Method for preparing propylene by catalytic cracking olefin of containing carbon

A technology of catalytic cracking and carbon olefins, which is applied in the fields of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc., and can solve the problem of low added value of carbon-containing olefin mixtures, low conversion rate of olefin catalytic cracking, and weak combination of olefin catalytic cracking processes and other problems, to achieve good combinability, save energy consumption, and improve the effect of olefin conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

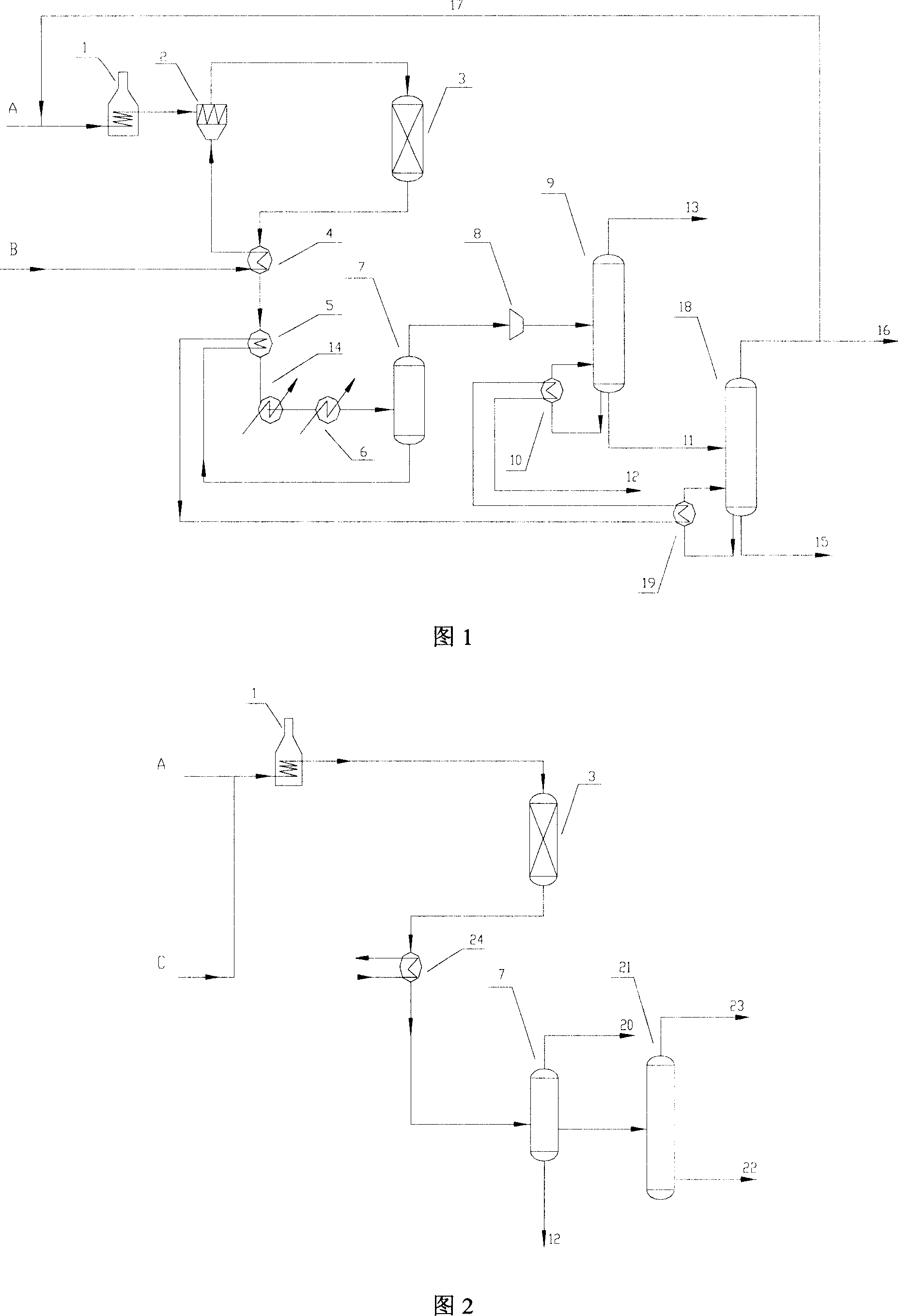

[0030] As shown in Figure 1, the carbon-containing olefin mixture feed composition (weight%) is: butene-1: 45%, butane: 35%, pentene-1: 10%, pentane: 10%. Adopt technological process of the present invention, catalyzer is silicon-aluminum ratio (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the steam to feed weight ratio is 1.5, the reaction temperature is 450°C, the reaction pressure is 0.06MPa, the temperature behind the cooler 6 is 35°C, the cracked product is compressed to 0.8MPa, 88% by weight C 4 Distillate recycle, pilot plant proves that the following proportions of products (% by weight) will be obtained:

[0031] Ethylene: 22.6%

[0032] Propylene: 42.1%

[0033] Other C3 Below: 3.0%

[0034] C 4 Above fraction: 32.3%

Embodiment 2

[0036] As shown in Figure 1, the carbon-containing olefin mixture feed composition is the same as in Example 1, and the process flow of the present invention is adopted, and the catalyst is a ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the steam to feed weight ratio is 2.0, the reaction temperature is 500°C, the reaction pressure is 0.20MPa, the temperature behind the cooler 6 is 55°C, the cracked product is compressed to 0.65MPa, 68% by weight C 4 Distillate recycle, will obtain the product (weight %) of following ratio:

[0037] Ethylene: 20.2%

[0038] Propylene: 45.0%

[0039] Other C 3 Below: 2.8%

[0040] C 4 Above fraction: 32.0%

Embodiment 3

[0042] As shown in Figure 1, the carbon-containing olefin mixture feed composition is the same as in Example 1, and the process flow of the present invention is adopted, and the catalyst is a ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the steam to feed weight ratio is 3.5, the reaction temperature is 550°C, the reaction pressure is 0.3MPa, the temperature after the cooler 6 is 75°C, the cracked product is compressed to 1.0MPa, 48% by weight C 4 Distillate recycle, will obtain the product (weight %) of following ratio:

[0043] Ethylene: 18.8%

[0044] Propylene: 43.3%

[0045] Other C 3 Below: 3.6%

[0046] C 4 Above fraction: 34.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com