Diamond cutting bit

A technology of diamond cutter head and diamond saw blade, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., which can solve the problem of affecting the cutting speed, the service life of diamond saw blades, the aggravation of the fracture of the alveolar cutter head, and the uneven wear of the blade And other problems, to achieve the effect of uniform force, uniform wear and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

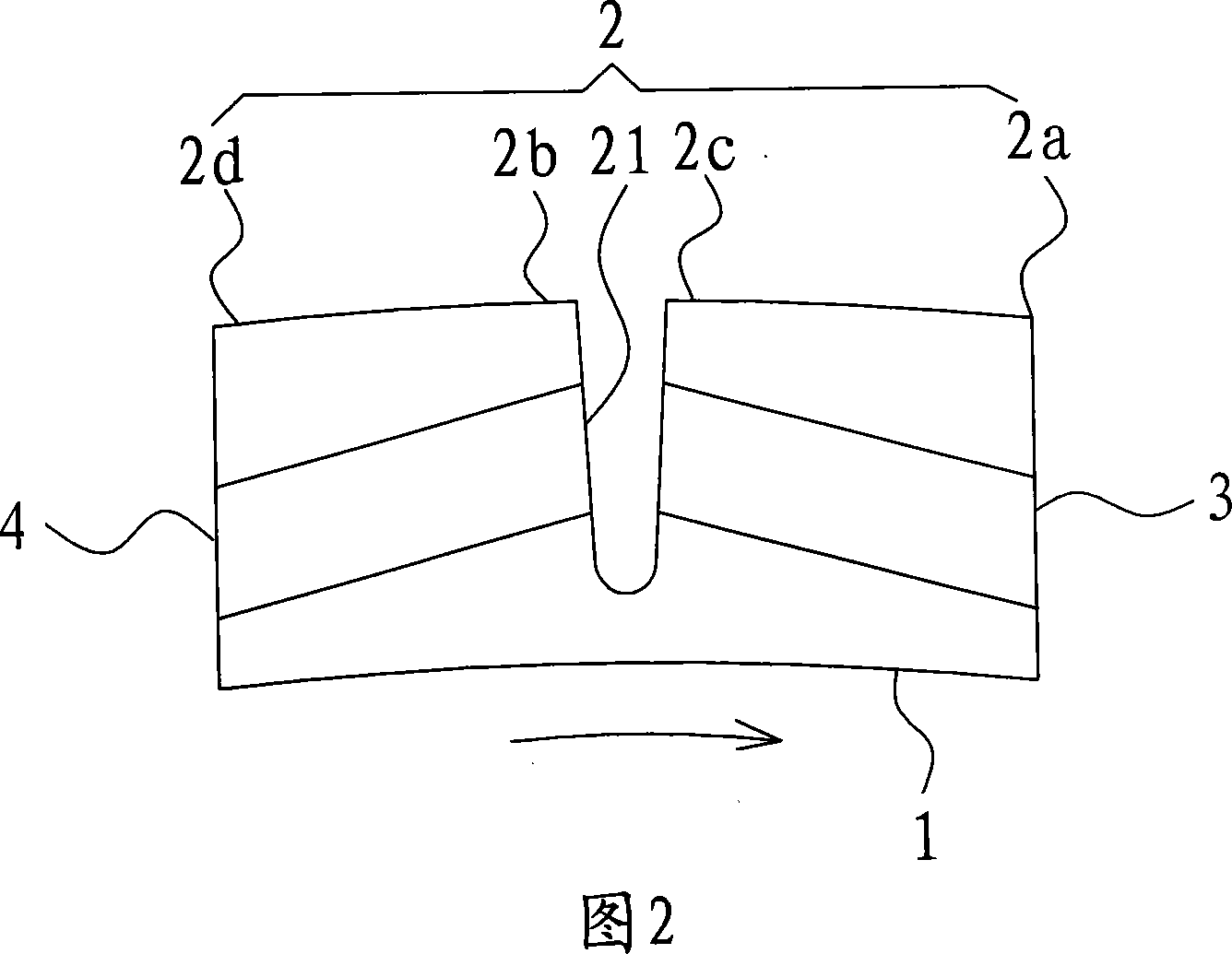

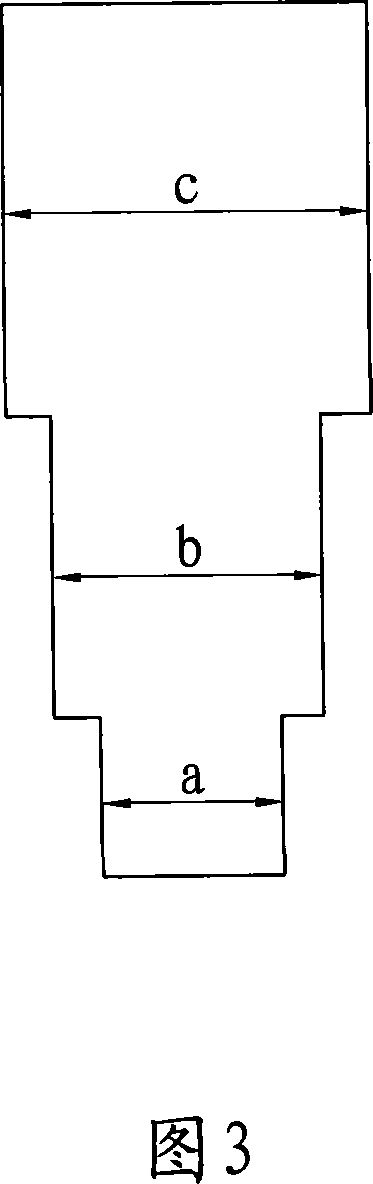

[0011] Referring to Fig. 2 and Fig. 3, the embodiment discloses a diamond cutter head, which includes the inner edge 1 of the cutter head and the outer edge 2 of the cutter head, along the cutting direction shown by the arrow in Fig. Side 3 and the cutter head rear side 4, the outer edge of the cutter head 2 is provided with a groove 21 in the middle, and the groove 21 extends to the inner edge of the cutter head to the radial length of the entire diamond cutter head for about three minutes. In the second position, from the inner edge 1 of the cutter head to the outer edge 2 of the cutter head, the diamond cutter head has three thicknesses: thickness a, thickness b and thickness c, and a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com