Puffed corn machine

A popcorn and processing machine technology, applied in food preparation, application, food science, etc., can solve the problem of not being able to promote the processing of popcorn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

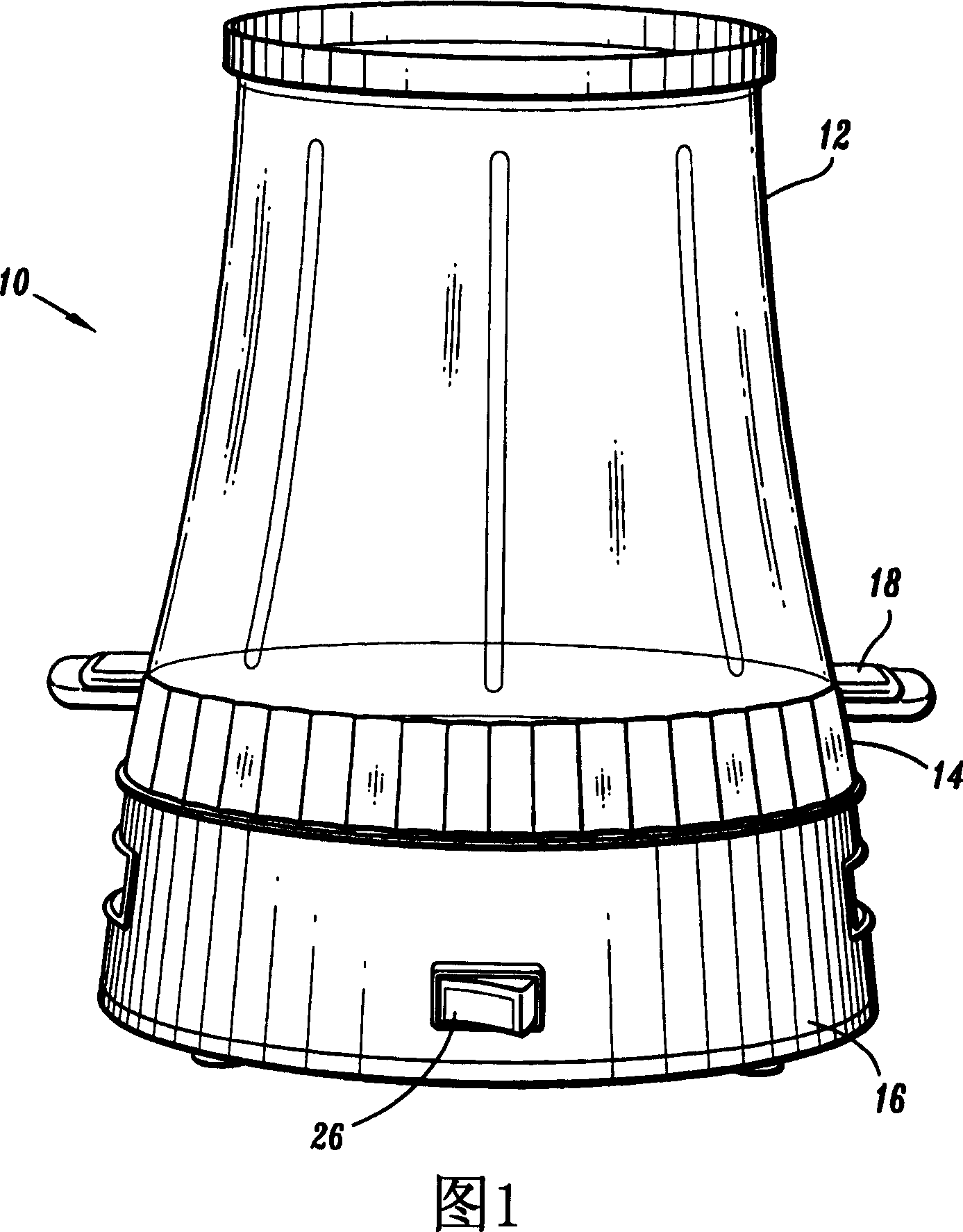

[0011] Referring to FIG. 1 , there is shown a popcorn processing apparatus 10 including a container 12 connected to a processing tray assembly 14 and a base 16 in accordance with a preferred embodiment of the present invention. Base 16 is adapted to rest on a generally flat surface, such as a counter or table top.

