Test centre for performance of vehicle wind screen wiper assembly

A car windshield and glass scraping technology, which is applied to the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of tediousness, high labor intensity, and low degree of automation, so as to ensure detection accuracy, reduce labor intensity, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

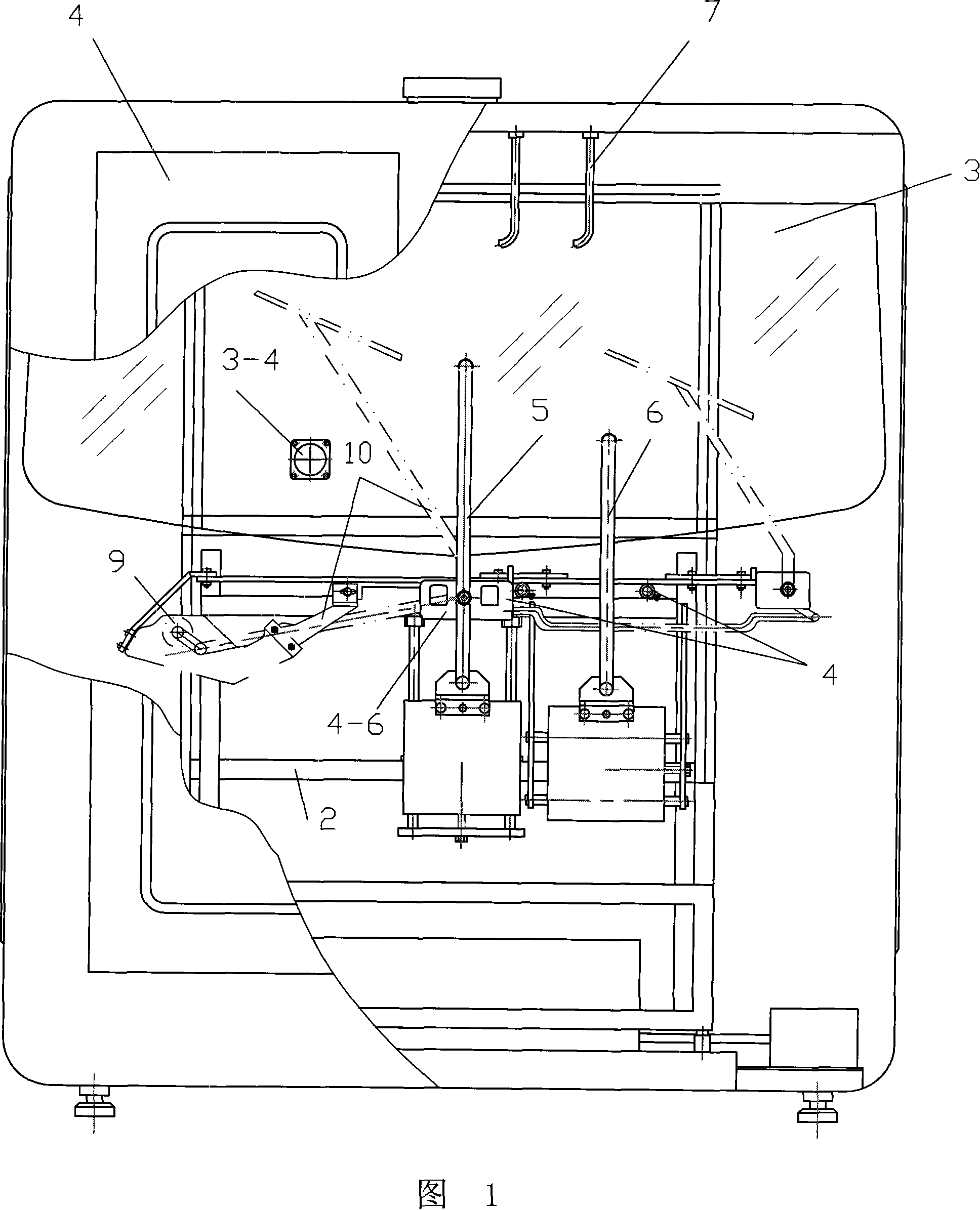

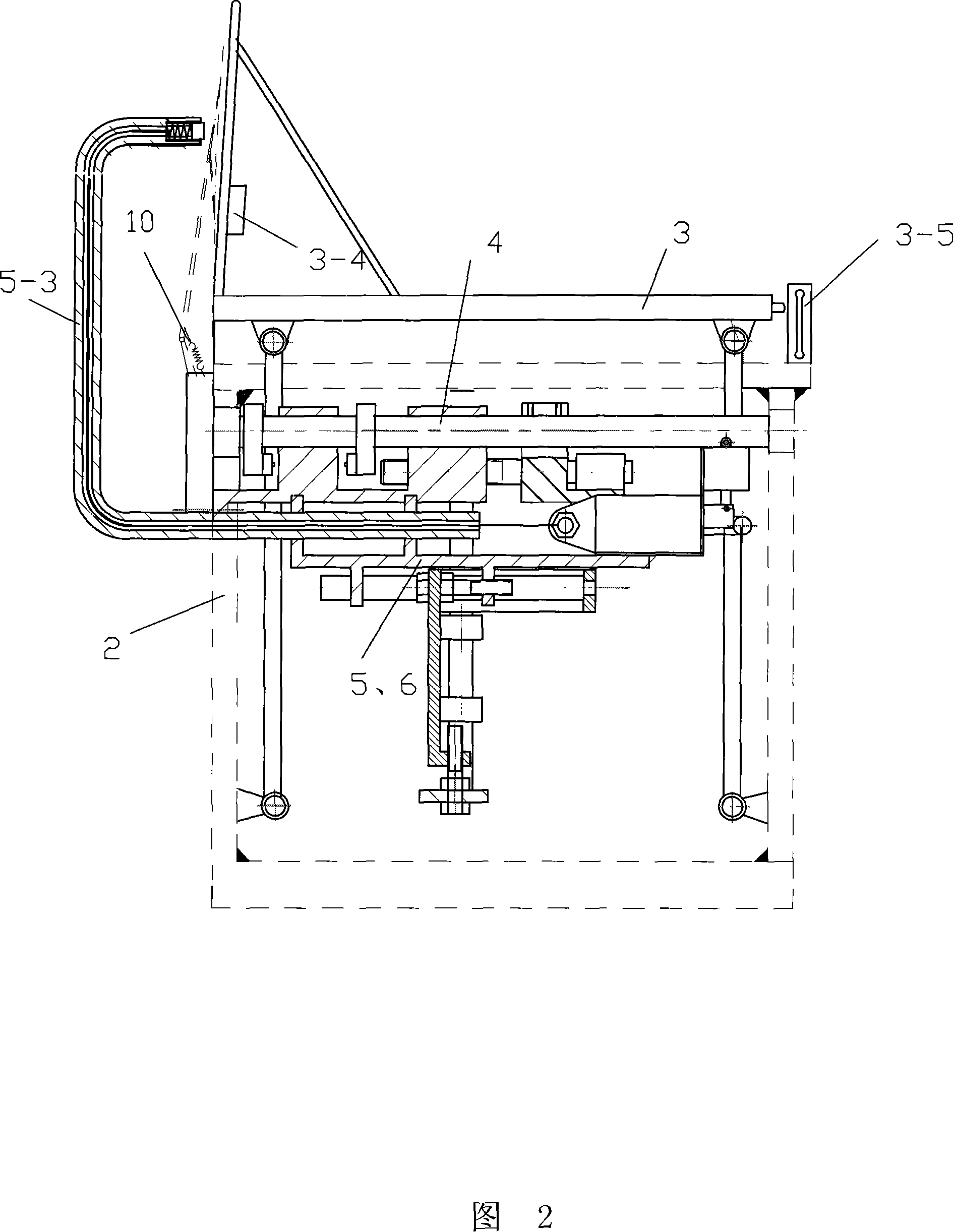

[0041] See Fig. 1 and Fig. 2, a kind of automobile windshield wiper assembly performance test center, it comprises test compartment 1, the pressure transmission device 3 that is placed on the frame 2 in test compartment 1, the pressing force adjustment device 4 , the left wiper brake device 5, the right wiper brake device 6 and the rain device 7 for creating a rainy environment, the electrical control device 8 is placed in an independent electrical control cabinet, including the wiper assembly 9 and the wiper The water motor 10 is the object to be tested, and it is installed on the installation template 4-6 of the pressing force adjustment device 4; the displacement counting sensor 3-4 for testing the stop angle and wiper frequency of the wiper assembly is closely attached to the window. Behind the glass 3-2, the pressure sensor 3-5 for detecting the pressing force of the wiper on the window glass is fixed on the frame 2 behind the window glass frame 3-1;

[0042] See Fig. 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com