Color SBS modified waterproof asphalt material

A technology for modified asphalt and waterproof coatings, applied in the field of coatings, can solve problems such as the health impact of production operators, high toxicity of benzene-based solvents, single color, etc., and achieve the effects of energy saving, easy operation and good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

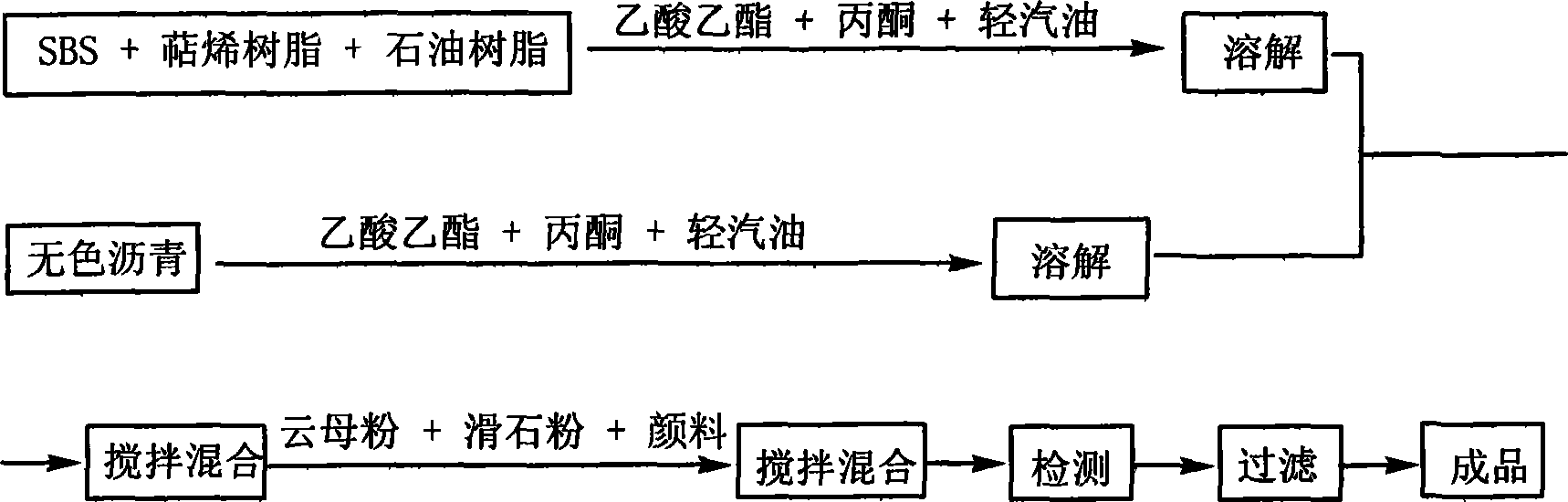

Image

Examples

Embodiment 1

[0029] White SBS modified bitumen waterproof coating

[0030] formula:

[0031] Raw material name Mass percentage (%)

[0032] SBS 12

[0033] Colorless asphalt 21

[0034] Terpene resin 5

[0035] Petroleum resin 6

[0036] light gasoline 20

[0037] Acetone 10

[0038] Ethyl acetate 15

[0041] Titanium dioxide 7

[0042] crafting process:

[0043] 1. Preparation of SBS solution: Take 10kg of light gasoline, 5kg of acetone and 10kg of ethyl acetate, add 12kg of SBS, 5kg of terpene resin and 6kg of petroleum resin, stir to dissolve completely, and set aside.

[0044] 2. Preparation of asphalt solution: Take 10kg of light gasoline, 5kg of acetone and 5kg of ethyl acetate, add 21kg of colorless asphalt, stir to dissolve completely, and set aside.

[0045] 3. Preparation of colored SBS modified asphalt waterproof coating: mix SBS solution and asphalt solution, add 2kg mica powder, 2kg talc powder and 7kg tit...

Embodiment 2

[0047] Green SBS modified asphalt waterproof coating

[0048] formula:

[0049] Raw material name Mass percentage (%)

[0050] SBS 12

[0051] Colorless asphalt 21

[0052] Terpene resin 5

[0053] Petroleum resin 6

[0054] light gasoline 20

[0055]Acetone 10

[0056] Ethyl acetate 15

[0057] Mica powder 2

[0058] Talc powder 2

[0059] Chrome Oxide Green 7

[0060] crafting process:

[0061] 1. Preparation of SBS solution: Take 10kg of light gasoline, 5kg of acetone and 10kg of ethyl acetate, add 12kg of SBS, 5kg of terpene resin and 6kg of petroleum resin, stir to dissolve completely, and set aside.

[0062] 2. Preparation of asphalt solution: Take 10kg of light gasoline, 5kg of acetone and 5kg of ethyl acetate, add 21kg of colorless asphalt, stir to dissolve completely, and set aside.

[0063] 3. Preparation of colored SBS modified asphalt waterproof coating: mix SBS solution and asphalt solution, add 2kg of mica powder, 2kg of talcum powde...

Embodiment 3

[0065] Red SBS modified asphalt waterproof coating

[0066] formula:

[0067] Raw material name Mass percentage (%)

[0068] SBS 12

[0069] Colorless asphalt 21

[0070] Terpene resin 5

[0071] Petroleum resin 6

[0072] light gasoline 20

[0073] Acetone 10

[0074] Ethyl acetate 15

[0075] Mica powder 2

[0076] Talc powder 2

[0077] Iron Oxide Red 7

[0078] crafting process:

[0079] 1. Preparation of SBS solution: Take 10kg of light gasoline, 5kg of acetone and 10kg of ethyl acetate, add 1kg of SBS, 5kg of terpene resin and 6kg of petroleum resin, stir to dissolve completely, and set aside.

[0080] 2. Preparation of asphalt solution: Take 10kg of light gasoline, 5kg of acetone and 5kg of ethyl acetate, add 21kg of colorless asphalt, stir to dissolve completely, and set aside.

[0081] 3. Preparation of colored SBS modified asphalt waterproof coating: mix SBS solution and asphalt solution, add 2kg mica powder, 2kg talc powder and 7kg iron oxide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com