Assembled blast wall and inverted type road lunge combination protection device

An explosion-proof wall, prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of the protection device being difficult to meet the protection requirements, high cost, unable to prevent the direct impact of vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

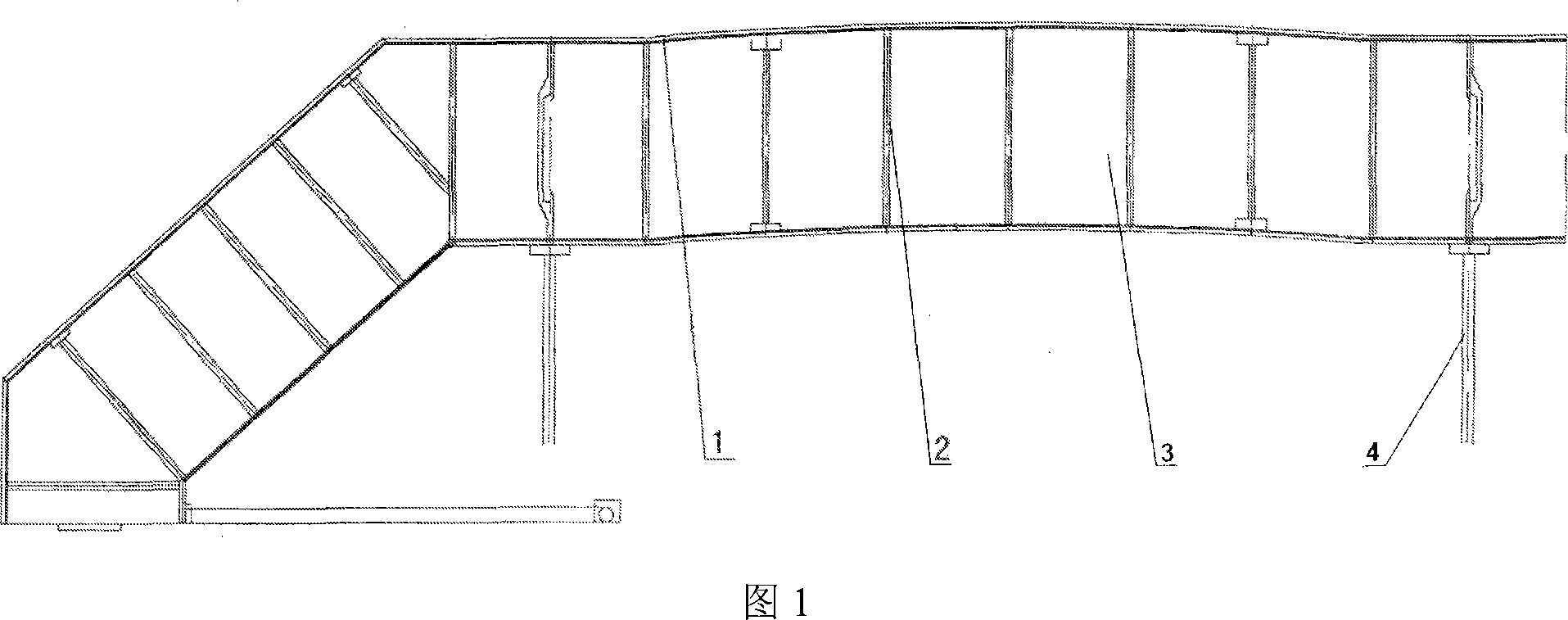

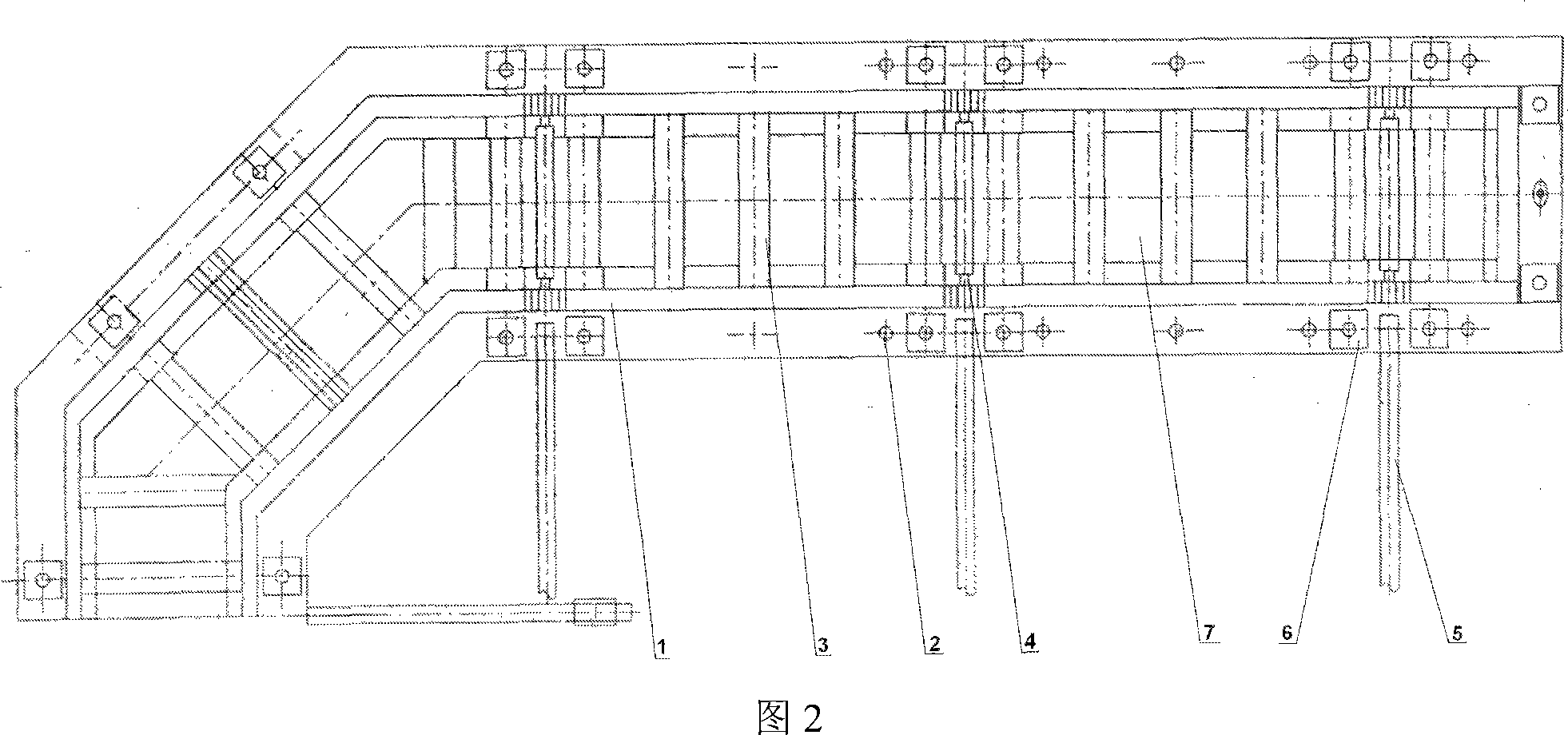

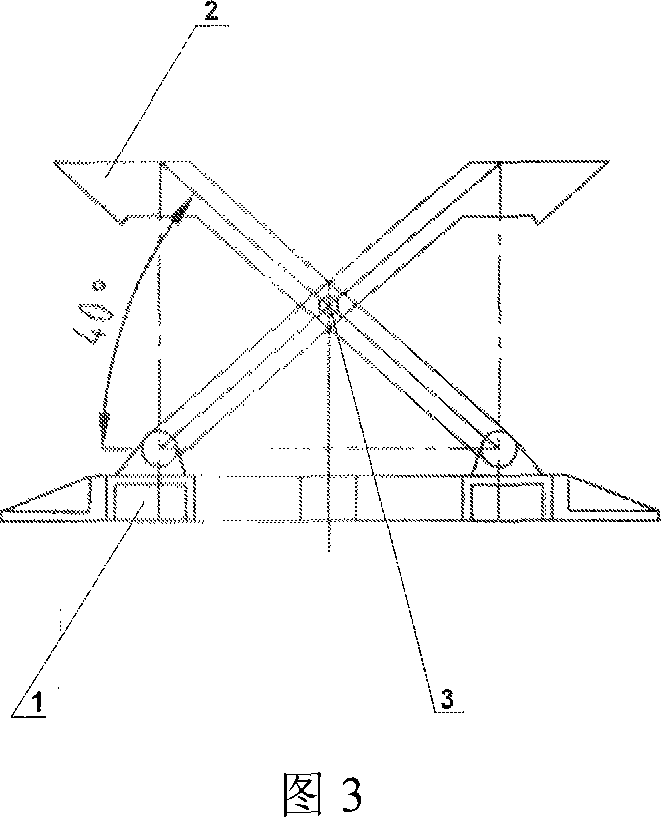

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0016] The structure and main parameters of the device are as follows: ① The integrally assembled explosion-proof wall is composed of three rows of double-layer steel plates with internal reinforcement and concrete, which is shallowly curved outward, filled with lightweight aggregate concrete, and the unit members are long 2.4m, 0.4m wide, 2.5m high, 4500kg in weight, with two adjustable length diagonal supports on the back; The connection between the inner filling sand and the steel plate adopts the specially designed "U" spring steel pin locking connection method, which is fast and reliable. The unit component is 1.0m long, 0.5m wide, and 2.5m high, and the heaviest component is 90kg , There are two adjustable length diagonal supports on the back. The two types of explosion-proof walls are fixedly connected to the ground, and fixed to the ground with expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com