Method for vacuum prification of material by self-rotation elevation tracked solar furnace

A vacuum and sunlight technology, applied in solar thermal devices, solar thermal power generation, furnaces, etc., can solve the problems of large light spot, large diameter of the second condenser, affecting the purification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

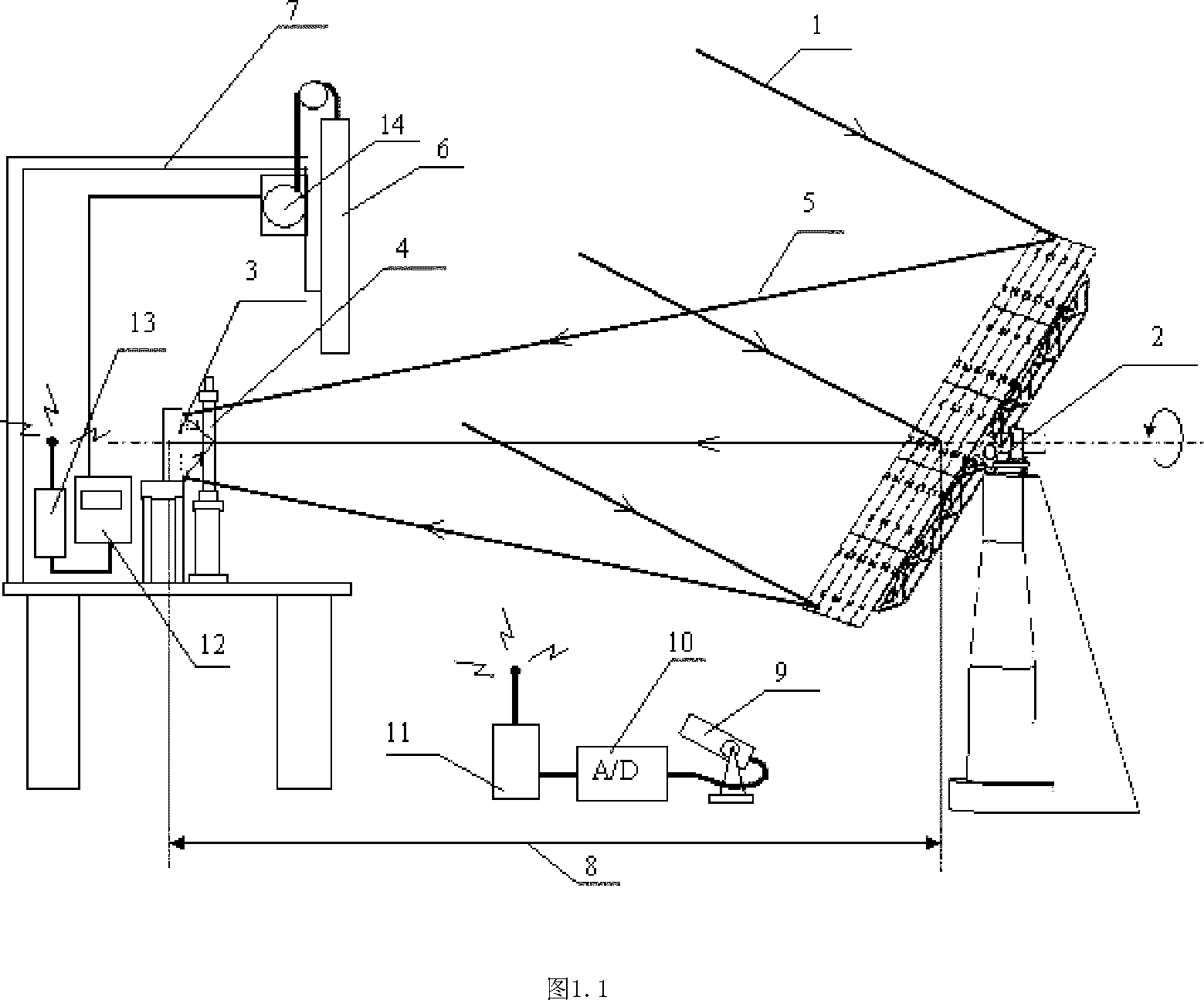

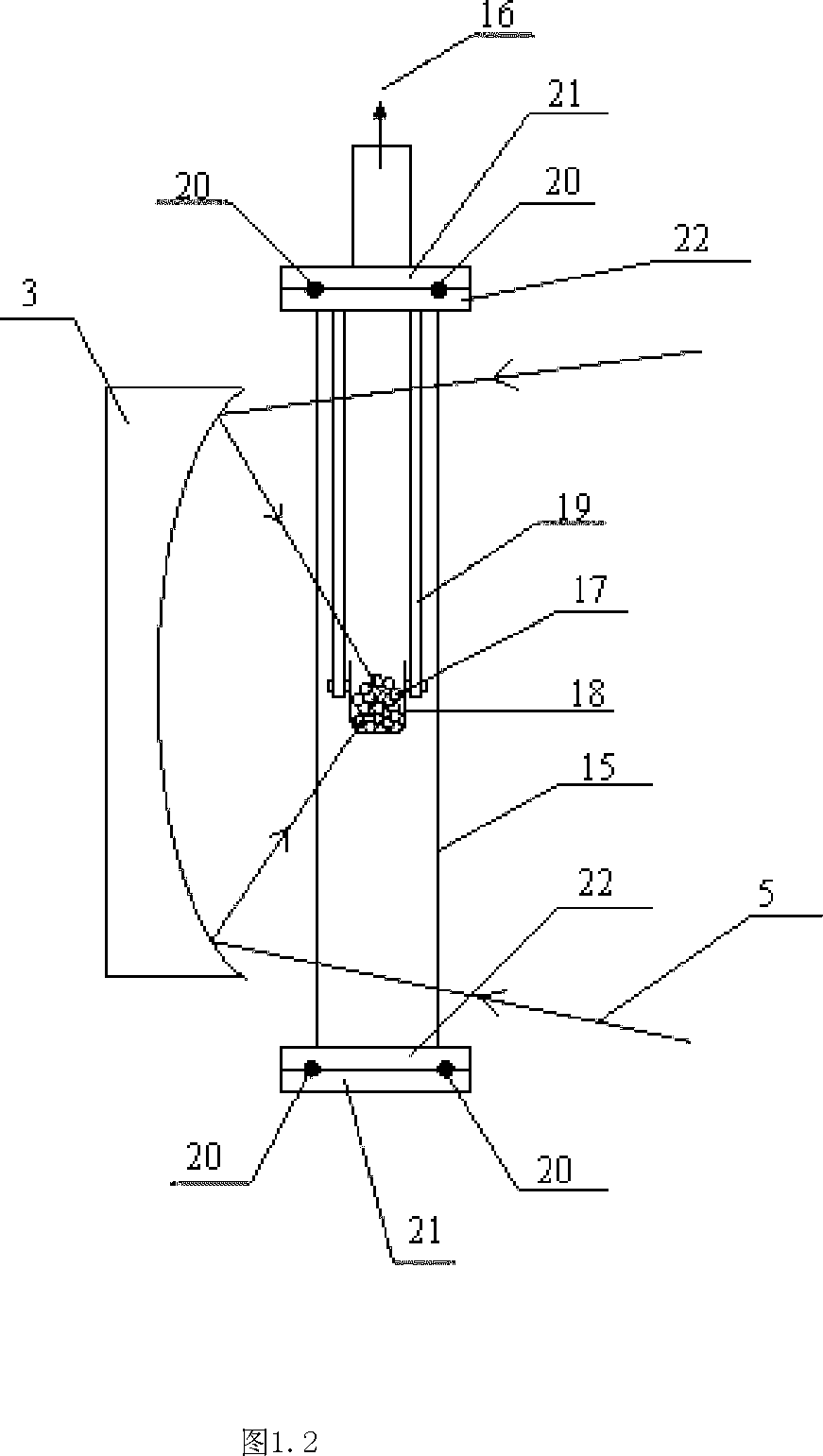

