Technological process of treating papermaking effluent for reuse based on membrane integrating technique

A process method and technical treatment technology, applied in the field of wastewater treatment of environmental protection, can solve the problems of poor removal of other substances, no comprehensive wastewater report, difficulty in regeneration of activated carbon, etc., so as to promote healthy and sustainable development and improve water quality. Resource utilization rate and the effect of reducing comprehensive water consumption per ton of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

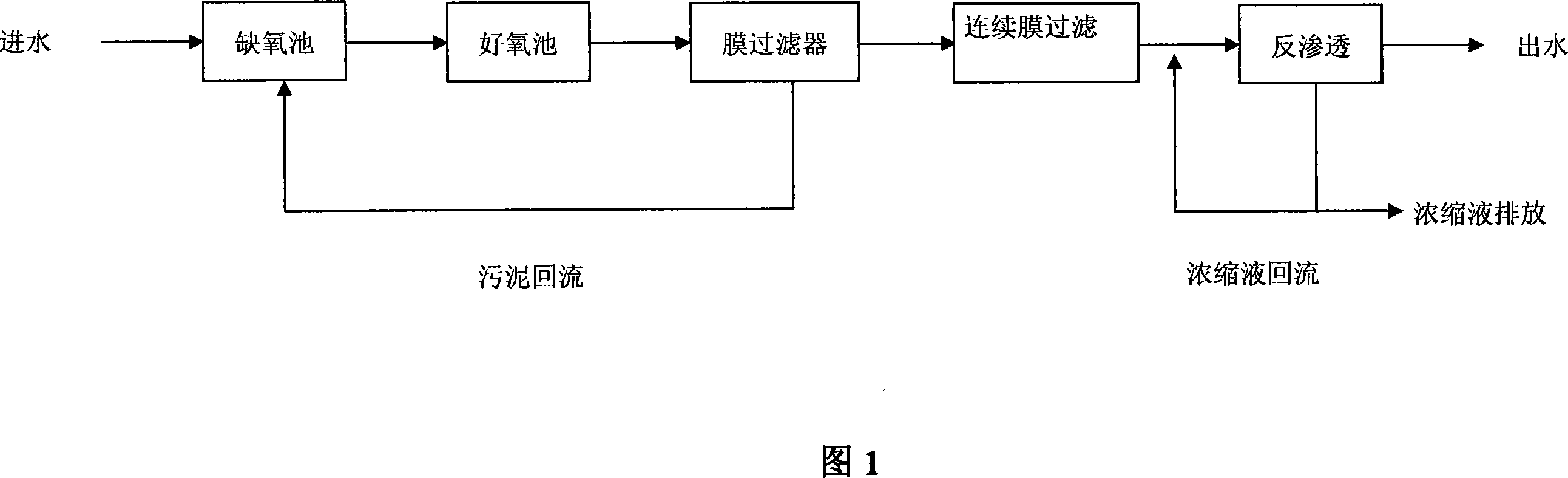

Method used

Image

Examples

Embodiment 1

[0051] A paper mill in the south uses commercial wood and recycled waste paper as raw materials, and the quality of wastewater: COD cr 1500~3500mg / l, SS 1400~3000mg / l, pH6~9. After going through the mixing tank, coagulation, cooling and initial precipitation, the water enters the integrated membrane system with a treatment capacity of 2m 3 / h.

[0052] The MBR membrane module used is a 6-inch submerged columnar polyethersulfone hollow fiber membrane module, and the filtration accuracy of the membrane is 0.1 micron. The CMF membrane module is an industrial-scale internal pressure polyethersulfone hollow fiber membrane module with a diameter of 6 inches. The filtration accuracy of the membrane is 0.01 micron, and the filtration mode is full filtration. The RO membrane module is a commercially available 8-inch pollution-resistant roll-type reverse osmosis membrane module.

[0053] The operating conditions of the MBR: one operating cycle is 8 minutes, the water production is st...

Embodiment 2

[0058] The water quality and treatment capacity of waste water are identical with example 1.

[0059] The MBR membrane module used is a 6-inch submerged columnar polyvinylidene fluoride hollow fiber membrane module, and the filtration accuracy of the membrane is 0.05 micron. CMF membrane module and RO membrane module are the same as Example 1.

[0060] The operating conditions of the MBR: one operating cycle is 10 minutes, the water production is stopped for 2 minutes, and the backwash is 30 seconds. The backwash water is the water produced by the membrane bioreactor. MBR biochemical process conditions: activated sludge concentration (MLSS) 8500mg / l, sludge age 60 days. The hydraulic retention time in the anoxic section is 1.5 hours, and the dissolved oxygen (DO) concentration is 0.15 mg / L; the hydraulic retention time in the aerobic section is 20 hours, the gas-water ratio is 15:1, and the DO in the aerobic section is maintained at 3.5 mg / L; Maintain a certain aeration inte...

Embodiment 3

[0065] The water quality of waste water and waste water treatment capacity are identical with example 1.

[0066] The MBR membrane module used is a 6-inch submerged columnar polyvinyl chloride hollow fiber membrane module, and the filtration accuracy of the membrane is 0.15 microns. CMF membrane module and RO membrane module are the same as Example 1.

[0067] The operating conditions of the MBR: one operating cycle is 15 minutes, the water production is stopped for 2 minutes, and the backwash is 30 seconds. The backwash water is the water produced by the membrane bioreactor. MBR biochemical process conditions: activated sludge concentration (MLSS) 4800mg / l, sludge age 30 days. The hydraulic retention time in the anoxic section is 2.5 hours, and the dissolved oxygen (DO) concentration is 0.3mg / L; the hydraulic retention time in the aerobic section is 18 hours, the gas-water ratio is 15:1, and the DO in the aerobic section is maintained at 3.0mg / L; Maintain a certain aeration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com