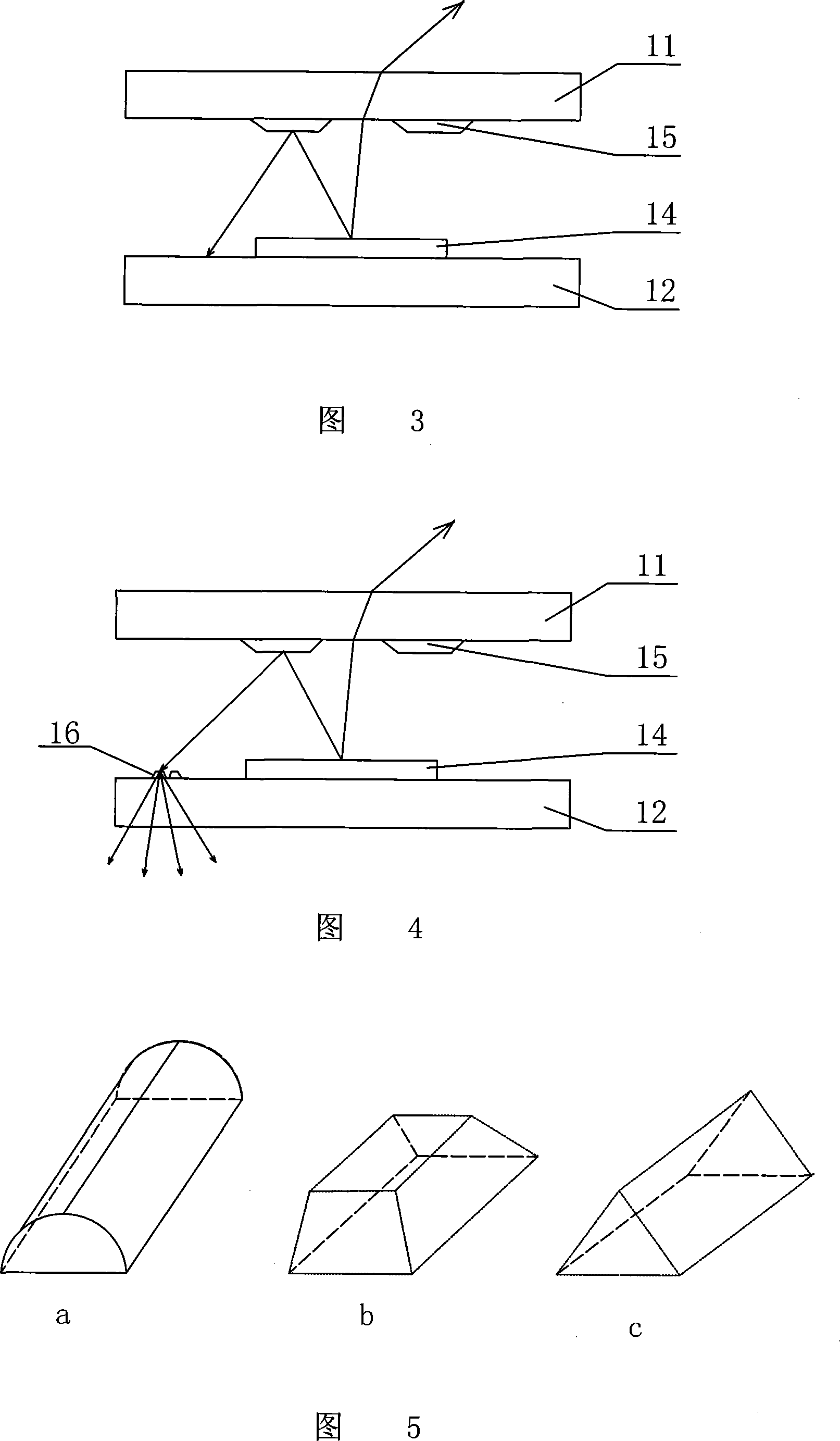

[0055] The structure of the upper substrate using a reflective / diffusing structure to realize double-sided light output is shown in Figure 3 .

[0056] In Fig. 3, several inverted trapezoidal reflective structures 15 are etched on the upper transparent substrate 11 corresponding to the position of the LED point light source 14, and a certain gap is left between each inverted trapezoidal structure; The inverted trapezoidal reflective structure reflects back to the lower transparent substrate 12 to achieve the effect of double-sided light emission.

[0057] In this solution, by changing the geometric dimensions such as the angle of the inverted trapezoid, the direction of light reflection can be adjusted, so that most of the reflected LED light is emitted from the lower transparent substrate, so that the double-sided light emission effect of the light source is better.

Embodiment 3

[0059] Both the upper and lower substrates adopt optical reflective / diffusion structures to realize double-sided light emitting structures, as shown in FIG. 4 .

[0060] In Fig. 4, in order to enhance the light extraction rate of the lower transparent substrate, a certain pattern is etched on the lower transparent substrate or a light-enhancing film 16 is coated to increase the light intensity of the lower transparent substrate and reduce the difference in light intensity between the upper and lower transparent substrates. It helps to achieve the uniformity of double-sided light output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com