Floatation and ink removing machine

A deinking machine and flotation technology, applied in the field of papermaking machinery, can solve the problems of reduced pulp quality, increased operating costs, large driving force, etc., and achieve the effect of high pulp quality and thorough deinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

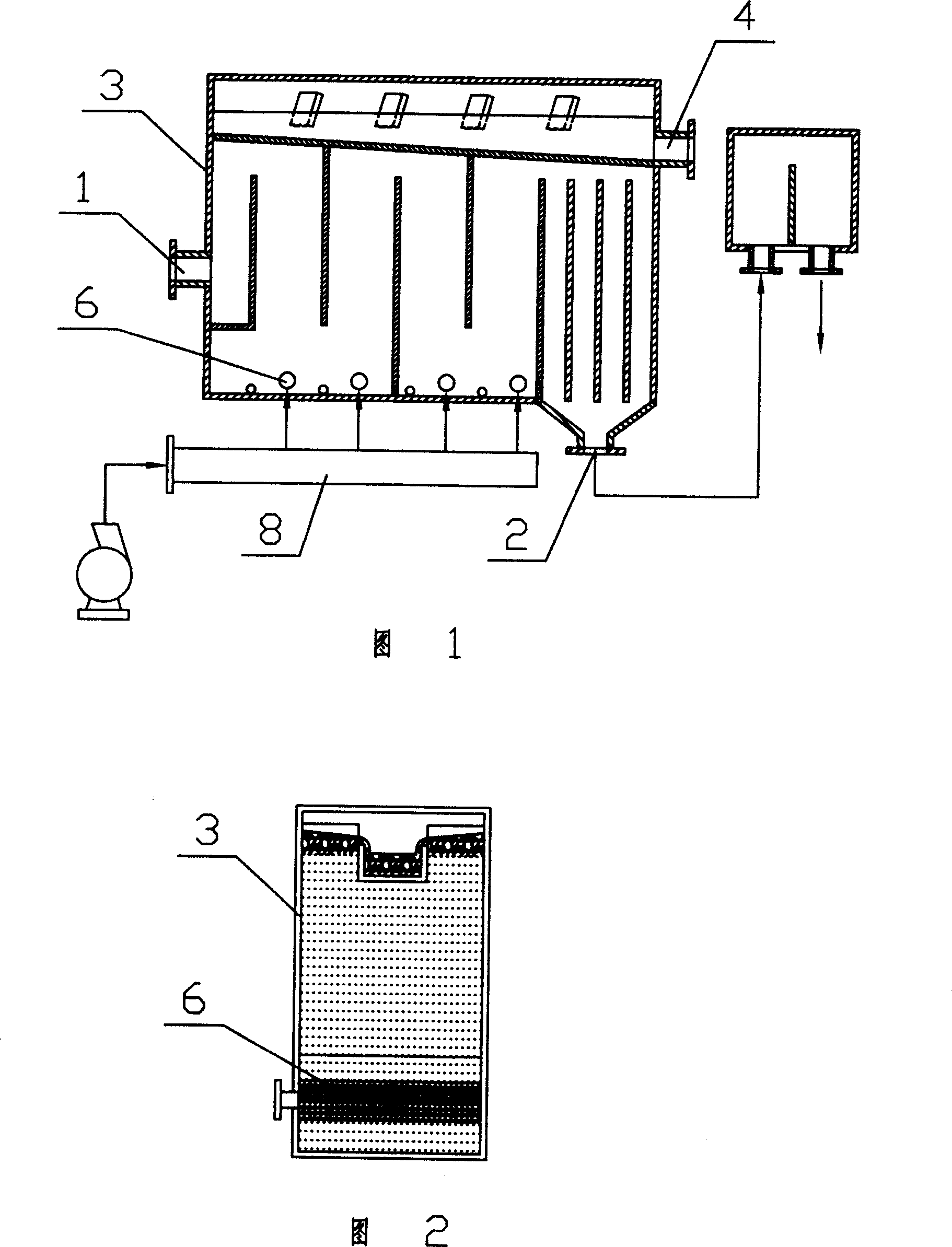

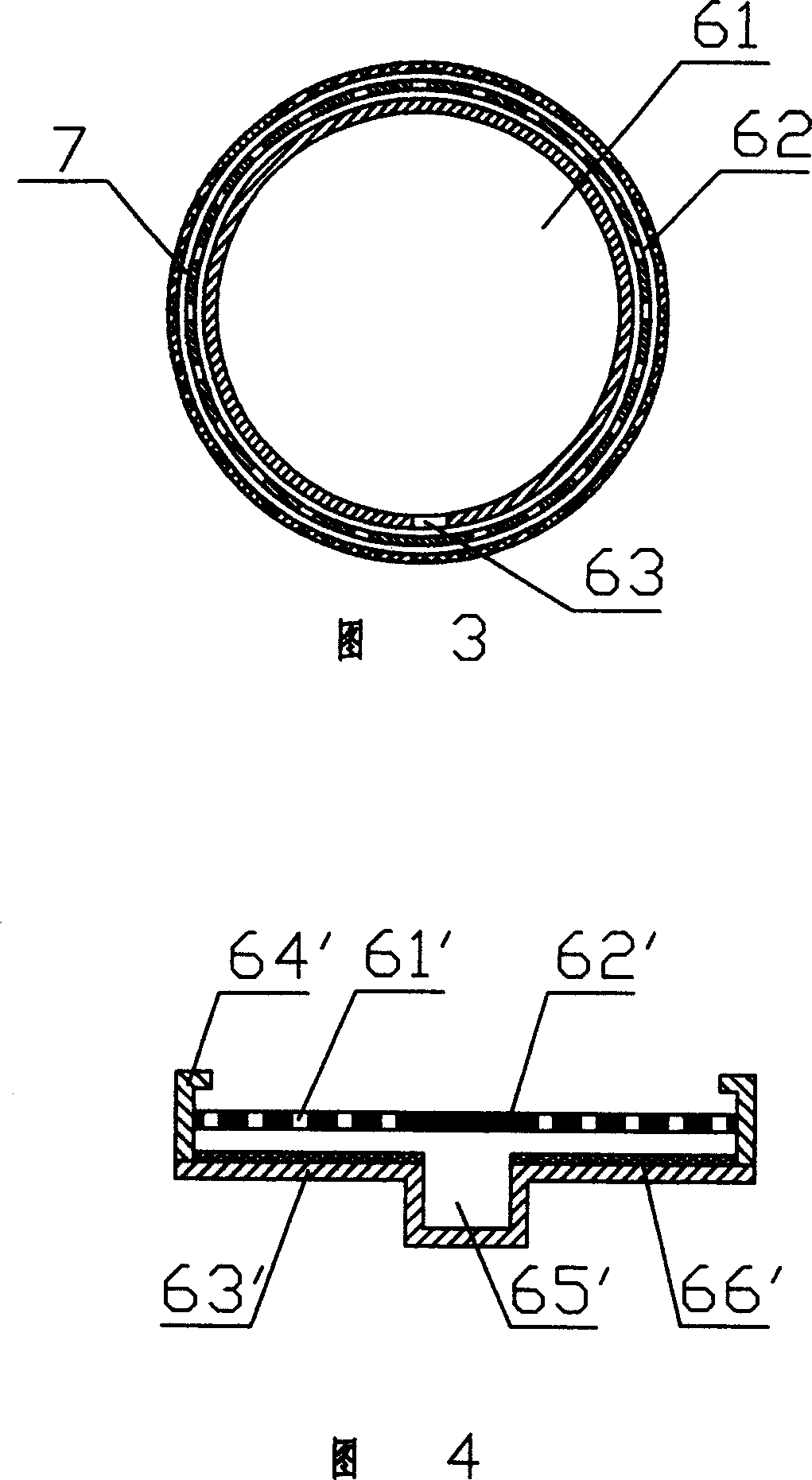

[0022] Embodiment 1: As shown in Figure 1, Figure 2, and Figure 3, the flotation deinking machine includes a deinking machine housing 3, a liquid inlet 1 provided on one side of the deinking machine housing 3 and The liquid outlet 2 on the other side of the bottom of the machine housing 3, the ink collecting device located on the upper part of the cavity of the deinking machine housing 3 and the slag outlet 4 connected with the ink collecting device, the deinking machine housing 3 A number of microporous aeration devices 6 that can send flotation bubbles to the liquid in the deinking machine housing are installed at the bottom of the cavity, and an air inlet pipe 8 connected to the microporous aeration device 6, the plurality of microporous aeration devices 6 is equipped with air holes that can generate bubbles of different diameters.

[0023] In this embodiment, the diameters of the air holes of the single microporous aeration device 6 are the same, that is, each microporous aera...

Embodiment 2

[0026] Embodiment 2: As shown in Fig. 1, Fig. 2 and Fig. 4, this embodiment is basically the same as the first embodiment, and the difference lies in the structure of the microporous aeration device 6.

[0027] In FIG. 4, the microporous aeration device 6 includes an air distribution plate 62' provided with a plurality of air outlet pores 61', and a bottom plate 63 located under the air distribution plate 62' and capable of blocking the air outlet pores 61' of the air distribution plate ', the bottom plate 63' is provided with an air distribution plate movement limiting device 64', the bottom plate is also provided with a recessed air inlet groove 65', and the corresponding air distribution plate above the air inlet groove 65' does not Equipped with air outlet holes. A sealing rubber gasket 66' is provided between the air distribution plate 62' and the bottom plate 63'; the sealing rubber gasket 66' is fixed on the bottom plate 63'. The working principle is: when not working, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com