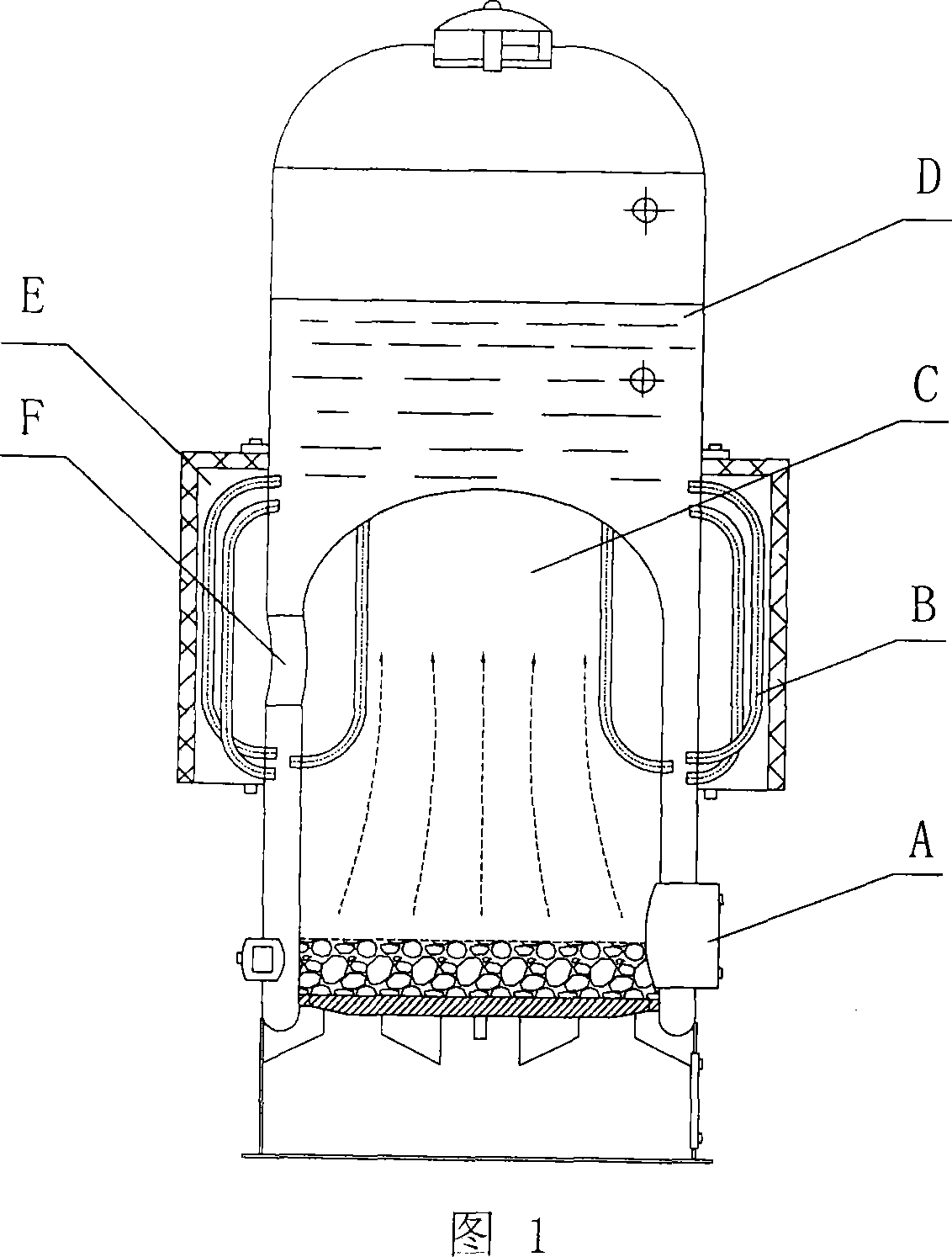

Vertical smokeless steam boiler of Venturi tube effect

A Venturi tube and steam boiler technology, applied in steam boilers, steam generation, solid fuel combustion, etc., can solve problems such as coal-fired black smoke emissions, and achieve environmental protection, long service life, and good combustion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the above-mentioned accompanying drawings.

