IV type concave holographic grating production process

A holographic grating and process flow technology, applied in diffraction grating and other directions, can solve the problems of unsatisfactory light collection efficiency of the spectrometer system, and achieve the effects of novel production process flow, shortened production cycle and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

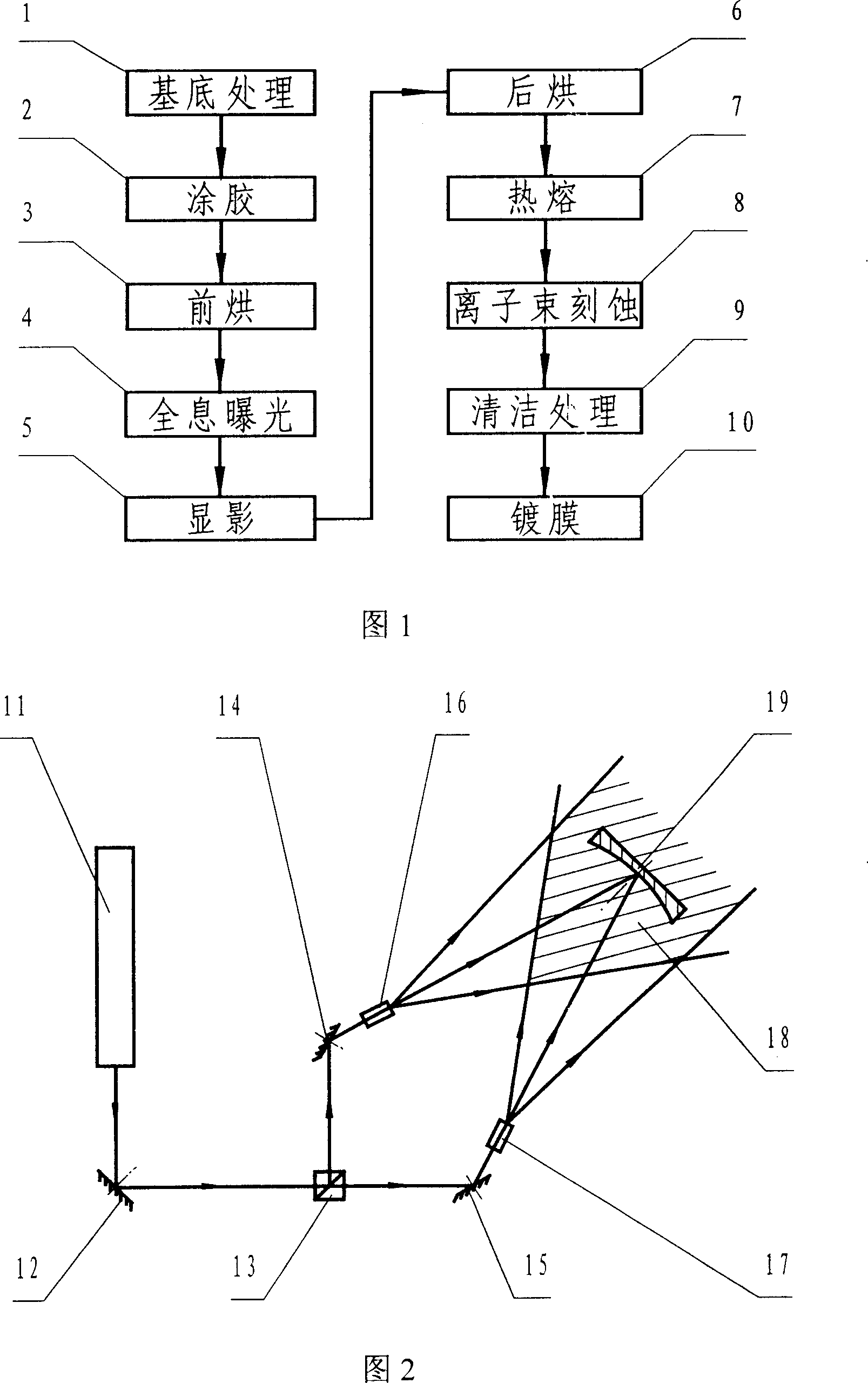

[0011] The present invention is implemented according to the steps of the preparation process flow chart shown in Fig. 1, specifically as follows:

[0012] 1. Clean the concave K9 glass substrate without bubbles, scratches and polished with calcium carbonate;

[0013] 2. Coat Shiply1805 positive photoresist with a thickness of 300-700nm on the concave K9 glass substrate. The thickness of the adhesive layer is realized according to the density of the groove and the control of the speed of the centrifuge;

[0014] 3. Put the photoresist-coated grating substrate into the oven for pre-baking, raise the oven temperature to 90°C, start timing, and take it out after 30 minutes;

[0015] 4. Expose the grating substrate in the interference field for 10-120 seconds, and control the exposure time according to the type of photoresist and the strength of the interference field;

[0016] 5. Put the exposed grating substrate into 5‰ NaOH solution, and develop it at room temperature for 10-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com