Multiple-temperature area heating body and method for manufacturing same

A manufacturing method and technology of heating body, which are applied in chemical instruments and methods, crystal growth, post-processing, etc., can solve the problems of affecting the stability of the temperature field, increasing the cost of equipment and difficulty of control, and simplifying the operation and maintaining the temperature field. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

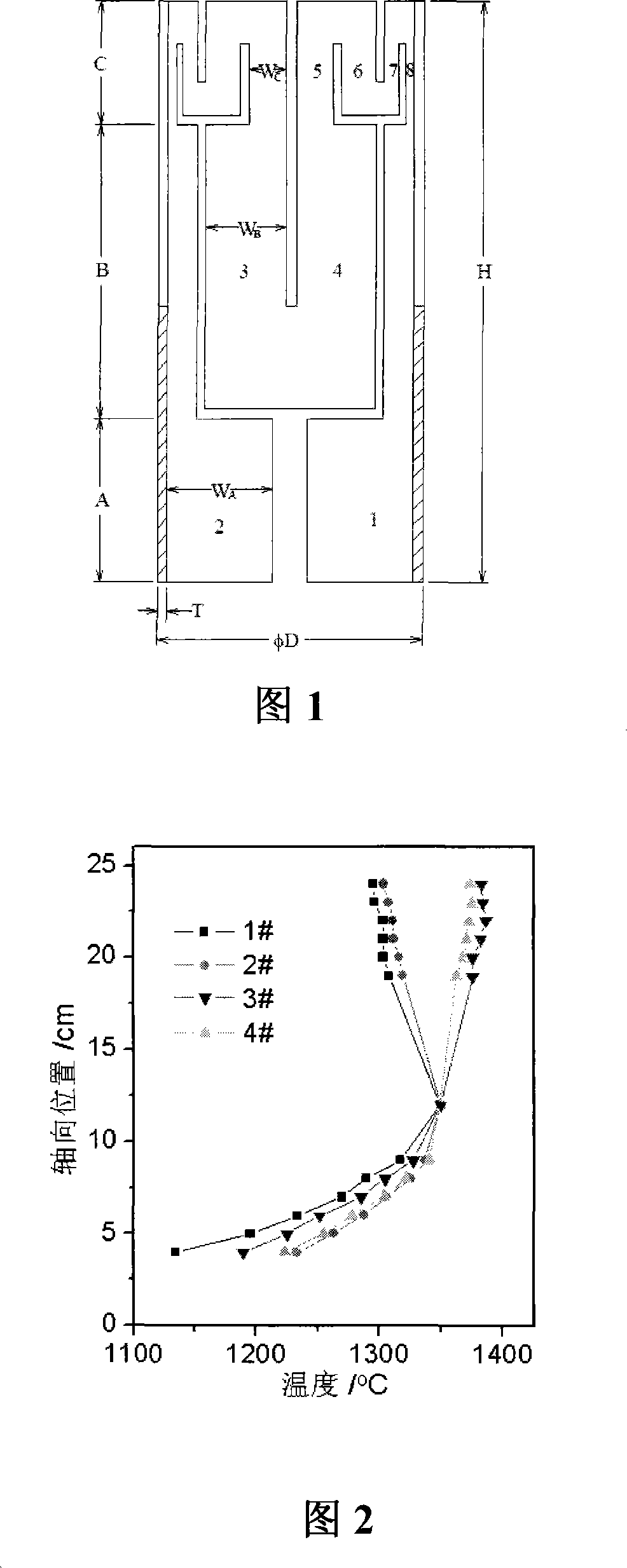

[0034] A high-purity graphite resistance heating material is used to make a cylinder with an outer diameter of D=119mm, a wall thickness of T=4.5mm, and a height of H=260mm. According to the present invention, the heating element is grooved, wherein: H A =45mm, H B =215mm, H C =0; W A =45mm, W B =43mm, W C =0mm. Place the heating element in the temperature gradient crystal growth furnace, close the furnace, vacuum, fill with high-purity argon gas and raise the temperature, and measure the temperature distribution of the crystal growth zone, as shown in Figure 2 on line 1#.

Embodiment 2

[0036] A high-purity graphite resistance heating material is used to make a cylinder with an outer diameter of D=119mm, a wall thickness of T=4.5mm, and a height of H=260mm. According to the present invention, the heating element is grooved, wherein: H A =115mm, H B =145mm, H C =0; W A =45mm, W B =43mm, W C =0mm. Place the heating element in a temperature gradient crystal growth furnace, close the furnace, vacuum, fill with high-purity argon gas and raise the temperature, and measure the temperature distribution of the crystal growth zone, as shown in Figure 2 on line 2#.

Embodiment 3

[0038] A high-purity graphite resistance heating material is used to make a cylinder with an outer diameter of D=119mm, a wall thickness of T=4.5mm, and a height of H=260mm. According to the present invention, the heating element is grooved, wherein: H A =45mm, H B =180mm, H C =35mm; W A =45mm, W B =43mm, W C = 20mm. Place the heating element in a temperature ladder crystal growth furnace, close the furnace, vacuum, fill with high-purity argon gas and raise the temperature, and measure the temperature distribution of the crystal growth zone, as shown in Figure 2 on line 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com