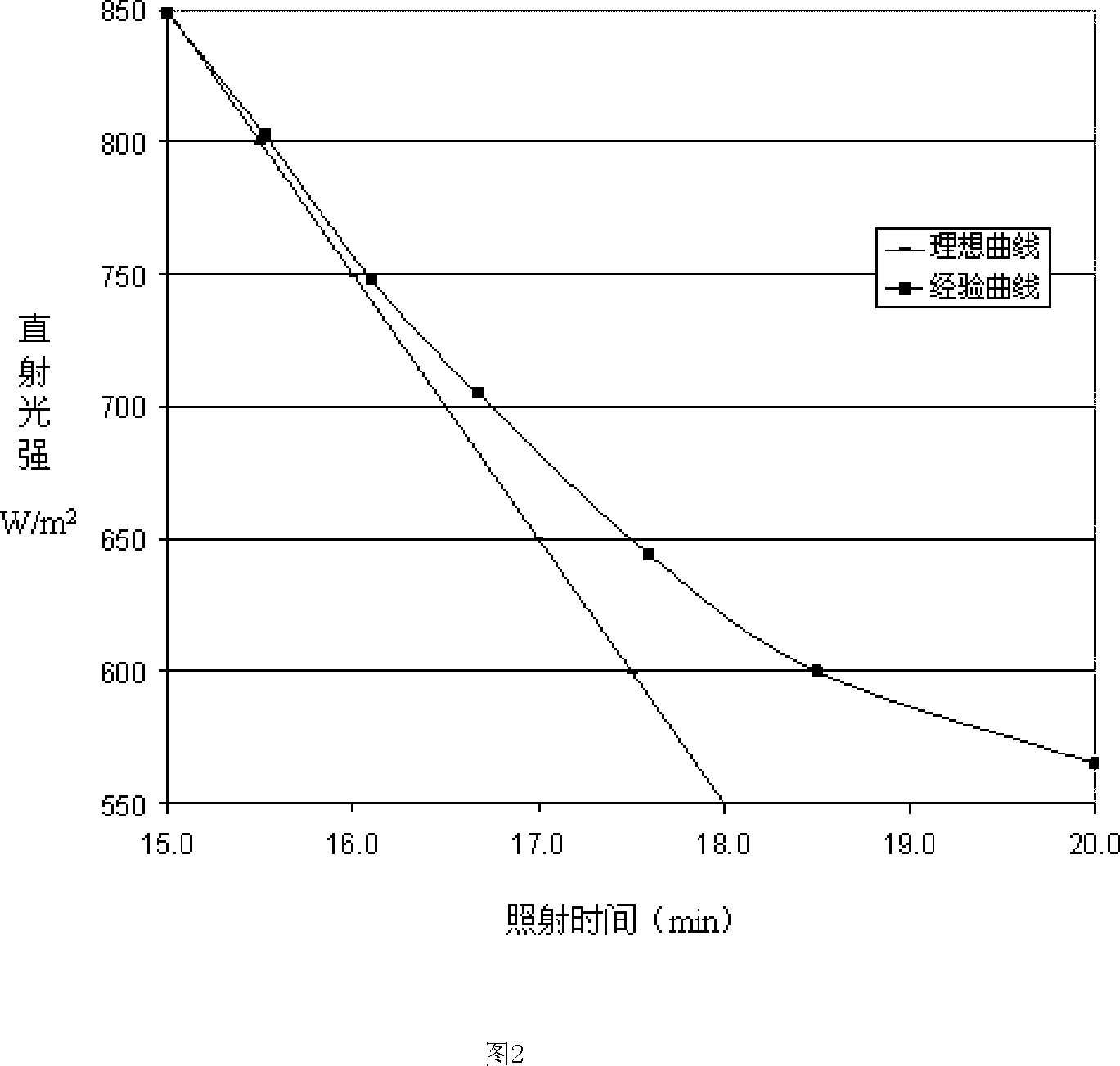

[0020] This scheme is an application example of the present invention. The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: the principle structure diagram of the present invention is provided by Fig. 1.1 and 1.2, and the selection of the irradiation time relevant to sunlight irradiation is provided by Fig. 2. Among them, the heliostat 2, which is tracked by the spin elevation angle, tracks the sun, and the lighting area of the heliostat is 25m 2 , the target distance 8 of the heliostat is 18m, the heliostat reflects the incident sunlight 1 and focuses it to the spherical reflector 3 placed in the studio 7 at the same time, the diameter of the reflector is 60cm; the spherical reflector 3 will come from the heliostat The light 5 of the mirror is re-focused, and its focal point is at the center of the high-purity quartz crucible 18. The capacity of the crucible i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com