Exterior wall thermal insulation brick and manufacturing method thereof

A technology for external wall insulation and thermal insulation components, which is applied to other household appliances, building materials, household components, etc., can solve the problems of low bonding strength, long construction time, and easy to be affected by the climate environment, and achieves high bonding strength. Working hours, beautiful appearance and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

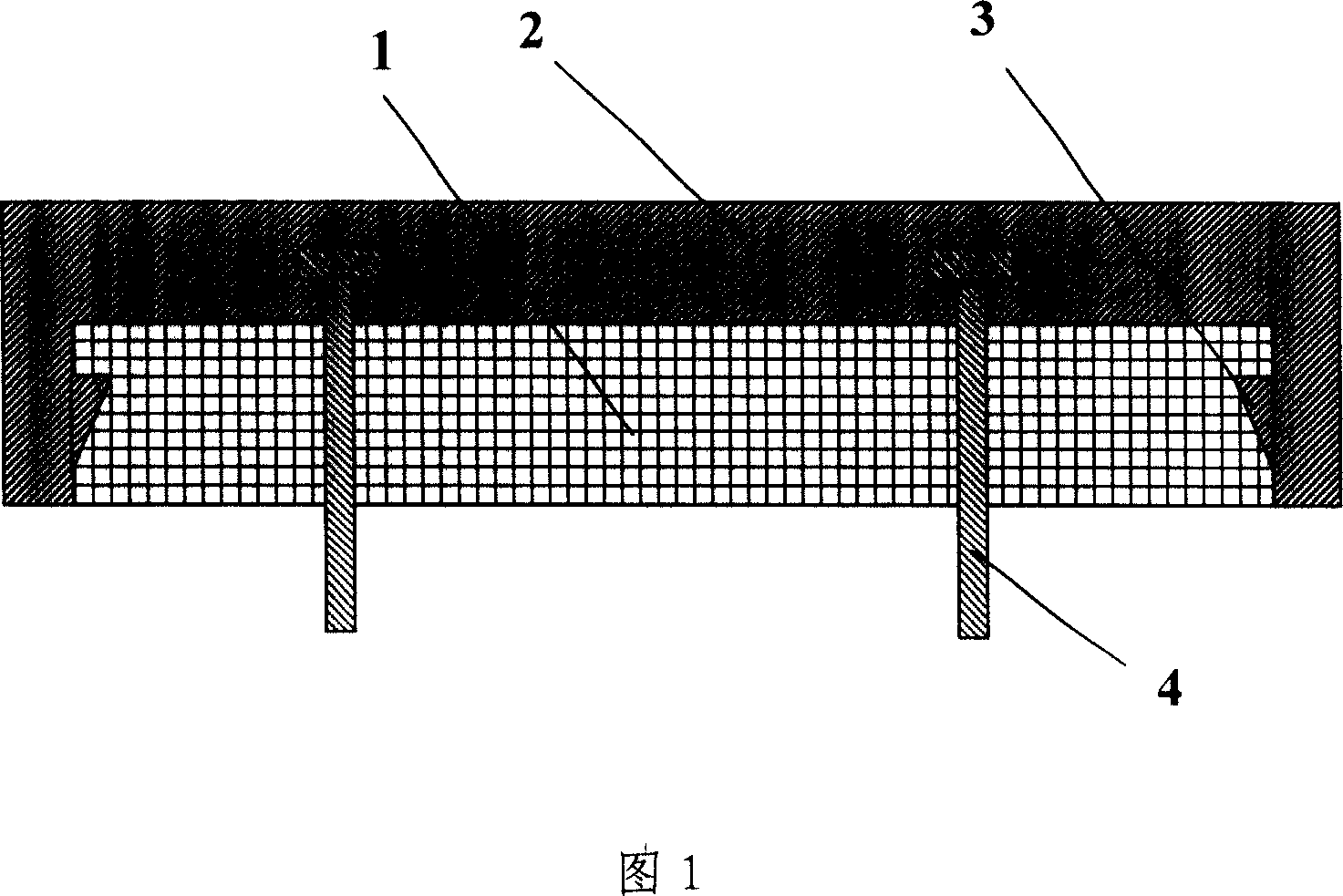

[0014] As shown in Figure 1, an exterior wall insulation brick of the present invention is composed of an insulation component 1 and a wall component 2, wherein the wall component 2 is block-shaped, and an inner cavity is arranged inside the wall component 2. The thermal insulation component 1 is filled in the inner cavity, the thermal insulation component 1 is made of expandable polystyrene material, and a plurality of barbs 3 are arranged in the side wall of the inner cavity, and any one of the barbs 3 is embedded in the inner cavity. Insulation component 1.

[0015] Further, the wall component 2 is a box made of ceramic tiles, or stones, or plastic blocks, or wood blocks, or aluminum sheets.

[0016] Further, the said wall member 2 is fixedly provided with a fastener 4 .

[0017] Further, the said fastener 4 is an expansion screw.

[0018] The present invention also provides a method for manufacturing the above-mentioned thermal insulation bricks for external walls. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com