Multi- structure motor enclosure aluminium alloy hot-extrusion die

A technology of hot extrusion die and hollow structure, which is applied in the direction of metal extrusion die, manufacturing motor generators, electrical components, etc., can solve the problems of insufficient strength of the upper die, difficulty in adjusting the flow rate, and low output, so as to ensure the consistency of flow rate , metal flow balance, and the effect of improving mold output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

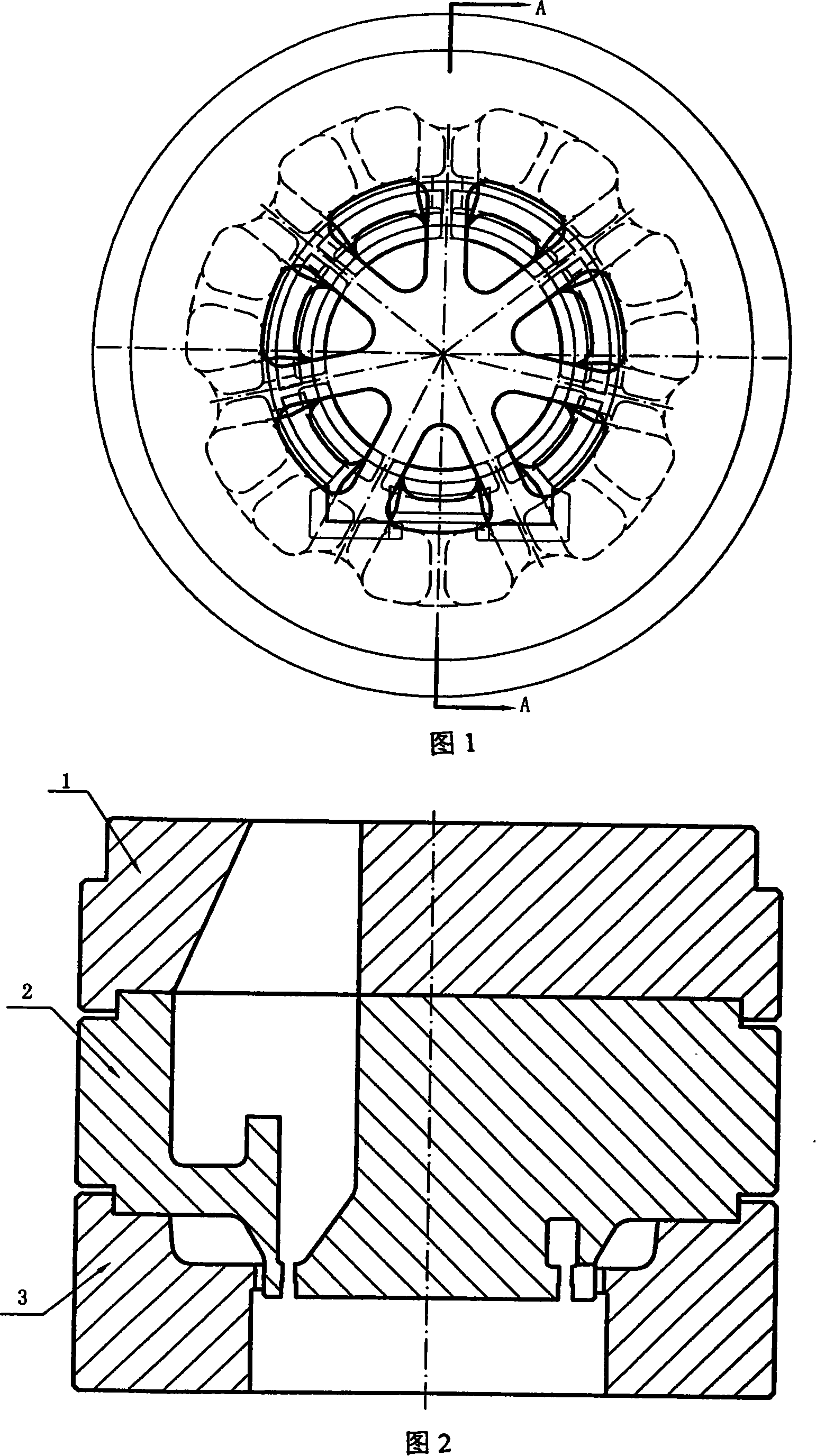

[0031] Referring to Figs. 1-2, the present invention is a multi-hollow structure aluminum alloy hot extrusion die, which is composed of a diversion die 1, an upper die 2 and a lower die 3 stacked front and back.