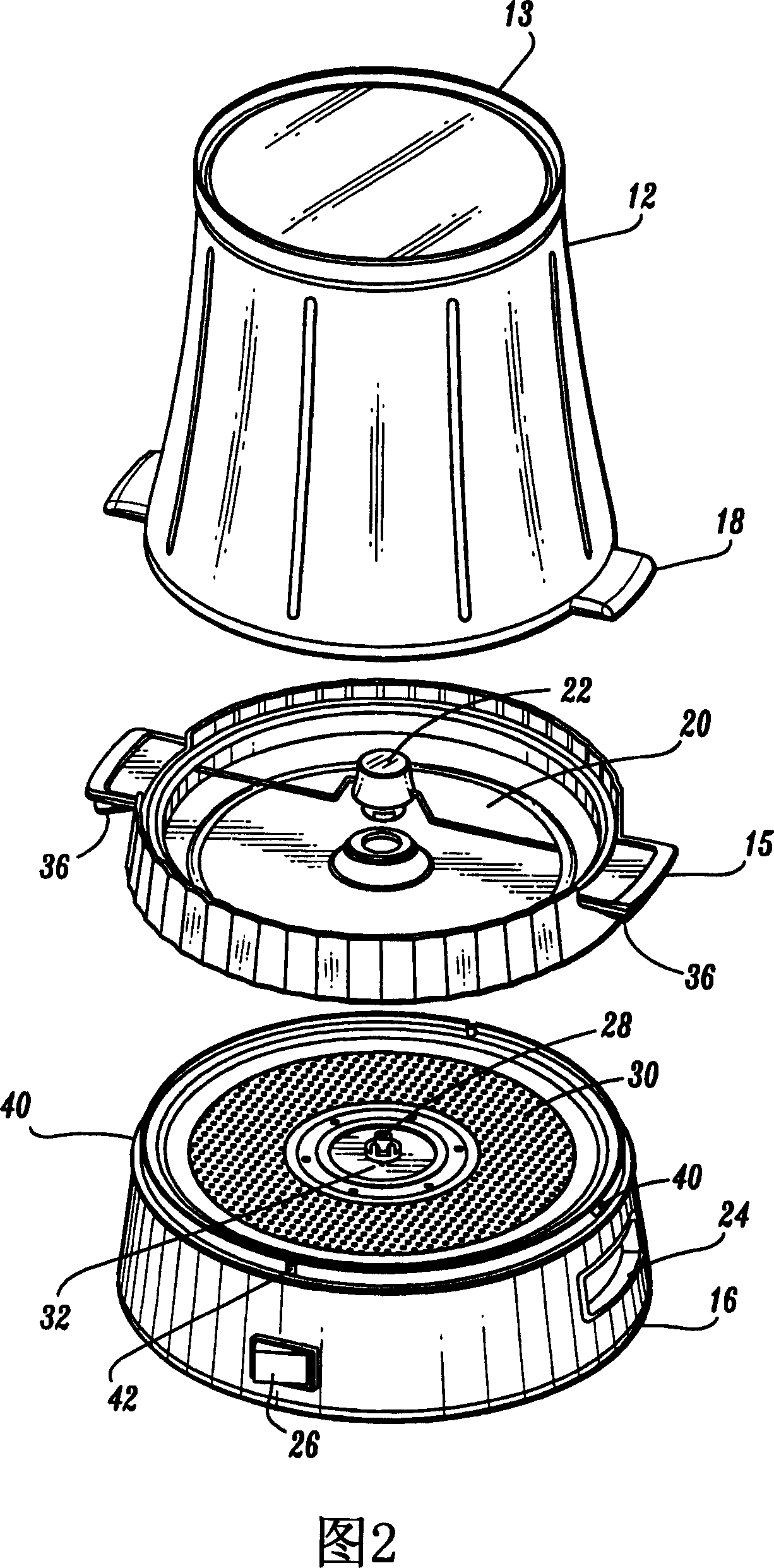

[0012] FIG. 2 shows an exploded view of popcorn processor 10 . The container 12 is used to hold the corn kernels during the processing stage of the corn kernels, and can serve as a container for popcorn during the process of enjoying the popcorn. Container 12 may be made of plastic or other material sufficient to contain popcorn and withstand the heat necessary during processing of the grains. The top of the container 12 is provided with a raised flange 13 . The raised flange 13 helps prevent overheating and cold shrinkage from affecting the counter or table top. Container 12 is preferably transparent so that a user can see the grain during its processing. Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com