Cell suspension culture tank

A cell culture and cell reaction technology, applied in the field of cell culture tanks, can solve problems such as expensive and achieve the effect of extending the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the research of 150ml wide body flat conical bottom cell reactor

[0046] The fed-batch culture of CHO-producing cell lines in small shake flasks is an important way to screen solid and high-yield producing cell lines. In this study, the results (Table 1) using a 150ml wide-bodied flat conical bottom cell reactor (Figure 2) and a wide-bodied conical bottom shake flask (Corning Company #431123) showed that the 150ml shake flask is suitable for small-scale Fed-batch study, the inoculation volume is small (only 1 / 20 of the working volume). The expression titer can be compared with a 2L reactor. Inverted flat conical shake flasks obviously have cell sedimentation, especially those cell clusters are more likely to settle, mainly because the mixing of the pointed bottom is not good. For this reason, we gave up using the inverted conical bottom and adopted Inverted flat cone bottom.

[0047] Table 1: The culture tank is placed on the shaker platform with a rot...

Embodiment 2

[0050] Embodiment 2: Research on conical bottom tanks with different cone angles

[0051] Plastic centrifuge tubes with different cone angles were used on a shaker to study the effect of cone angle on shaking, medium mixing and inoculum volume (Table 2). If the cone angle is not too wide or too narrow, shaking cannot cause the culture volume to spread to the tank wall to form a wider thin layer to expand the surface of the medium. For example, if the cone angle is too wide, such as when it is greater than 70 degrees, it has no obvious difference from the flat-bottomed tank. If the cone angle is too small, such as when it is less than 30 degrees, it has no obvious difference from the flat-bottomed tank. The results of Table 3 It was shown that a cone angle of 30 degrees was the minimum angle for effective shaking and mixing. According to calculations, tanks with cone angles greater than 70 degrees did not significantly reduce the inoculum volume compared with conventional round...

Embodiment 3

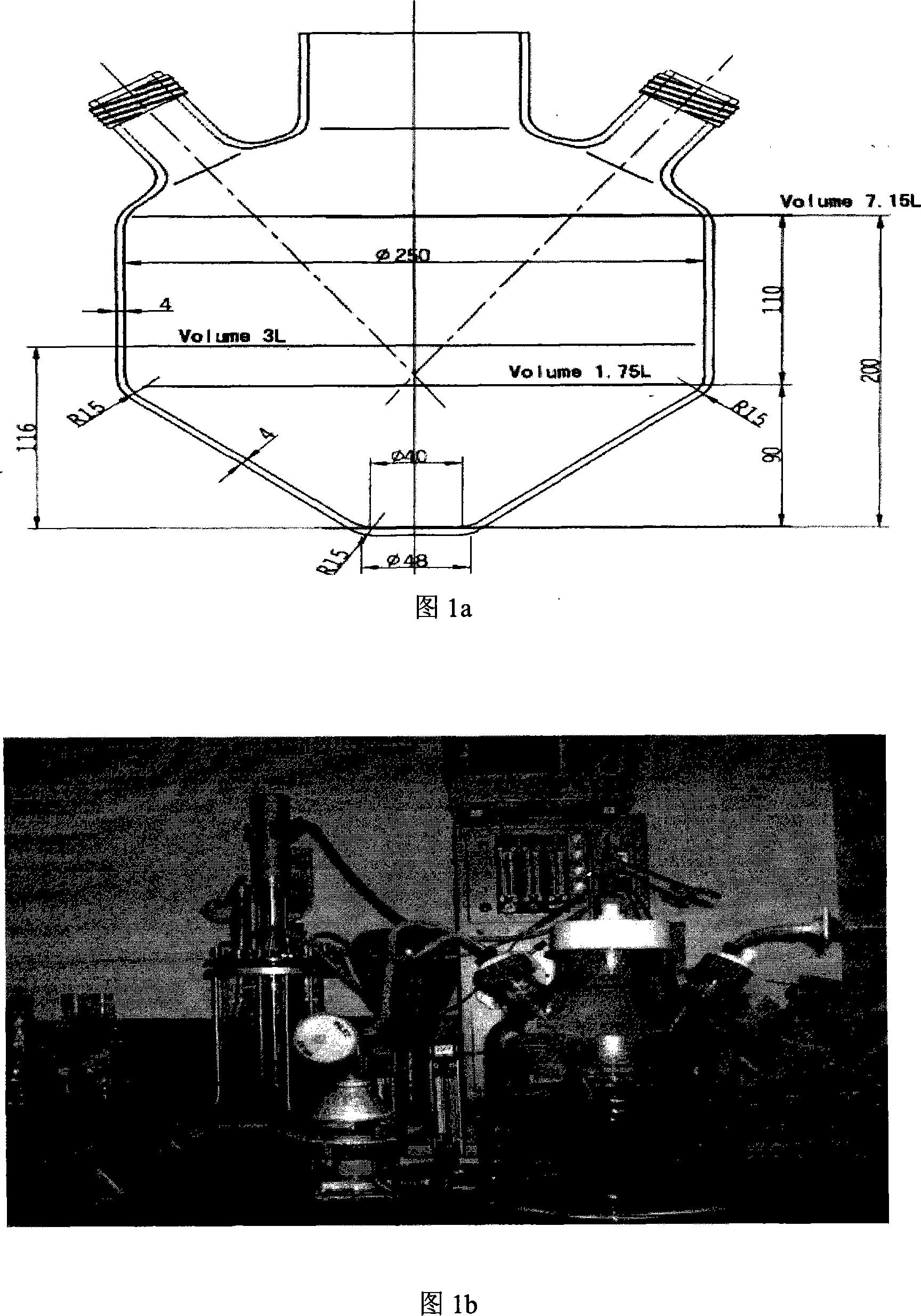

[0055] Embodiment 3: the research of 3 liters of wide-bodied flat conical bottom shake flasks

[0056] The 3-liter wide-body flat-conical bottom cell reactor is equipped with an oxygen tube device or air injection (Fig. 1a, b), and the medium in the working volume has a large surface area, which is conducive to the absorption of oxygen by the medium (per cubic centimeter of medium The surface area of the reactor is greater than 0.143cm2), and the wide-body flat-conical bottom cell reactor is equipped with an air injection device at the bottom to extend the escape journey of the air (containing 21% oxygen) (figure a, b). The oxygen tube device at the bottom is used as a low flow meter to control the low flow rate of pure oxygen. The shaker can make the culture volume spread to the tank wall, and it is easy to form a thin culture layer to extend the culture surface area and improve aeration.

[0057] CHO cell lines were used to express TNFR1-Fc-IL-1ra, IL-18bp-Fc-IL-1ra, VEGFR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com