Feed mixed emulsifying oil and its producing method

A production method and emulsified oil technology, applied in the field of emulsified oil, can solve the problems of reducing the comprehensive economic benefits of breeding, affecting the normal growth and feeding effect of animals, and the low utilization rate of oil digestion and absorption, so as to improve the comprehensive economic benefits and increase production Performance and feed remuneration, and the effect of reducing farming costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 20kg of corn oil, 25kg of soybean oil, 15kg of coconut oil, 8kg of palm oil, 9kg of peanut oil, 10kg of rice bran oil, 20kg of cottonseed oil, and 30kg of hydroxylated modified soybean lecithin. Pump 7 kinds of raw materials except hydroxylated modified soybean lecithin into the reaction kettle, heat indirectly with steam coil under stirring, when the temperature rises to 55°C, add hydroxylated modified soybean lecithin, after stirring evenly, When the temperature rises to 60°C, pump the raw materials into a 60-mesh pipeline filter for filtration, then use a high-emulsification shearer for high-speed shearing, and then use a high-pressure homogenizer to homogenize at a pressure of 25Mpa and a temperature of 60°C, and then Cool to room temperature to make mixed emulsified oil.

Embodiment 2

[0022] Weigh 25kg of corn oil, 20kg of soybean oil, 10kg of coconut oil, 6kg of palm oil, 10kg of peanut oil, 15kg of rice bran oil, 15kg of cottonseed oil, and 25kg of hydroxylated modified soybean lecithin. Production method is with embodiment 1.

Embodiment 3

[0024] Weigh 25kg of corn oil, 25kg of soybean oil, 20kg of coconut oil, 10kg of palm oil, 10kg of peanut oil, 20kg of rice bran oil, 20kg of cottonseed oil, and 35kg of hydroxylated modified soybean lecithin. Production method is with embodiment 1.

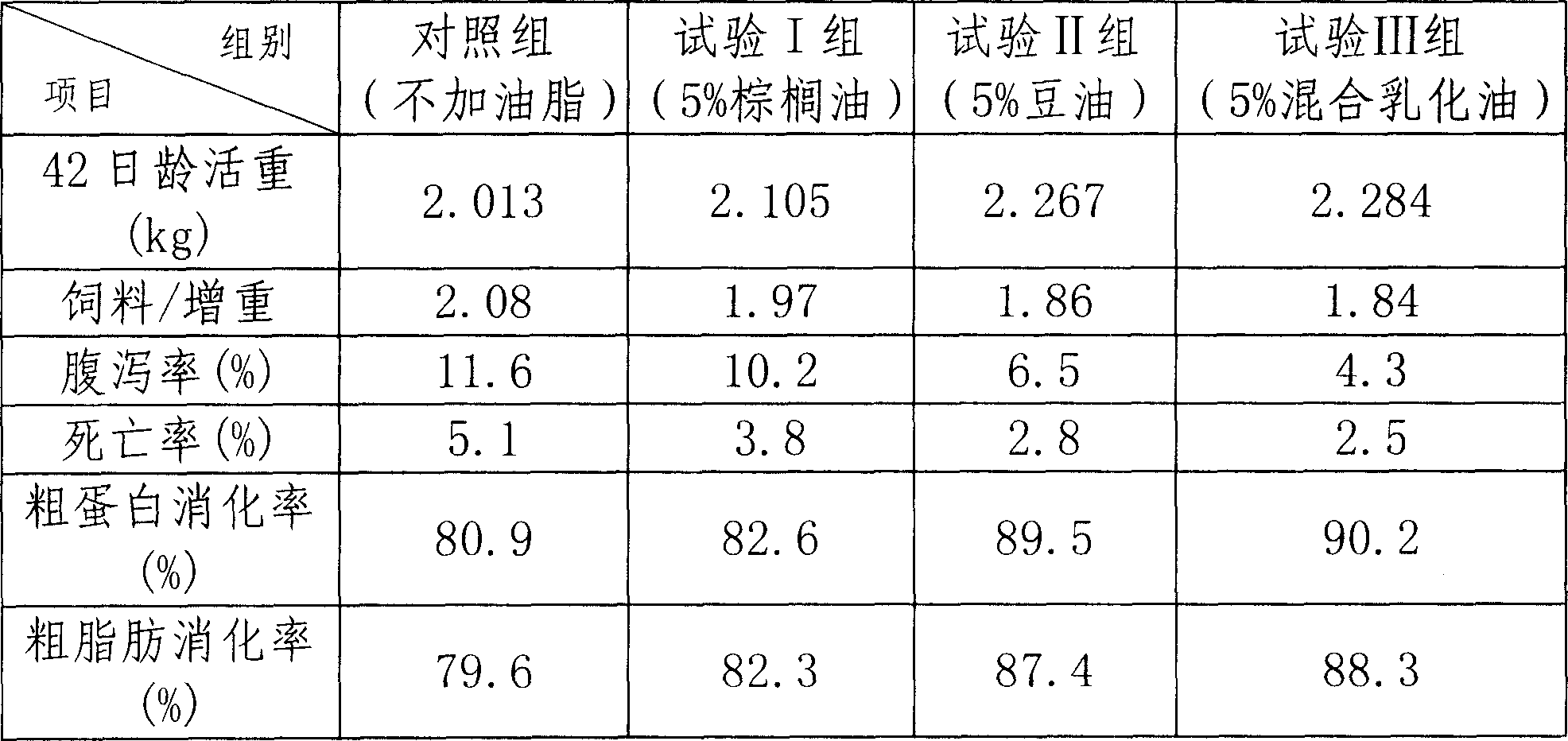

[0025] The following is the test result of the mixed emulsified oil of the present invention with reference to SN / T0801-1999 and GB / T17376-17377.

[0026] Crude Fat 98.3%

[0027] Phospholipids 31.2%

[0028] Moisture 0.10%

[0029] Free fatty acids 7.54%

[0030] Acid value 18.12

[0031] Vitamin E 2.06mg / 100g

[0032] Digestible energy 8645Kcal / Kg

[0033] Metabolizable energy 8232Kcal / Kg

[0034] In the mixed emulsified oil, the composition of fatty acid content is as follows.

[0035] 1:0 (myristic acid) 0.29%

[0036] 1:0 (palmitic acid) 23.21%

[0037] 1:1 (palmitoleic acid) 0.11%

[0038] 1:0 (stearic acid) 4.18%

[0039] 1:1 (oleic acid) 26.10%

[0040] 1:3 (linolenic acid) 4.10%

[0041] 2:0 (Arachidic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com