Method for preparing olefin in lightweight by catalytic cracking olefin of containing carbon

A technology for catalytic cracking and light olefins, which is applied in the field of catalytic cracking of carbon-containing olefins to produce light olefins. No high-level problems, achieve good combinability, save energy consumption, and improve the conversion rate of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

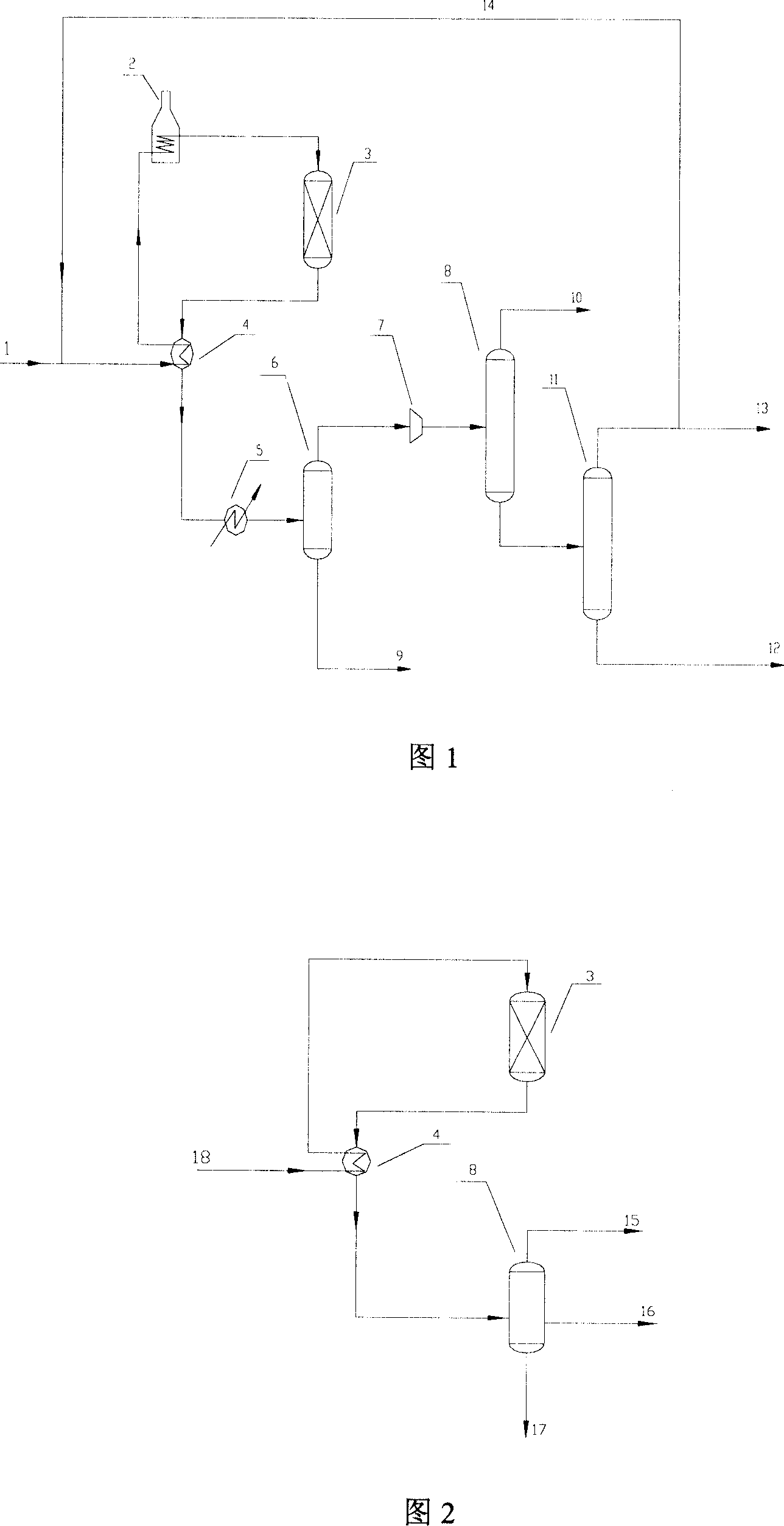

[0032] As shown in Figure 1, the carbon-containing olefin mixture composition (weight %) is: isobutene: 45%, isobutane: 55%. Adopt technological process of the present invention, catalyst is silicon aluminum ratio (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the reaction weight hourly space velocity is 15 hours -1 , the reaction temperature is 450 ° C, the reaction pressure is 0.08 MPa, the temperature after the partial condenser 5 is 25 ° C, the cracked product is compressed to 0.5 MPa, 48% by weight of C 4 Distillate recycle, the pilot plant proves that the following proportions of products (% by weight) will be obtained:

[0033] Ethylene: 20.2%

[0034] Propylene: 43.3%

[0035] Other C 3 Below: 3.2%

[0036] C 4 Above fraction: 33.3%

Embodiment 2

[0038] As shown in Figure 1, the composition of the carbon-containing olefin mixture is the same as in Example 1. Adopt technological process of the present invention, catalyst is silicon aluminum ratio (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the reaction weight hourly space velocity is 60 hours -1 , the reaction temperature is 500 ° C, the reaction pressure is 0.15 MPa, the temperature after the partial condenser 5 is 45 ° C, the cracked product is compressed to 0.85 MPa, 68% by weight of C 4 Distillate recycle, will obtain the product (weight %) of following ratio:

[0039] Ethylene: 21.6%

[0040] Propylene: 44.3%

[0041] Other C 3 Below: 3.0%

[0042] C 4 Above fraction: 31.1%

Embodiment 3

[0044] As shown in Figure 1, the composition of the carbon-containing olefin mixture is the same as in Example 1. Adopt technological process of the present invention, catalyst is silicon aluminum ratio (SiO 2 / Al 2 o 3 ) 200 ZSM-5 molecular sieve, the reaction weight hourly space velocity is 100 hours -1 , the reaction temperature is 550°C, the reaction pressure is 0.30MPa, the temperature after the partial condenser 5 is 55°C, the cracked product is compressed to 0.65MPa, 88% by weight of C 4 Distillate recycle, will obtain the product (weight %) of following ratio:

[0045] Ethylene: 23.5%

[0046] Propylene: 45.3%

[0047] Other C 3 Below: 3.5%

[0048] C 4 Above fraction: 27.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com