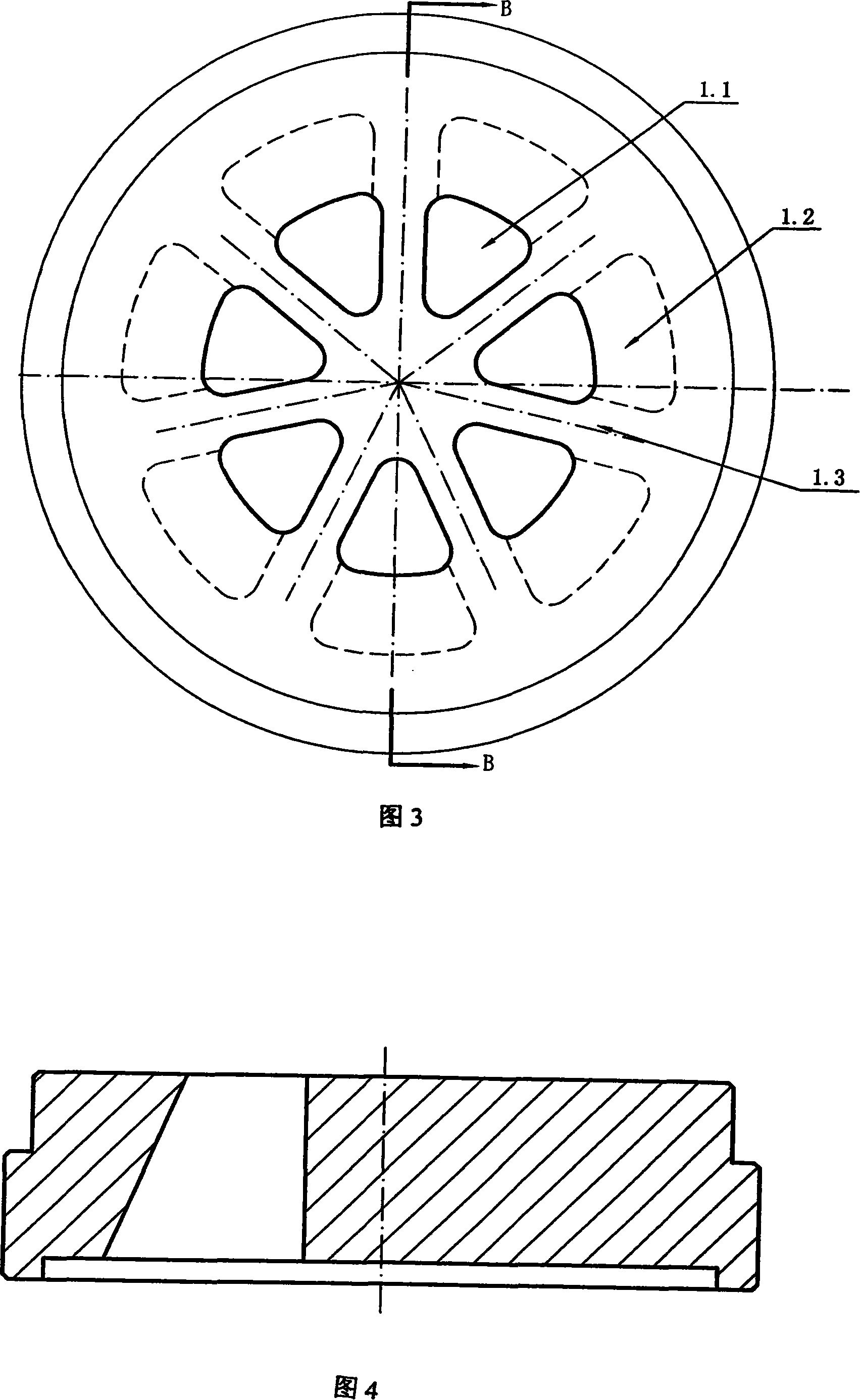

[0032] Referring to Figures 3-4, the feed surface of the diversion mold 1 is provided with seven bridges 1.3, and seven diversion holes 1.1 are formed between the bridges 1.3, and the diversion holes 1.1 expand to form diversion hole extensions 1.2.