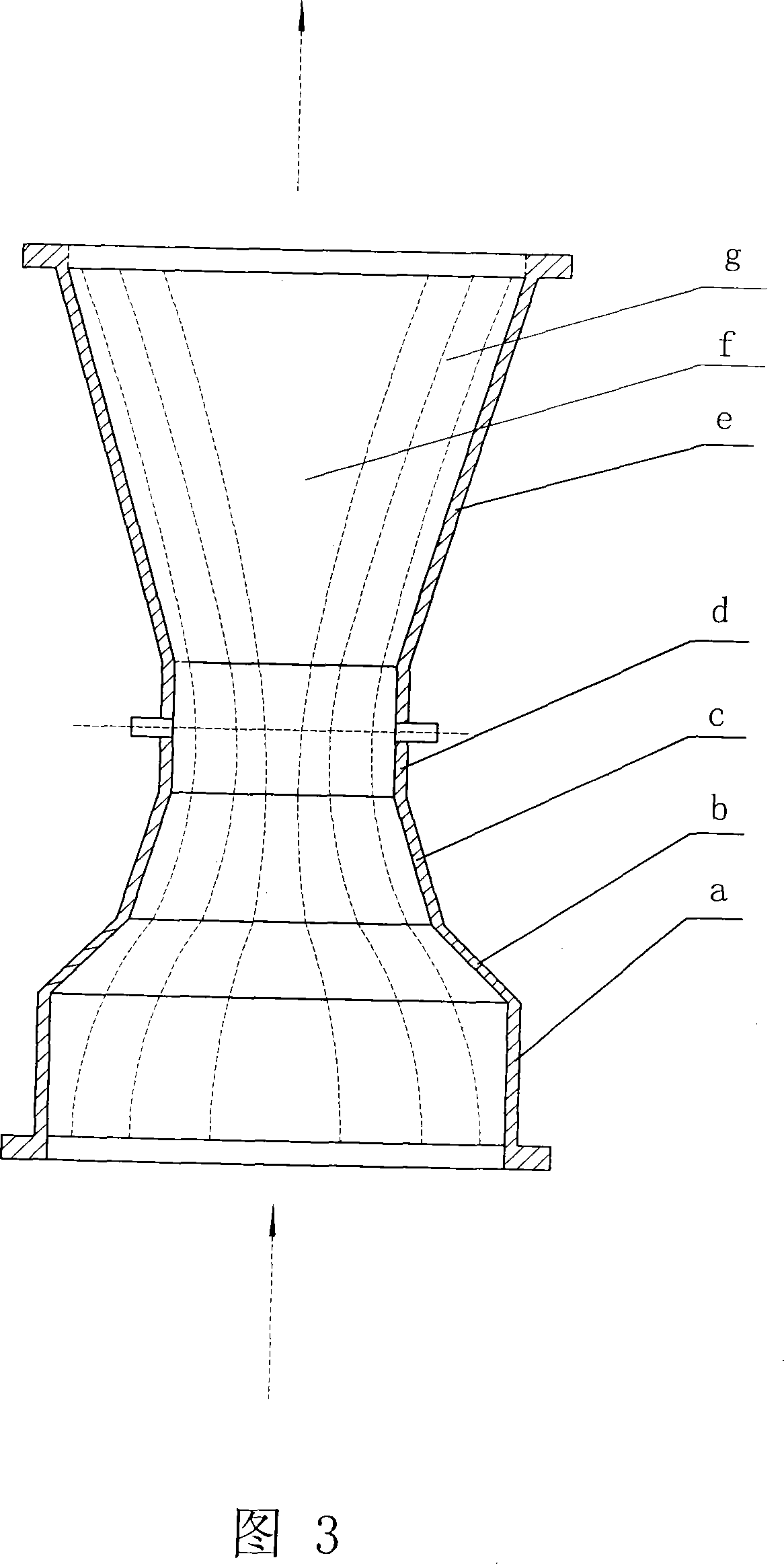

[0031] Figure 3 shows the structure and aerodynamic principle of the Venturi tube.

[0032] Inject a certain pressure and a certain flow rate of airflow from the inlet of the Venturi tube. The airflow is gradually compressed from the inlet section a through the contraction sections b and c. When it reaches the cylindrical throat d, the density is the highest and the flow velocity is also the highest. Then The airflow g does not spray upwards through the throat in a cylindrical shape, but sticks to the inner wall of the scattering cone e in a conical form, and diffuses and sprays upwards in a hollow trumpet shape. This is the aerodynamic "lee side adsorption effect" of the Venturi tube ". How did this phenomenon come about? This is because the airflow is compressed and accelerated when it passes through the cylindrical throat d, and it is sprayed upwards in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com