Plush knitwear post-finishing electric control cabinet

A technology of electrical control cabinets and knitted fabrics, applied in the direction of motor generator control, electrical components, control systems, etc., can solve the problems of unsatisfactory electrical control devices, expensive frequency conversion speed regulators, etc., and achieve complete functions, simple structure, manipulate simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

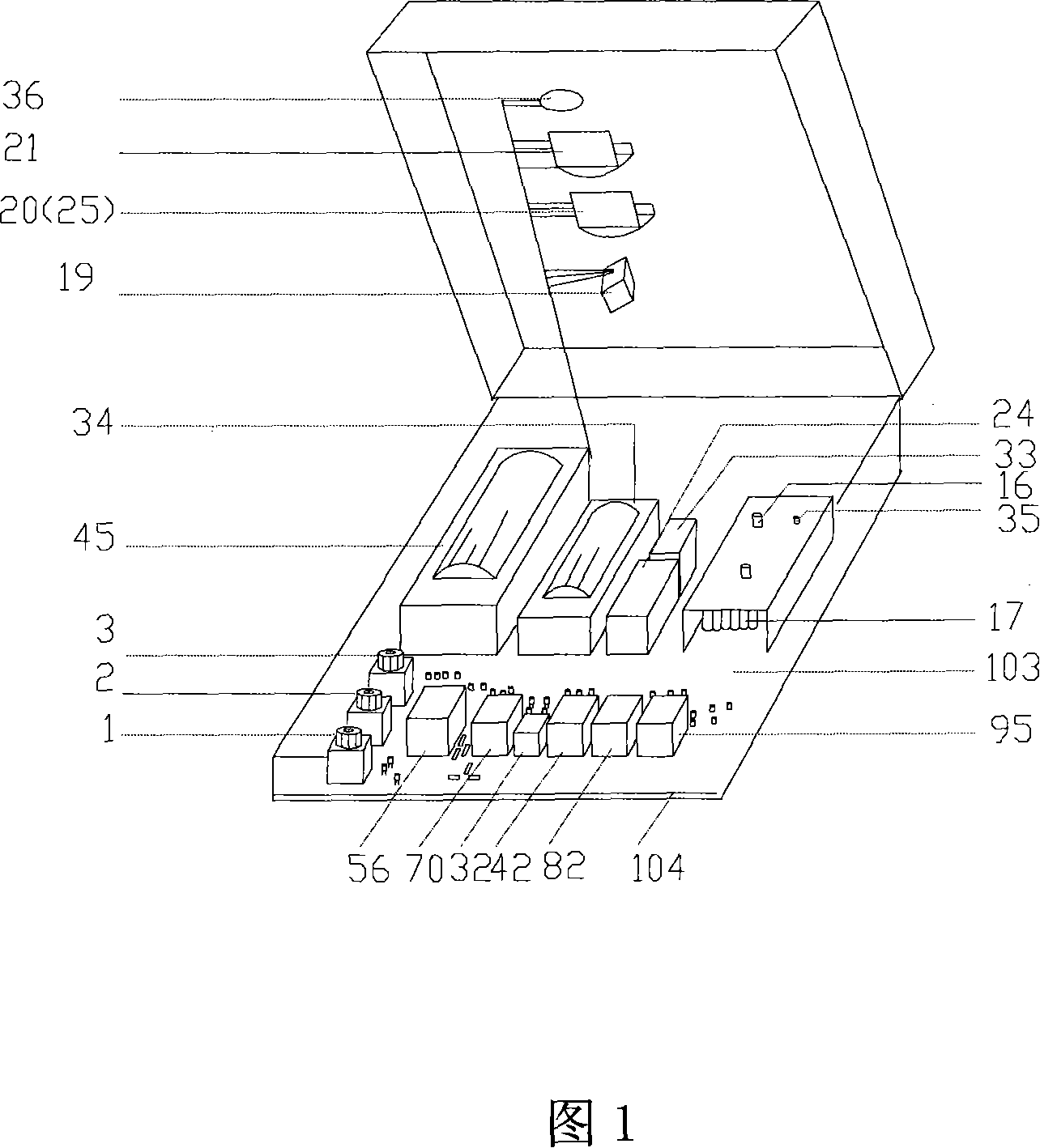

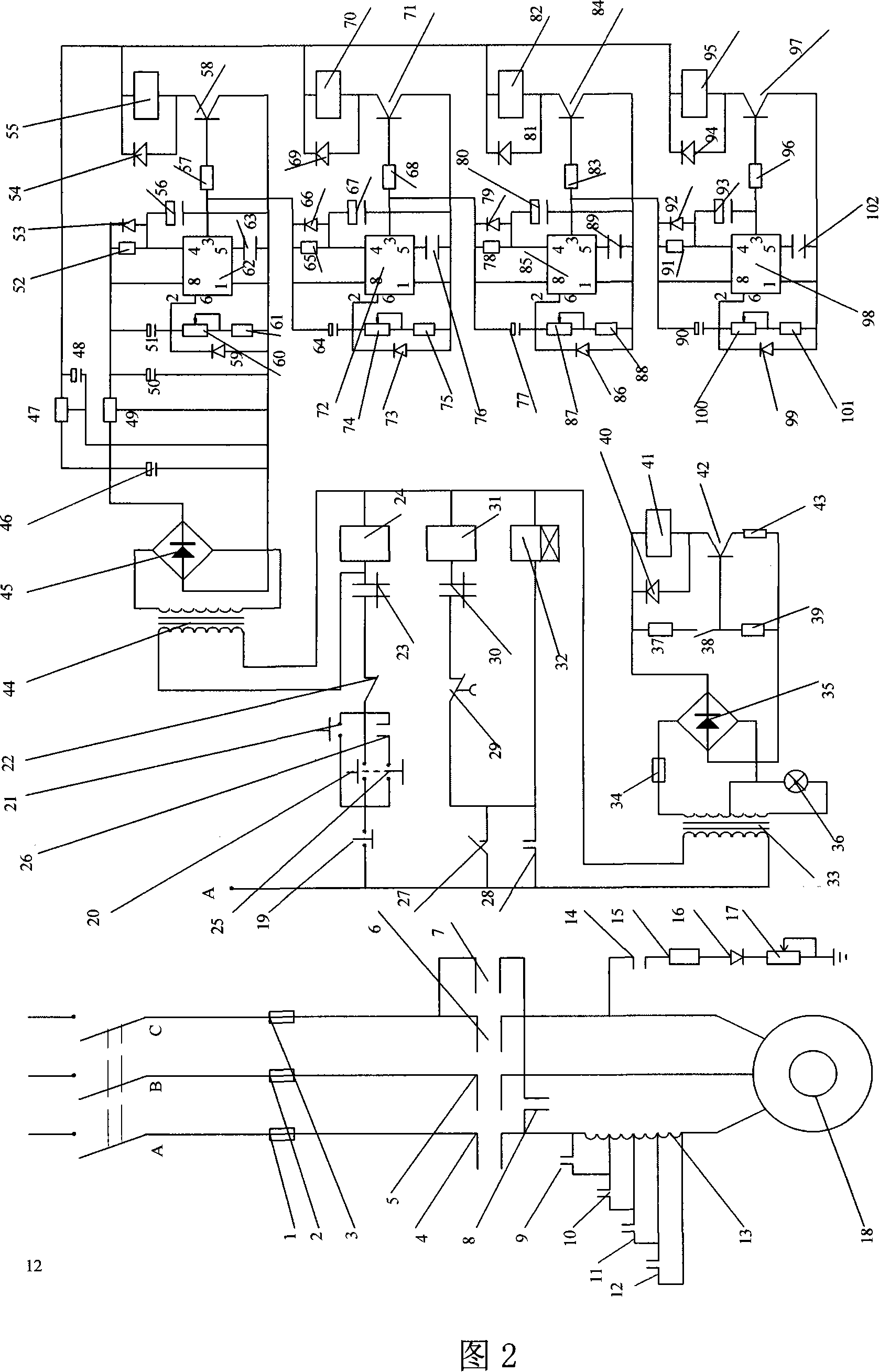

[0009] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings

[0010] In this embodiment, fuses 1 to 3 use 15A reactors 13 with C-shaped iron cores, wound with Φ1.5mm wires, the total reactance is 20mH, each section is 5mH, and there are 4 taps; the second tube 16 10A / 500V, 53, 66, 79 and 92 all use 1N4148 type, 54, 69, 81 and 94 use 1N40071A / 1000V, 59, 76, 86 and 99 all use fast discharge 2AP9 type, rectifier 35 and 45 are all It is a bridge rectifier, that is, 4×1N4007, 1A / 1000V; integrated regulator 47 adopts 7842 type, 1A / 24V, 49 adopts 7812 type 1A / 12V; capacitor 51 adopts 10μF / 2.5F; resistors 61, 75, 88 are all Use 10K1 / 4W; potentiometers 60, 74, 87 and 100 all use 10K1 / 4W, resistors 52, 65, 78 and 91 all use 3K1 / 4W; capacitors 56, 67, 870 and 91 all use 3K1 / 4W; capacitor 56 , 67, 80 and 93 all use 10μF / 25V, 48 use 1000μF / 50V, 50 and 51 both use 200μF / 25V; transformer 33 and 2W; fuse 34 is 0.5A; time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com