Composite thermal insulation energy-saving board

A composite thermal insulation and energy-saving board technology, applied in thermal insulation, building components, covering/lining, etc., can solve the problems of restricting the popularization and application of building energy-saving materials and technologies, poor force capacity, and difficulty in large-scale production in factories, and achieve thermal insulation isolation. The effect of thermal energy saving and sound insulation is good, the building comfort is improved, and the amount of on-site construction is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

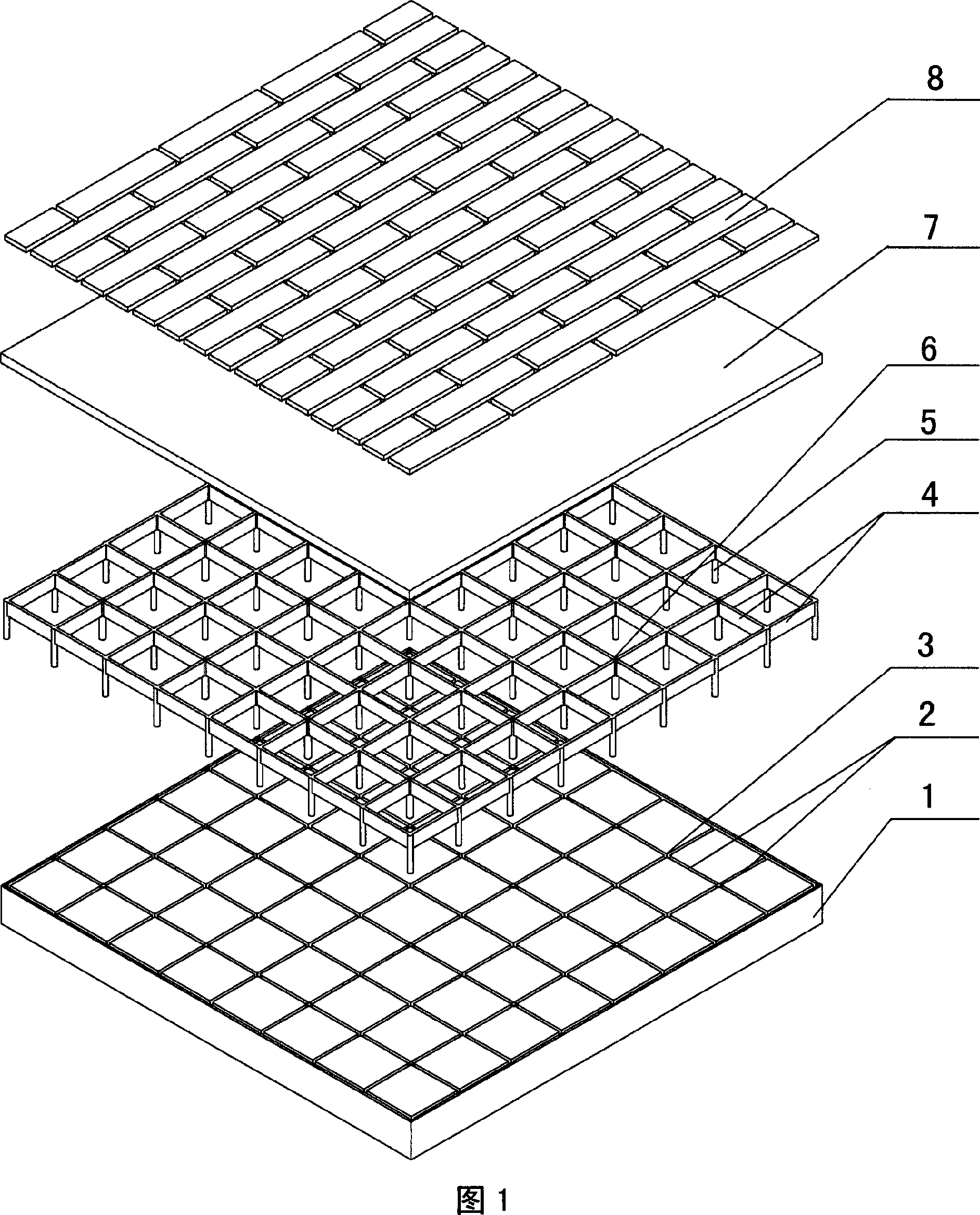

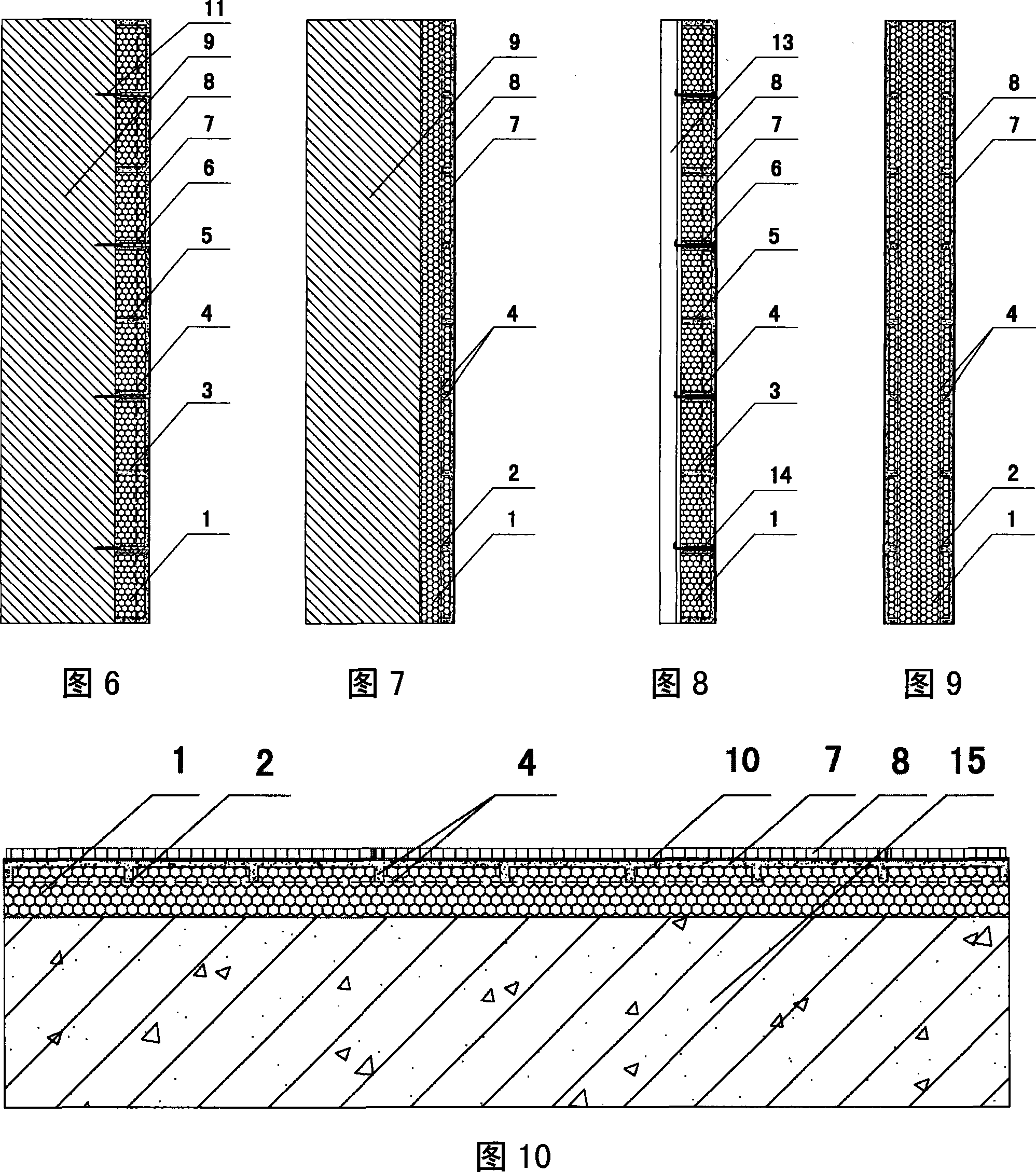

[0017] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0018] As shown in Figures 1 to 4, grooves 2 and holes 3 matching stiffeners 4 and supports 5 are provided on the insulation layer 1, and grooves 2 and holes 3 are formed on the insulation layer 1. Fill and coat the polymer cement mortar with fibers, and form an integral support frame composed of the base layer 7, stiffeners 4 and support body 5 after drying, and directly paste ceramic tiles, stones, etc. on the base layer 7 when it is not dry Layer material, also can be coated with binding layer 10 after base layer 7 is dry and paste surface layer material again, or scrape putty on base layer 7 and do exterior wall paint surface layer, can reserve as required or subsequently process nail hole 6, like this Made into an integral composite exterior wall insulation board. In the composite thermal insulation board, the base layer 7, the stiffeners 4, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com