Method for preparing spinel ferrite powder

A spinel ferrite and ferrite technology, which is applied in the field of preparation of spinel ferrite powder, can solve the problems of affecting the health of workers, affecting the service life of equipment, increasing the reaction cost, etc. Physical health and environmental protection, easy to control, less toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

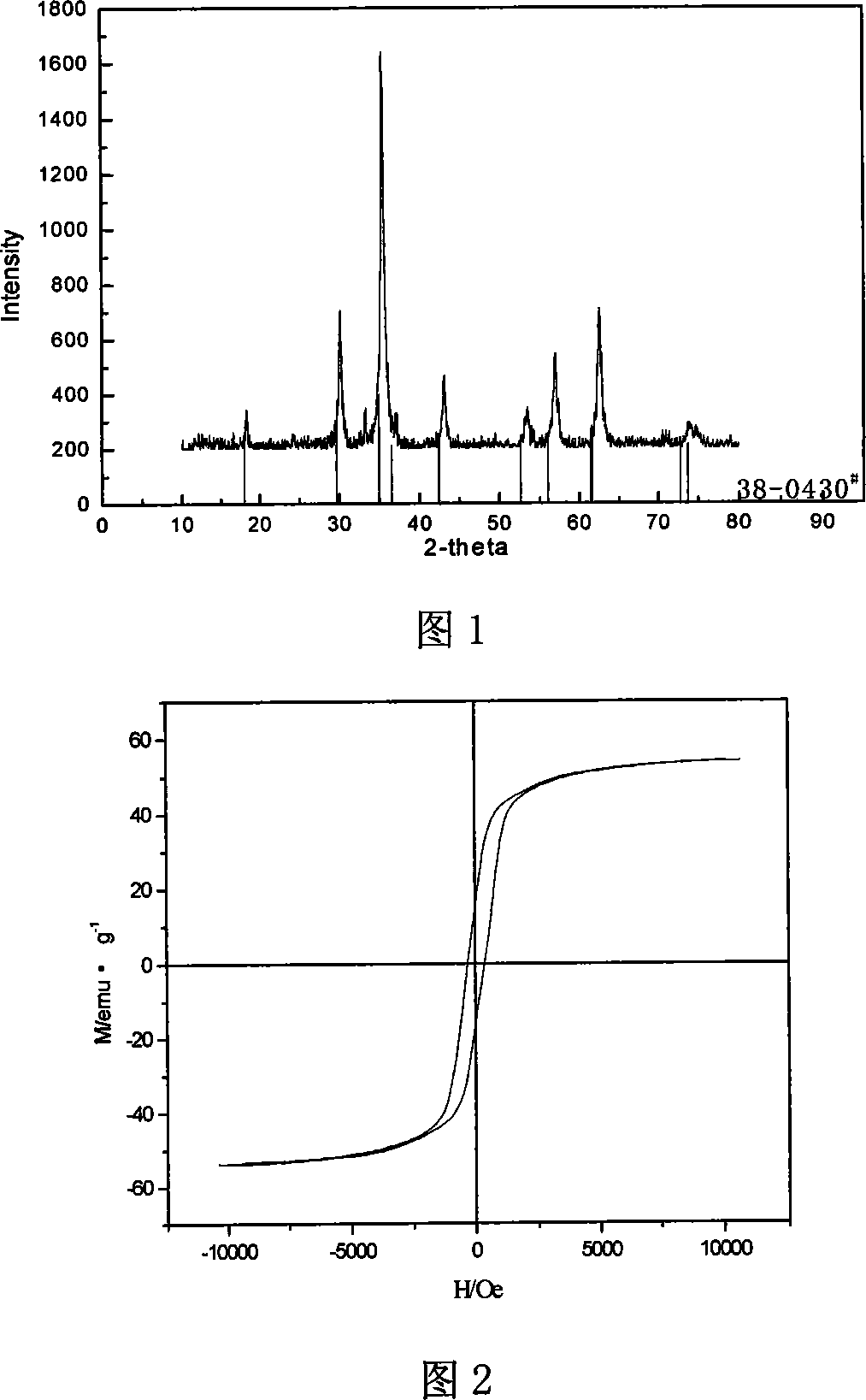

Image

Examples

Embodiment Construction

[0022] The following examples describe the present invention in more detail:

[0023] 1) According to spinel ferrite MnFe 2 o 4 The stoichiometric ratio of the various components weighed Mn(NO 3 ) 2 3.579g (made into 10ml aqueous solution), Fe(NO 3 ) 3 8.008g mix well.

[0024] 2) According to the ferrite composition, weigh 60ml of egg white and 30ml of distilled water, stir at room temperature until uniform;

[0025] 3) Slowly add the mixed raw materials into the egg white aqueous solution and stir;

[0026] 4) Stir vigorously for 2 hours;

[0027] 5) Put the reactants in a water bath at 80°C, heat and evaporate to dryness;

[0028] 6) Rolling the prefabricated precursor into fine powder and roasting at 500°C for 5 hours;

[0029] 7) quenching of ice-water mixture;

[0030] 8) Dry in a blast oven at 100°C to obtain MnFe 2 o 4 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com