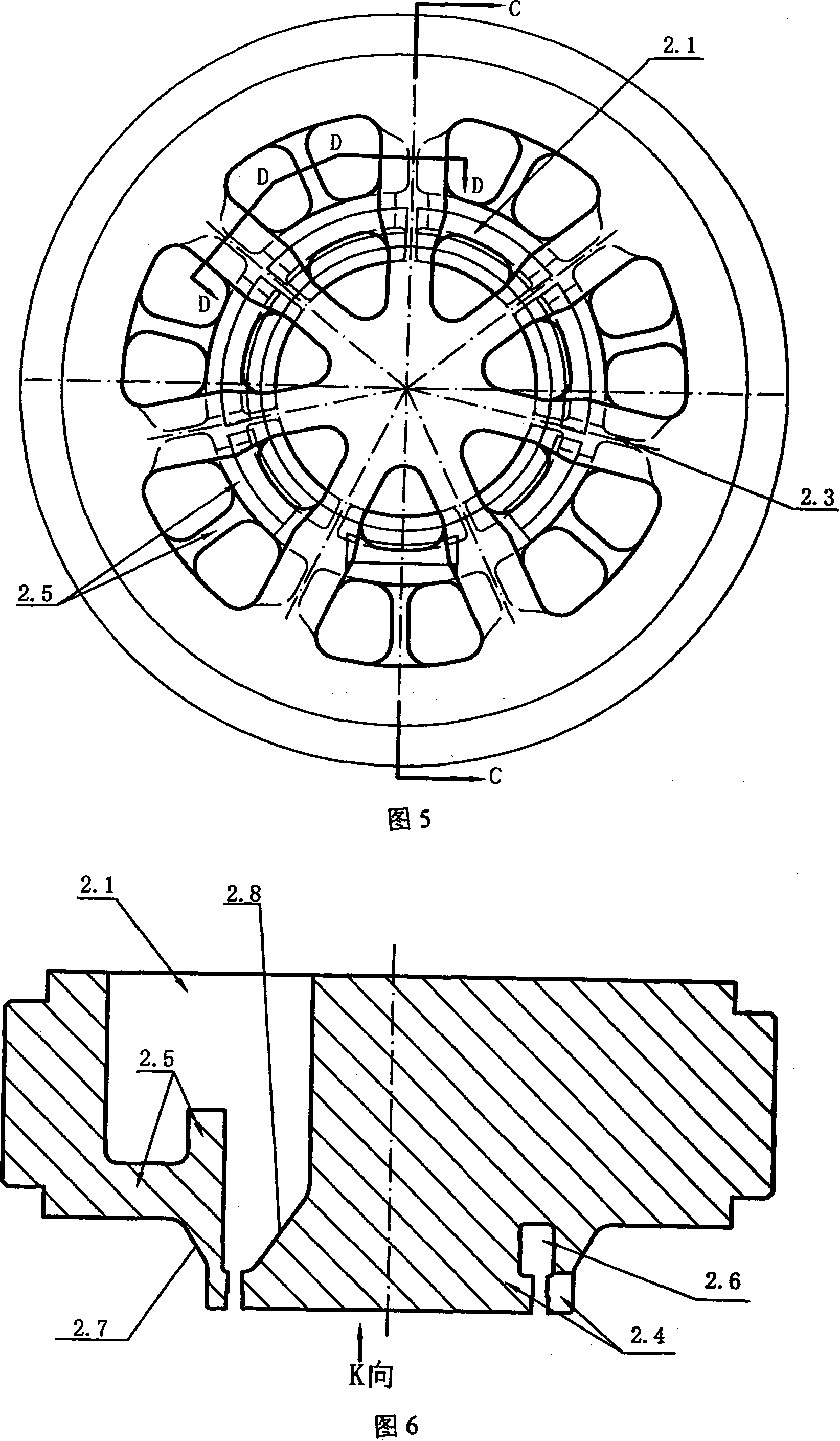

[0033] Referring to Figures 5 to 8, the feed surface of the upper die 2 is provided with seven bridge positions 2.3, and seven feed distribution holes 2.1 are formed between the bridge positions 2.3, and the discharge face of the upper die 2 is provided with 21 outlets. Dividing holes 2.2 at the material outlet, and twenty-one distributing holes 2.2 at the outlet are divided into inner and outer circles, of which there are fourteen in the outer circle and seven in the inner circle, and each feeding disposition on the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com