Electrochemical depositer with inductive anode

A deposition device and electrochemical technology, applied in the direction of electroforming, electrolysis process, etc., can solve the problems of poor localization of local electrochemical deposition and low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

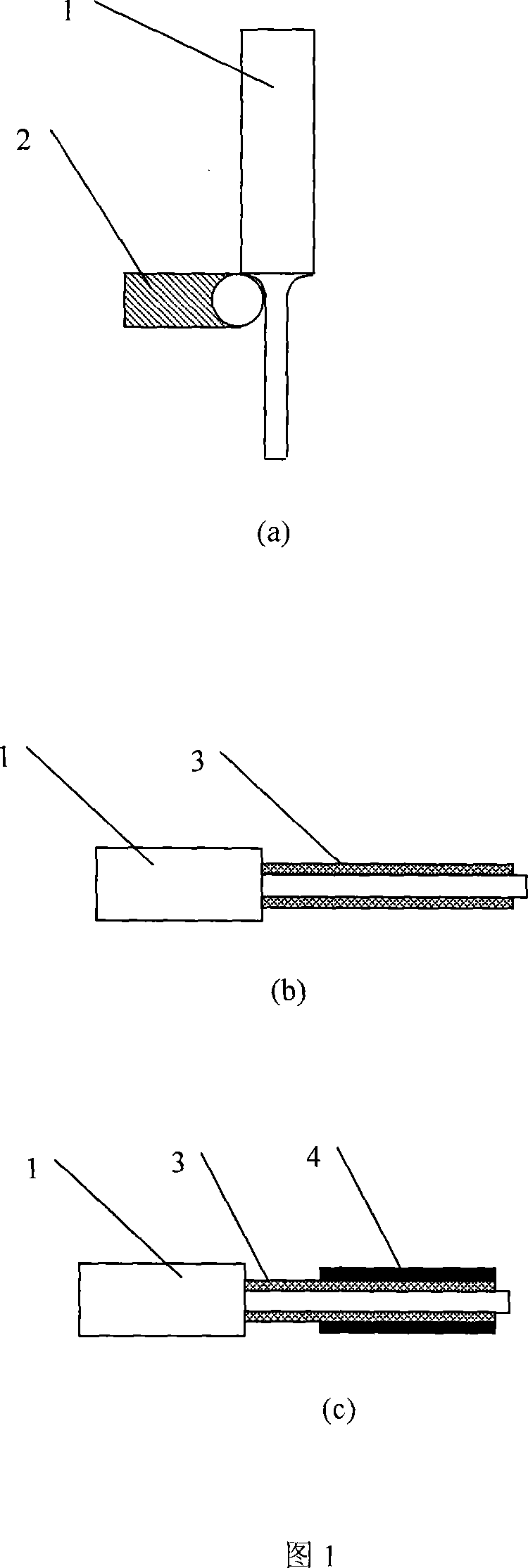

[0012] Below in conjunction with Fig. 1, Fig. 2 concretely illustrate the implementation of the present invention -- "using the electrochemical deposition device of induced anode".

[0013] As shown in Figure 1: the local electrochemical deposition induction anode is composed of three layers of materials: a central platinum wire 1, an insulating layer 3 and an outer conductive layer 4.

[0014] The manufacturing method of this induced anode is:

[0015] (1) As shown in Figure 1(a), use a wire electrode spark grinding (WEDG) device 2 to process a platinum wire 1 with a diameter of tens to hundreds of microns, and keep a larger diameter at one end for easy assembly. Clamp, the diameter of the other end depends on the size requirements of the processed parts.

[0016] (2) As shown in Fig. 1(b), insulate or coat the side wall of the small end of the platinum wire 1. The insulating material can be Teflon, plexiglass, epoxy resin and the like. When insulating, the end of the plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com