Grinder dresser with linerarly arranged diamond strips

A grinding wheel dresser, linear arrangement technology, applied in metal processing equipment, abrasive surface adjustment devices, parts of grinding machine tools, etc. Durable, low cost, low tool cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

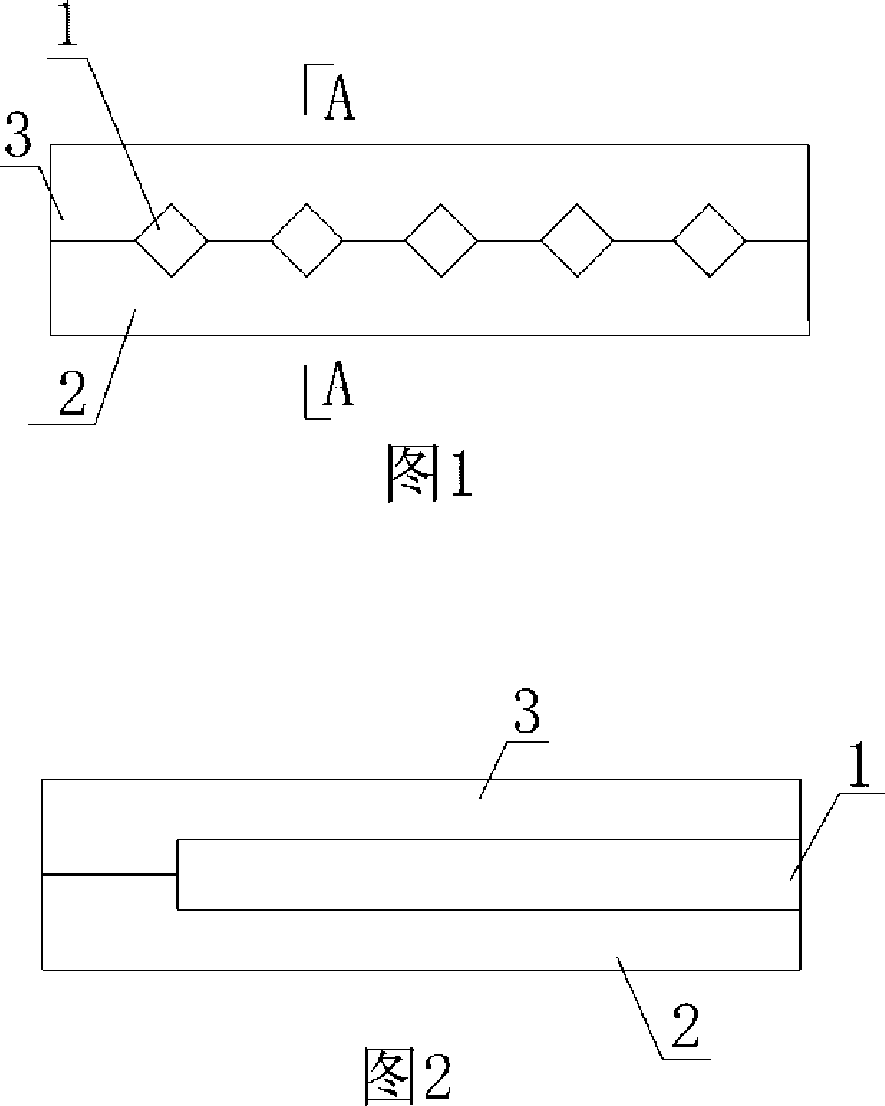

[0031] Referring to Figures 1 and 2, Embodiment 1 is a single-row diamond strip linear arrangement grinding wheel dresser, which is formed by connecting the cutter body and the die, and the artificial diamond strips in the die are uniformly arranged in a single row in the alloy sintered body. Arrangement, the cross-section of the synthetic diamond strip 1 is diamond-shaped, and the lower edges of a row of synthetic diamond strips are evenly embedded in a row of parallel V-shaped grooves on the metal support 2, and the synthetic diamond strips are outside the V-shaped grooves of the metal support. The part is integrated with the alloy sintered body 3 formed by sintering the metal powder alloy.

[0032] There are 2 to 20 synthetic diamond strips in each row, and the distance between two synthetic diamond strips in each row, the distance between two layers of synthetic diamond strips, and the length, width and height of each synthetic diamond strip can be designed and adjusted acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com