Process for making concrete pile and its special-purpose equipment

A technology of concrete pile and manufacturing process, which is applied in the direction of strengthening molding, etc. It can solve the problems of affecting product quality, slow feeding speed, difficult to use requirements, etc., and achieve the effect of saving manpower, controlling waste, and dense joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

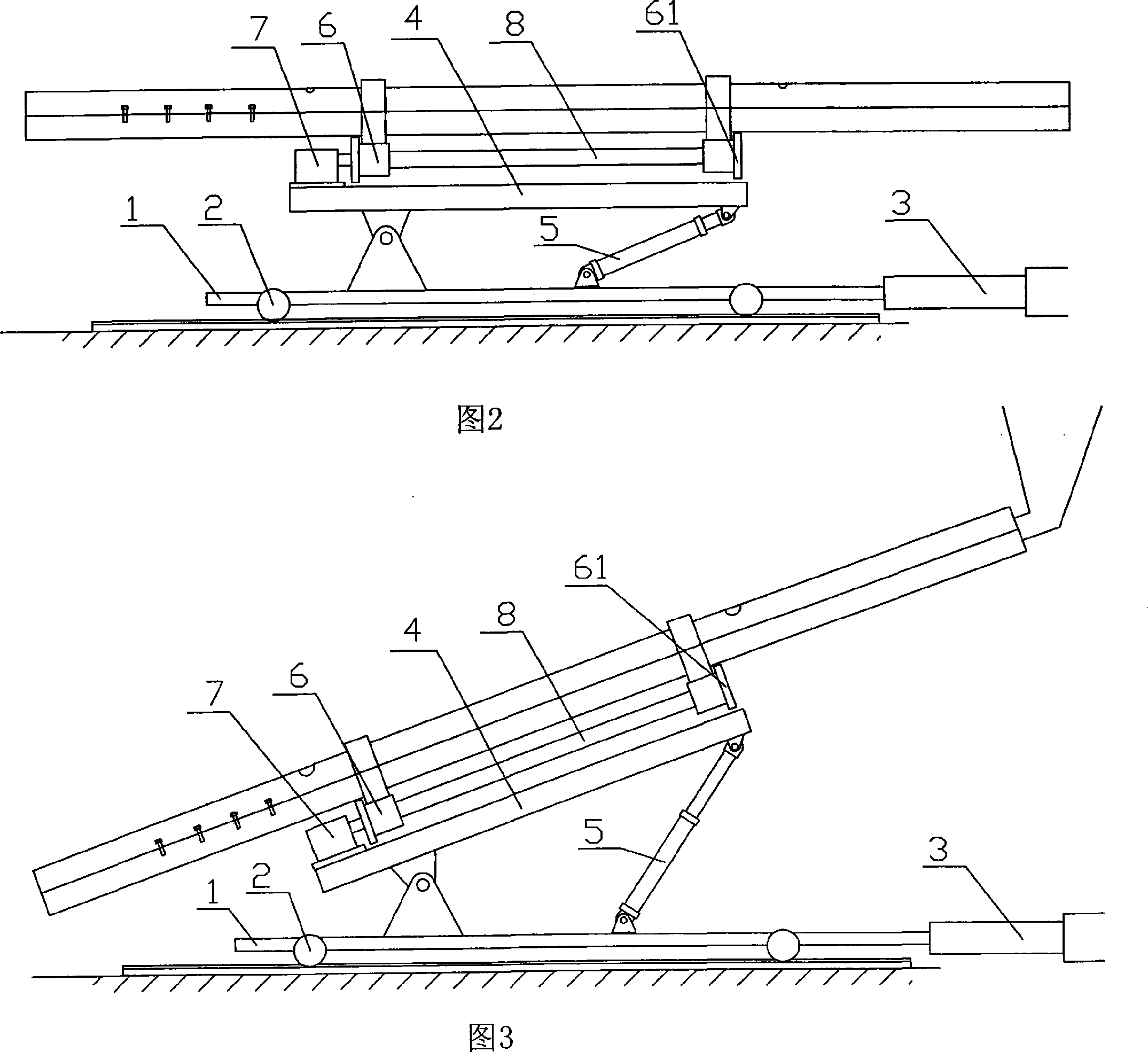

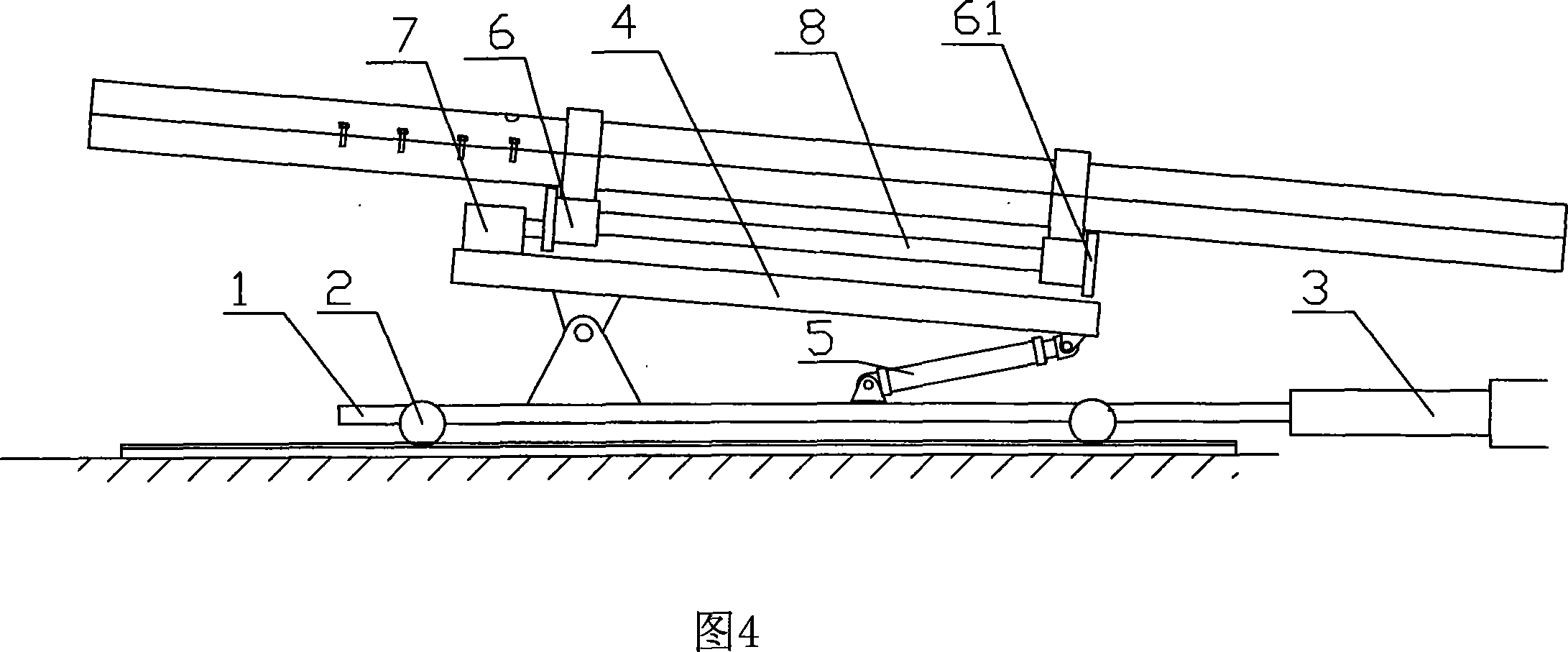

[0017] With reference to Fig. 2, Fig. 3, Fig. 4, a kind of manufacturing process of concrete pile, its steps are as follows:

[0018] 1) Install the reinforcement cage and skeleton of the concrete pile with the bottom mold and surface mold of the mould, and then place it on the rotating device;

[0019] 2) Tilt the concrete pile mold to a suitable angle, and make the feed port of the mold connect with the discharge port of the concrete hopper;

[0020] 3) Start the rotating device to make the mold rotate at a certain speed, and pour the pre-mixed concrete into the mold;

[0021] 4) After the input is completed, block the feed port of the mold with a plug, then tilt the mold downward, and rotate the mold properly.

