Rolling-sliding elements and process for production of the same

A technology of sliding parts and parts, which is applied in the direction of anti-centrifugal rotating parts, mechanical equipment, manufacturing tools, etc., can solve the problems of not getting rolling life, not specifically disclosing the number, size distribution state, increasing Cr content, etc., to achieve Effects of improving life, suppressing coarsening, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~18

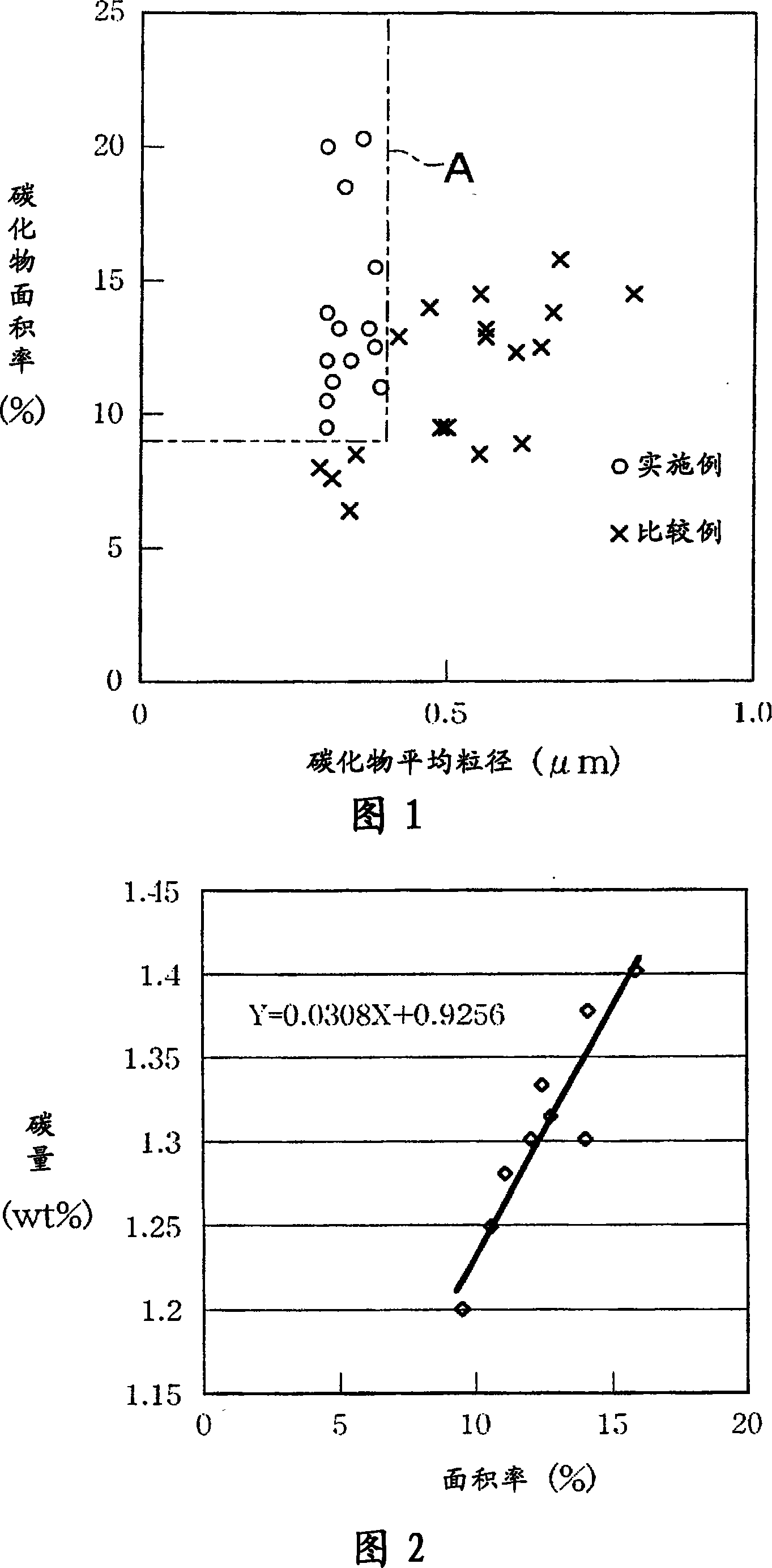

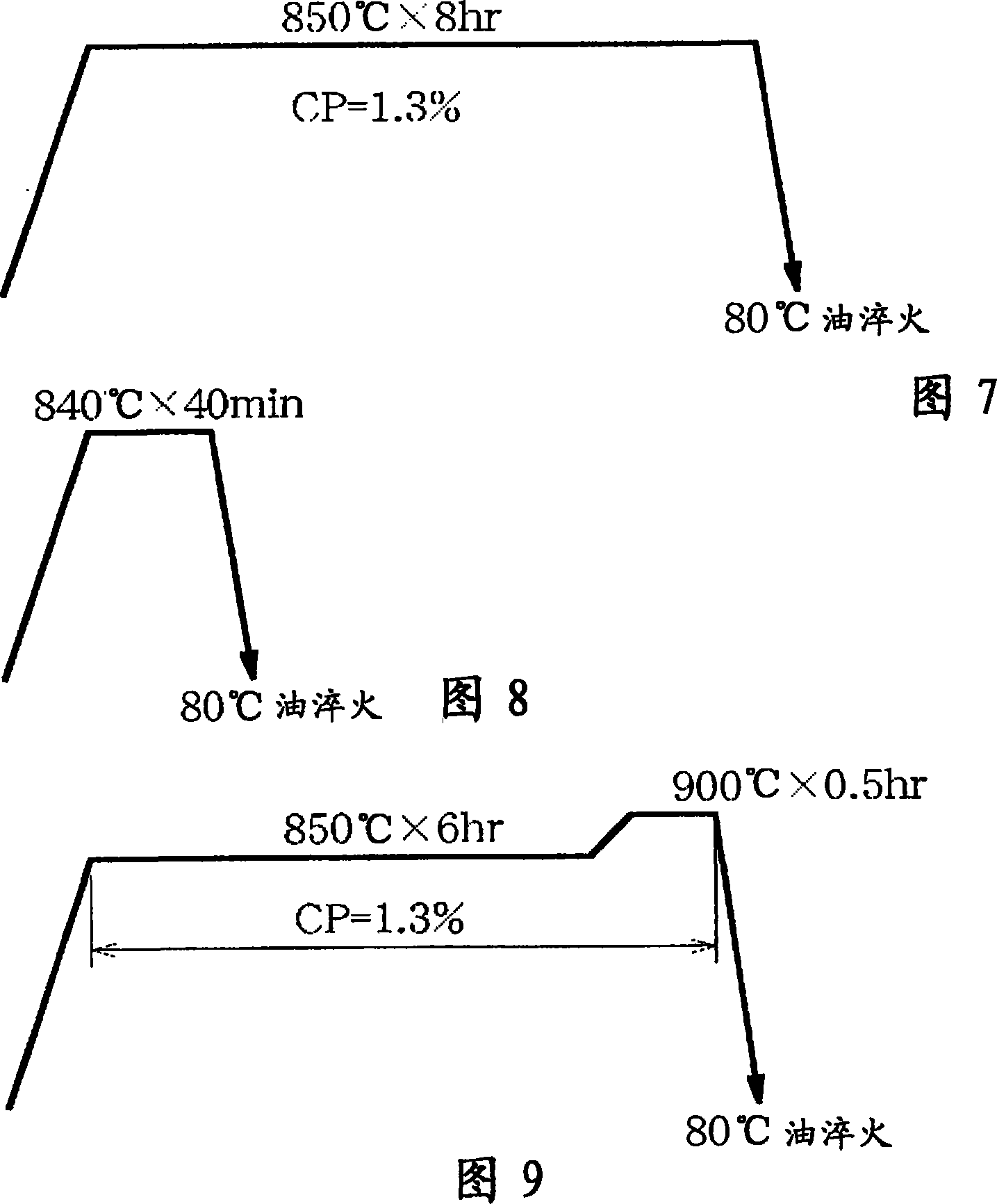

[0087] Prepare 17 steel materials with the composition shown in Table 1. As mentioned above, in order to obtain excellent workability and high hardness after carburization, it is necessary to be in a state where a large amount of carbides are precipitated before carburization. After spheroidizing annealing treatment, 28 kinds of inner ring blanks used in rolling bearings of model 6206 were formed, and the inner ring blanks were heat-treated under the conditions shown in Figs. 3-9 to prepare inner rings (Examples 1-10 and comparison Examples 1-18). It should be noted that, in order to measure the number of precipitated carbides before the carburizing treatment after the spheroidizing annealing, the test piece before the carburizing treatment was observed with a scanning electron microscope magnification of 10,000 times to measure the number.

[0088] [Table 1]

[0089]

Steel type

Composition (wt%)

C

Si

Mn

P

S

Cr

Mo

V

Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com