Composite ground prepared from anti static, spark failure concrete

A concrete and anti-static technology, applied in the direction of floors, buildings, building structures, etc., to achieve the effect of reasonable structural design, good non-flammability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

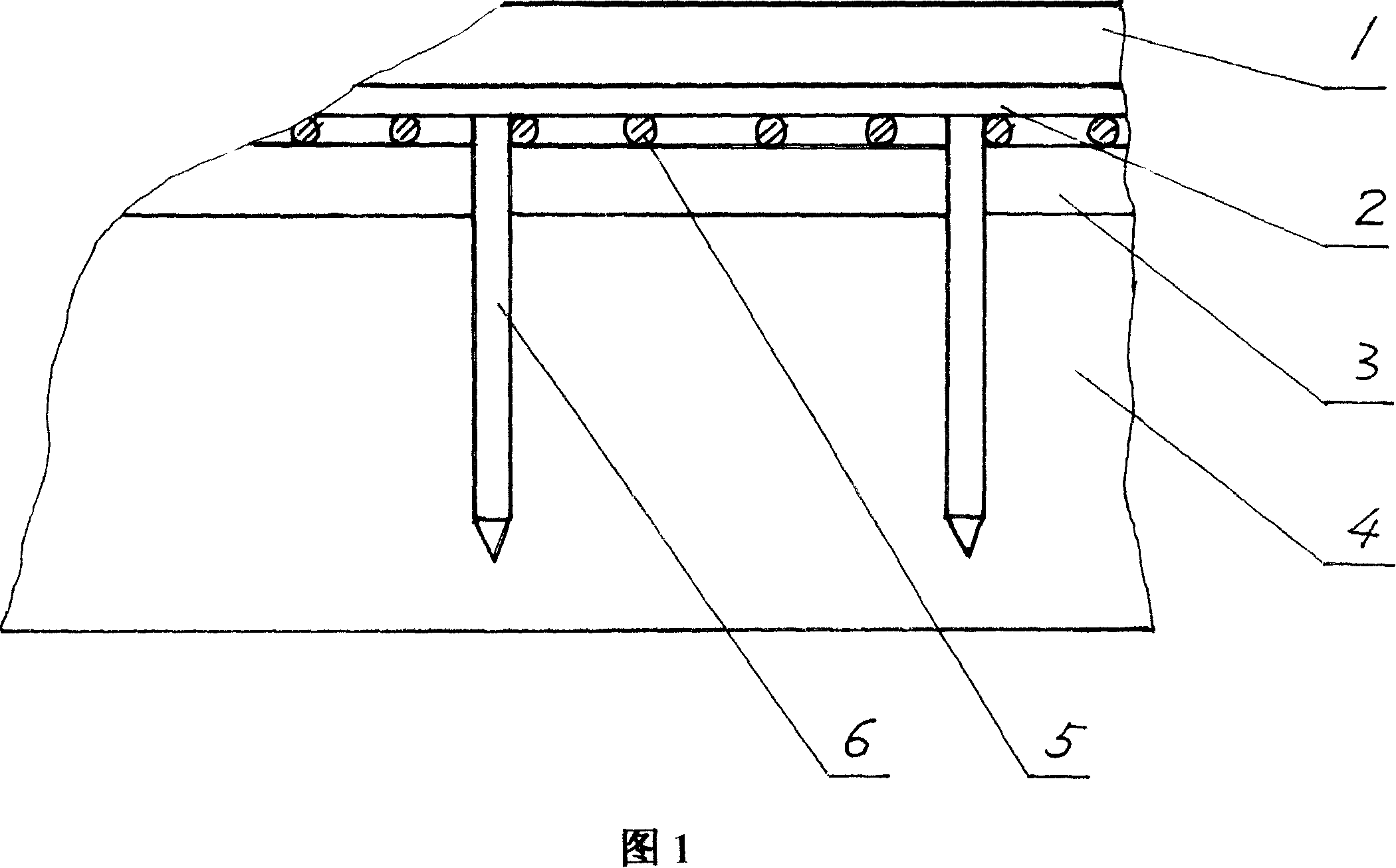

[0010] The specific structure of the present invention will be described in detail according to FIG. 1 . The ground includes a surface layer 1 , a static discharge grid 2 , a grounding metal guide rod 6 and a base layer 4 . Wherein the surface layer 1 is made into a mixture layer of ordinary Portland cement (ordinary Portland cement) with a thickness of 10-30mm and non-flint aggregates and a drag-reducing agent that can reduce the resistivity as required. Between the base layer 4 with the bonding layer 3 and the surface layer 1, a static discharge guide net 2 woven with metal wires 5 is provided, and grounding metal guide rods 6 are arranged at the nodes of the metal wires 5, and each grounding metal guide rod 6 After being connected with wires, they are connected to the common ground electrode (not shown in the figure).

[0011] The construction steps of the concrete composite ground are as follows:

[0012] 1. Treatment of the base layer 4 with the bonding layer 3 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com