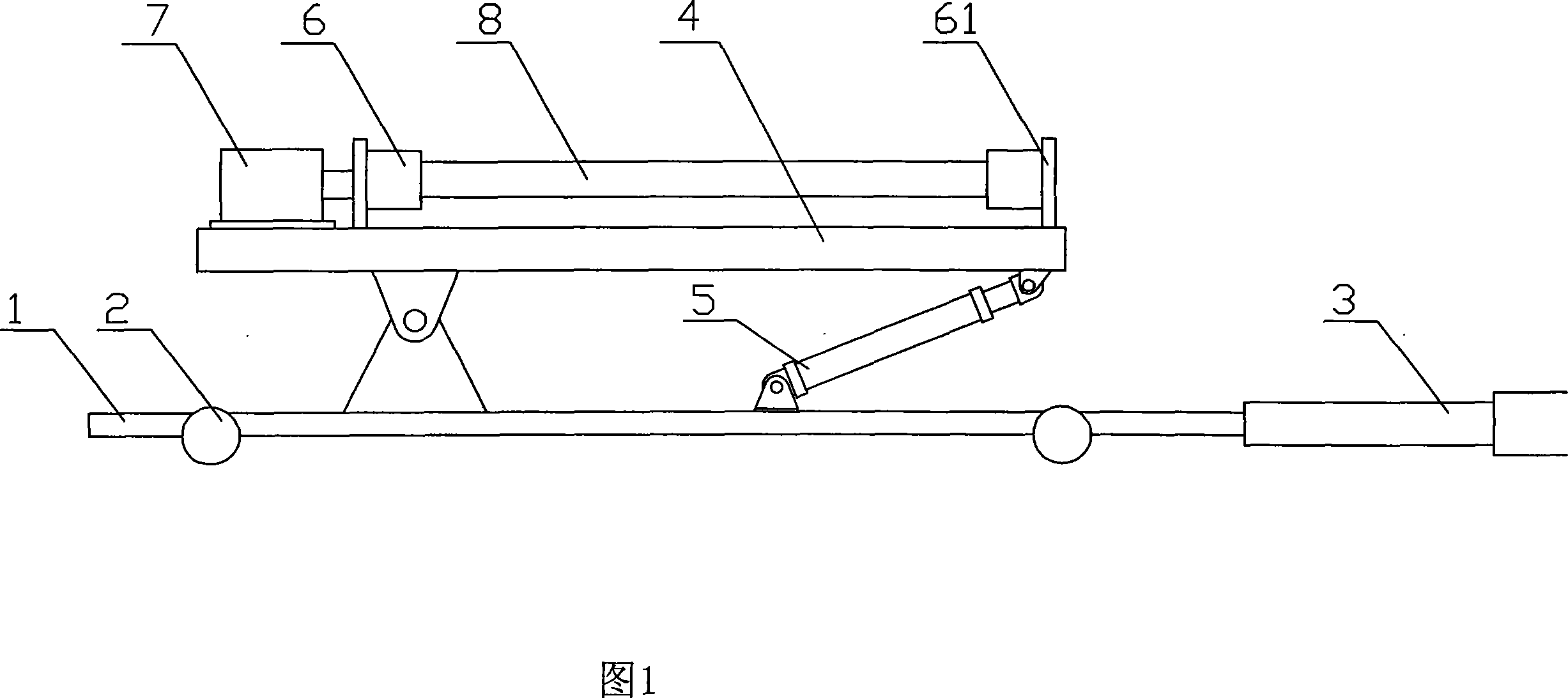

[0022] Referring to Fig. 1, a special feeding device for realizing the manufacturing process includes a bottom frame 1, and sliding wheels 2 are arranged on the left and right sides of the bottom frame 1. In order to make the sliding wheels 2 rotate more smoothly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com