New type electric impact drill

An impact electric drill, a new type of technology, applied in the direction of portable impact tools, impact tools, portable drilling rigs, etc., can solve the problems of unstable EMC anti-interference effect of impact electric drills, unreasonable structure, shortened service life of bearings, etc., to ensure anti-interference effect , improve the service life and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

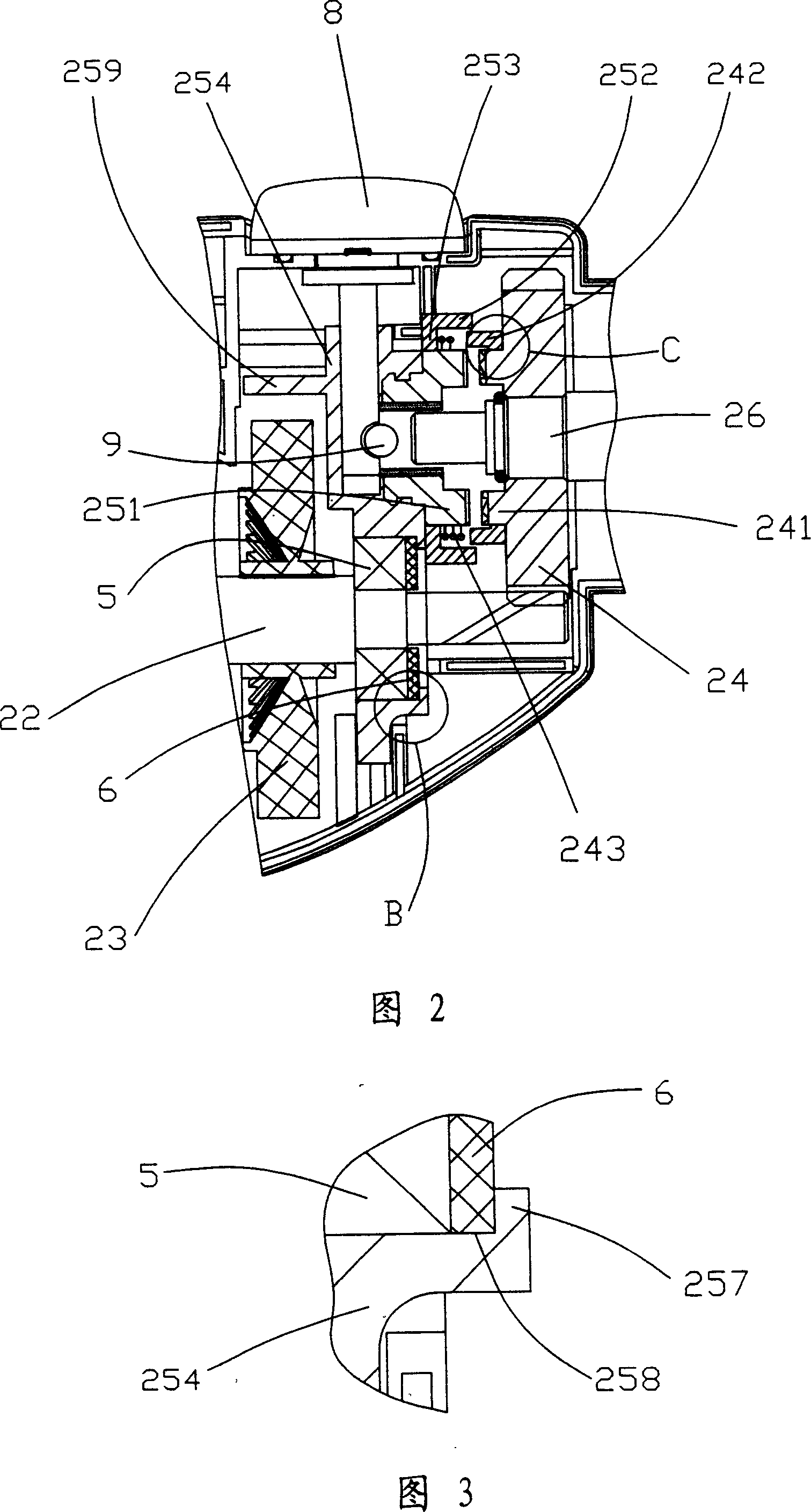

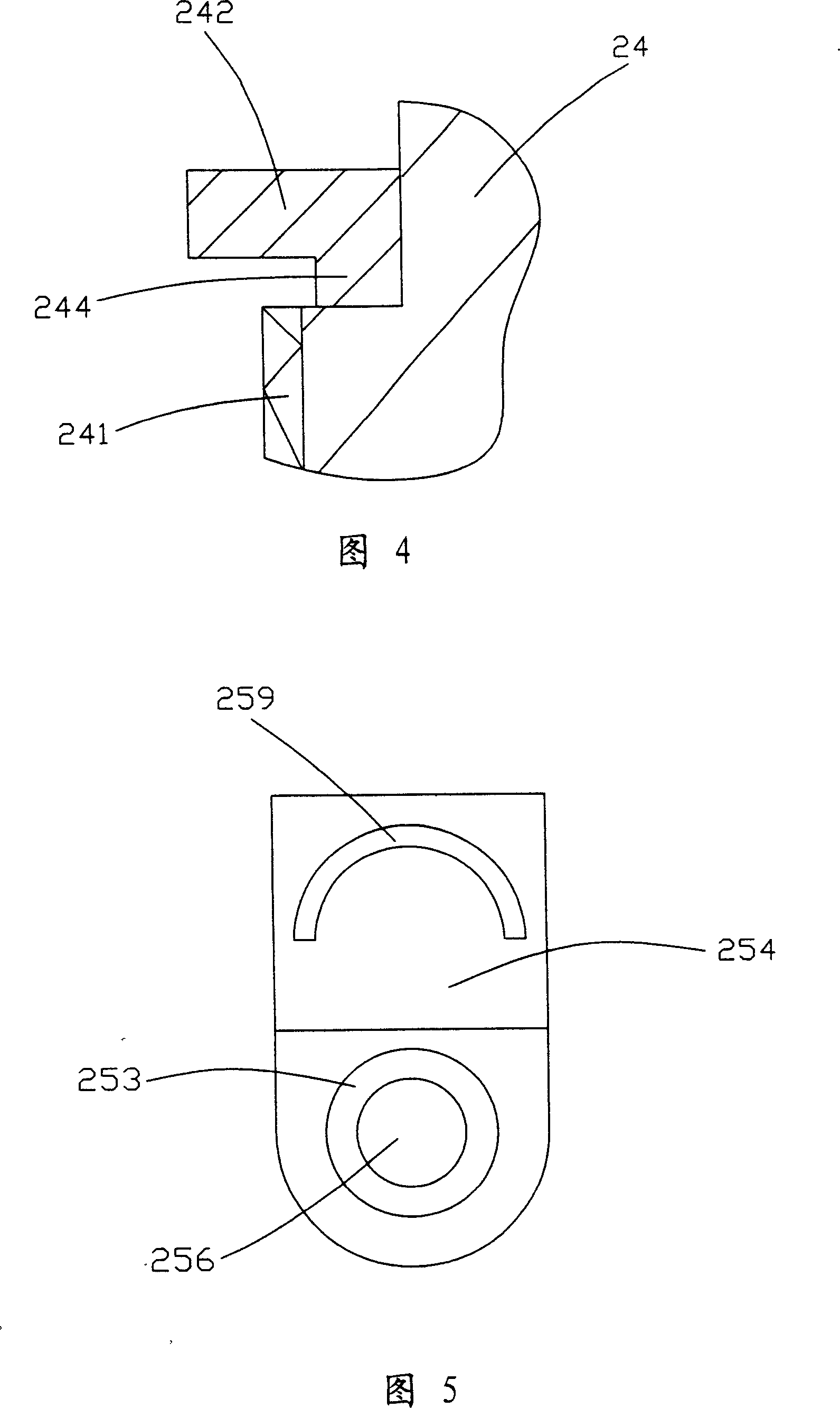

[0033] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the percussion electric drill provided according to the present invention includes a handle 1, a body 2 and a drill chuck 3, and a switch assembly 11 is installed at the handle portion; The motor 21 controlled by 11, the motor shaft 22 driven by the motor 21, the cooling device 23 installed at the output end of the motor shaft 22, the transmission gear 24 meshed with the end of the motor shaft 22, the impact device between the cooling device 23 and the transmission gear 24 25, the output shaft 26 fixed on the transmission gear 24; the drill chuck 3 is installed on the end of the output shaft 26 protruding from the body 2. The inner surface of the transmission gear 24 is provided with a first impact tooth 241, and the corresponding part of the impact device 25 is provided with a second impact tooth 251 that cooperates with it; the outer circumference of the first impact tooth 241 is provided with a first annular peripheral w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com