Liquid crystal display

A technology of liquid crystal display and liquid crystal layer, applied in static indicators and other directions, can solve problems such as inability to observe, achieve the effects of increasing convenience, improving pass rate, and overcoming accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

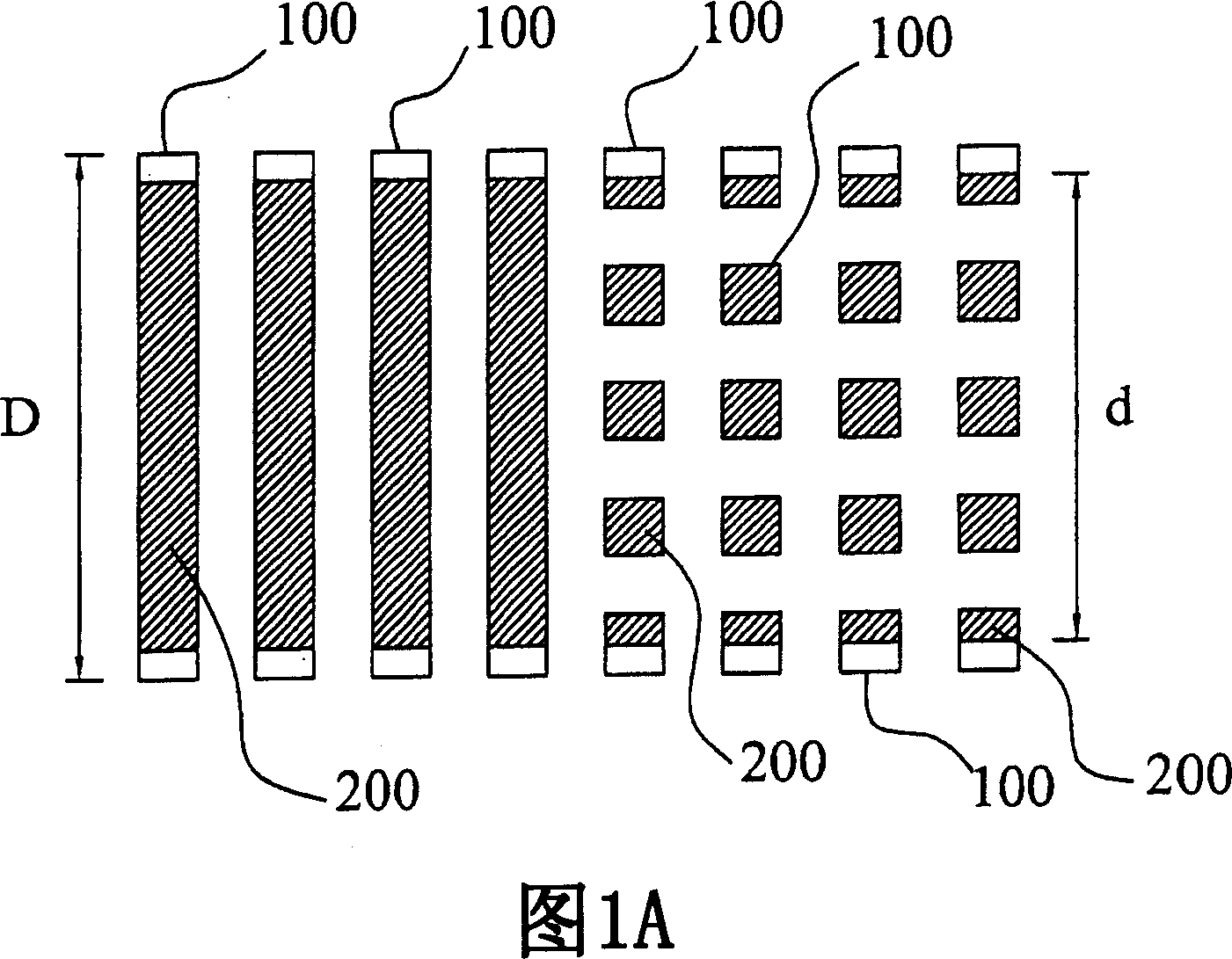

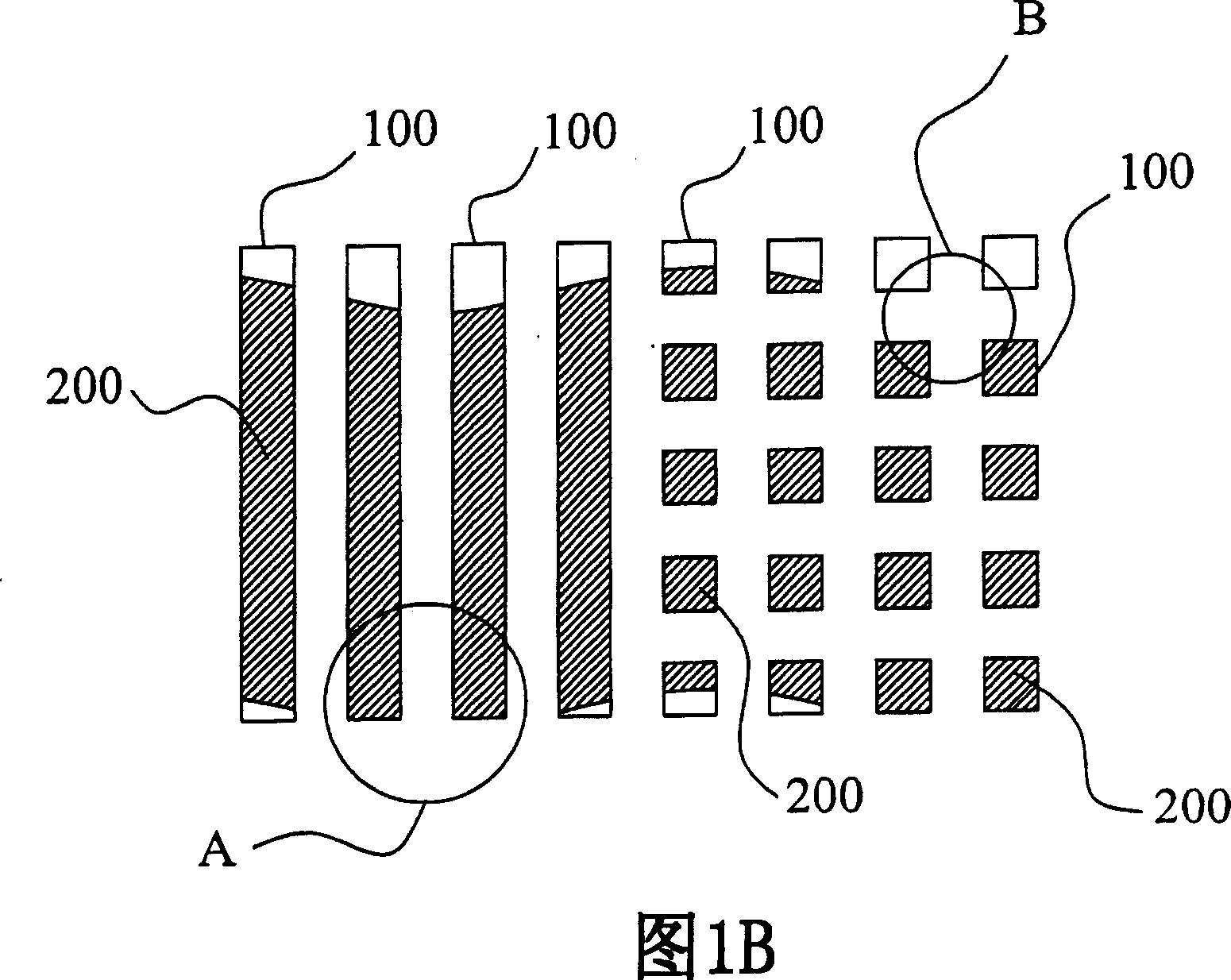

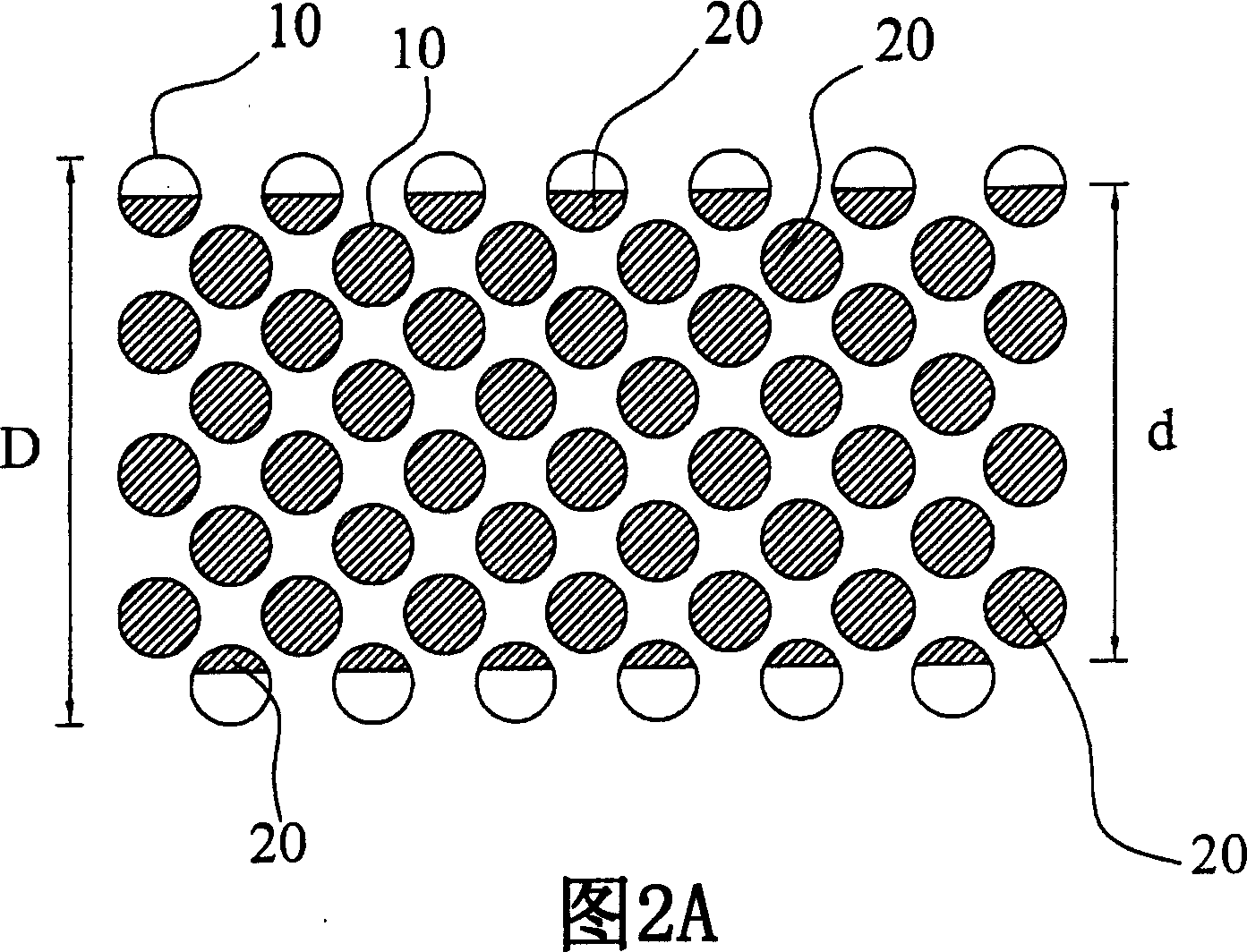

[0039] FIG. 3A is a schematic plan view of a liquid crystal display according to an embodiment of the present invention. Fig. 3B is an enlarged cross-sectional schematic diagram according to the section line A-A' in Fig. 3A. In this embodiment, the liquid crystal display comprises a first substrate 30, and this first substrate 30 has a black matrix layer 32, and a second substrate 40 is arranged on the relative position of the first substrate, and the second substrate has a thin film transistor (on the figure not shown), a liquid crystal layer 52 is filled between the first substrate 30 and the second substrate 40 , and the first substrate 30 and the second substrate 40 are bonded by the sealant 20 . The sealant 20 is coated on the non-display area and surrounds the display area 50 of the liquid crystal display panel. There is a liquid crystal layer 52 in the liquid crystal display area. The sealant 20 will leave a liquid crystal injection port in a specific area for subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com