Long wavelength laser transmitted perpendicular to surface of cavity by using integrated pumping light source

A technology of vertical cavity surface emission and fabrication method, which is applied in the field of long wavelength vertical cavity surface emitting lasers, and can solve the problems of device cost, increased packaging difficulty, difficult temperature characteristics, and difficulty in heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

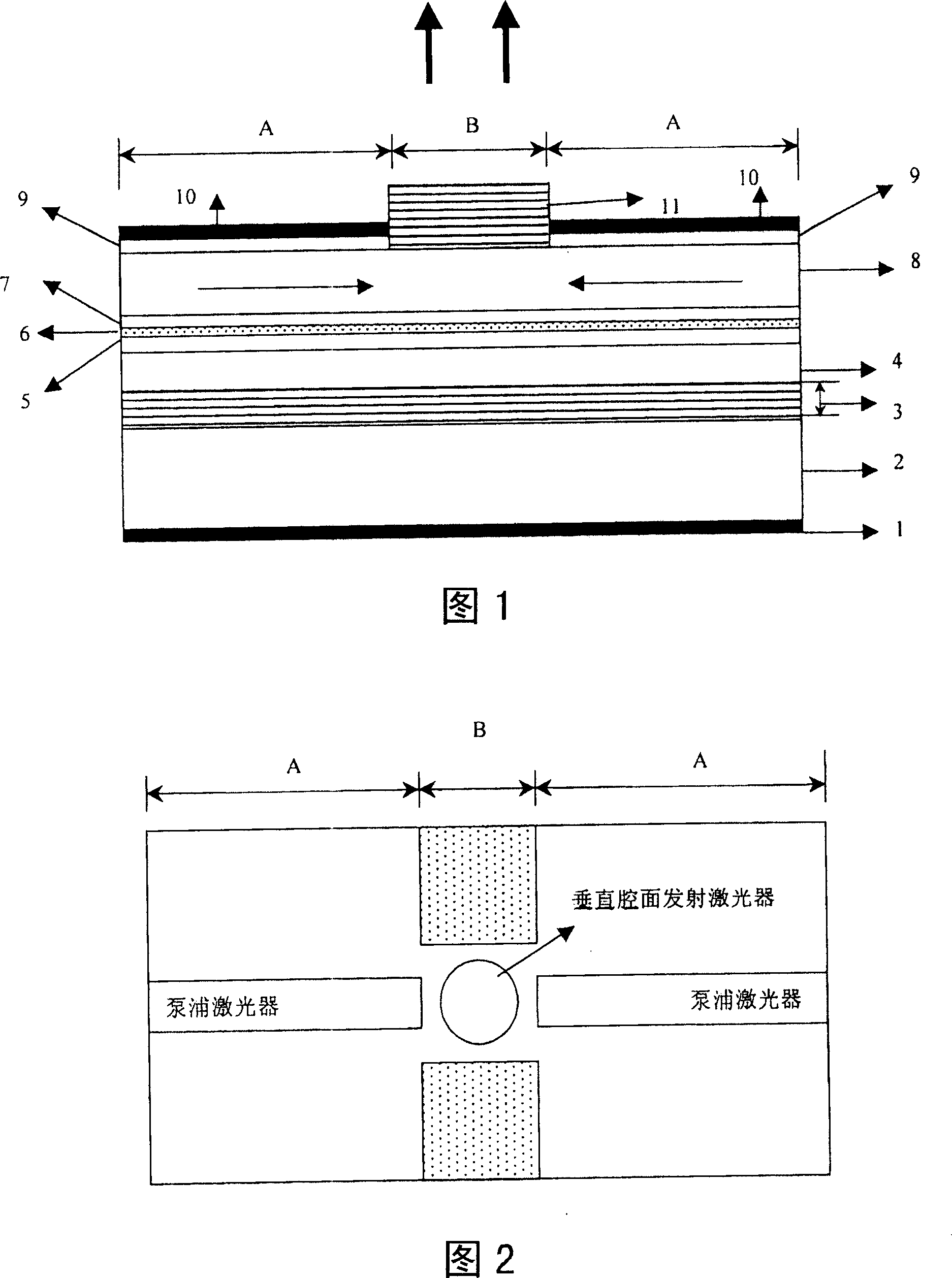

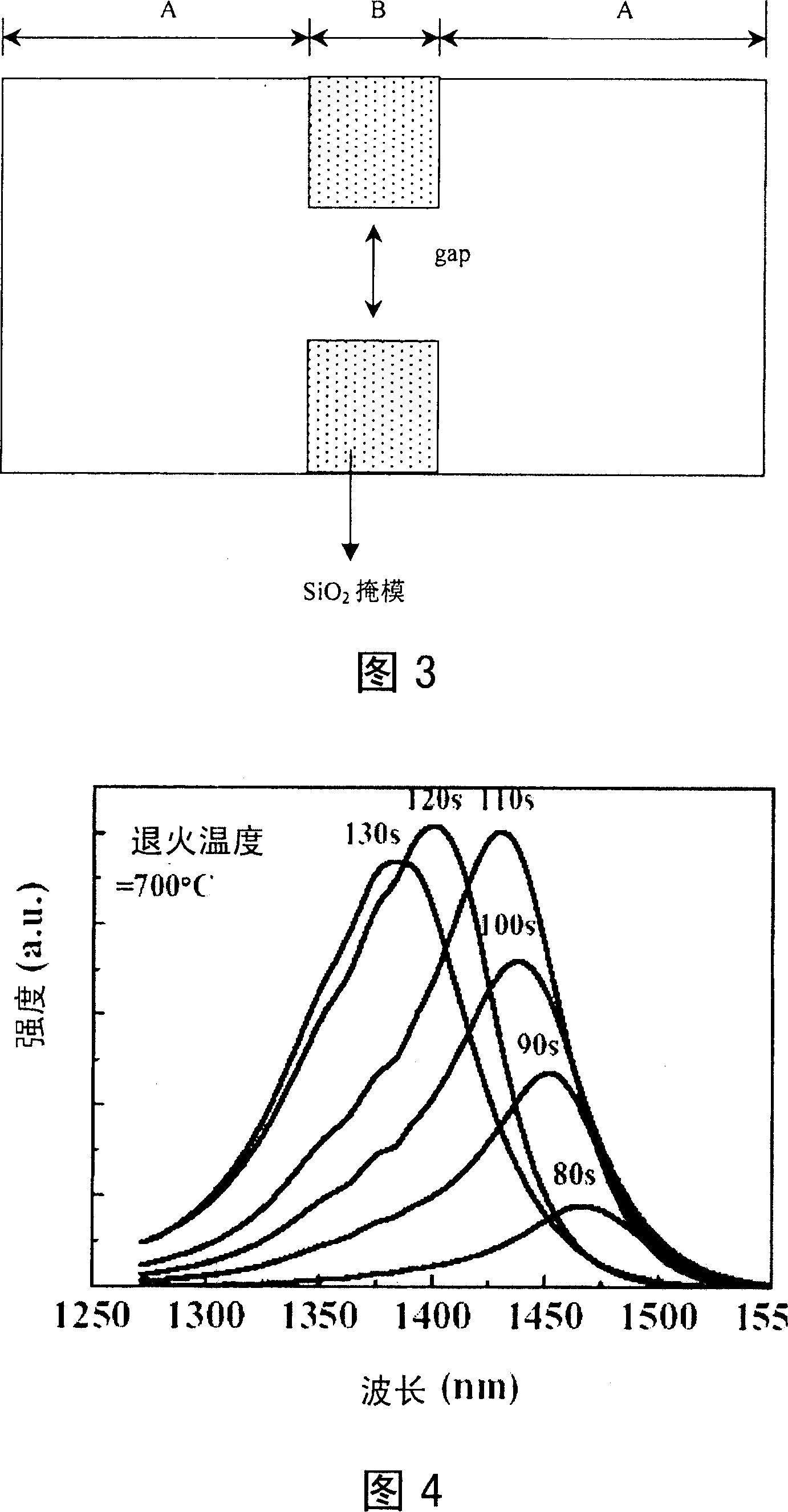

[0079] Please refer to Fig. 1 and Fig. 2, the long-wavelength vertical cavity surface emitting laser structure of the integrated pump light source of the present invention includes: a lower electrode 1, a substrate 2, a lower Bragg reflector (DBR) 3, a lower confinement layer 4, Lower waveguide layer 5 , active region 6 , upper waveguide layer 7 , upper confinement layer 8 , ohmic contact layer 9 , upper electrode 10 and upper Bragg reflector (DBR) 11 .

[0080] The lower electrode 1 is Au-Ge-Ni;

[0081] Substrate 2 is an n-type InP substrate;

[0082] The lower Bragg reflector (DBR) 3 is 40 pairs of AlGaInAs / InP lattice-matched with InP, doped into n-type. It has a larger refractive index difference, a lower conduction band potential difference and a higher thermal conductivity;

[0083] The lower confinement layer 4 is n-type InP;

[0084] The lower waveguide layer 5 is InGaAsP with a bandgap wavelength of 1.2 μm, without doping;

[0085] The active region 6 is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com