Winter-heating water circulating pump energy-saving control method

An energy-saving control and water circulation pump technology, applied in the field of electronics and control, can solve problems such as excessive heating, high temperature at the user end, energy waste, etc., and achieve the effect of large energy-saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

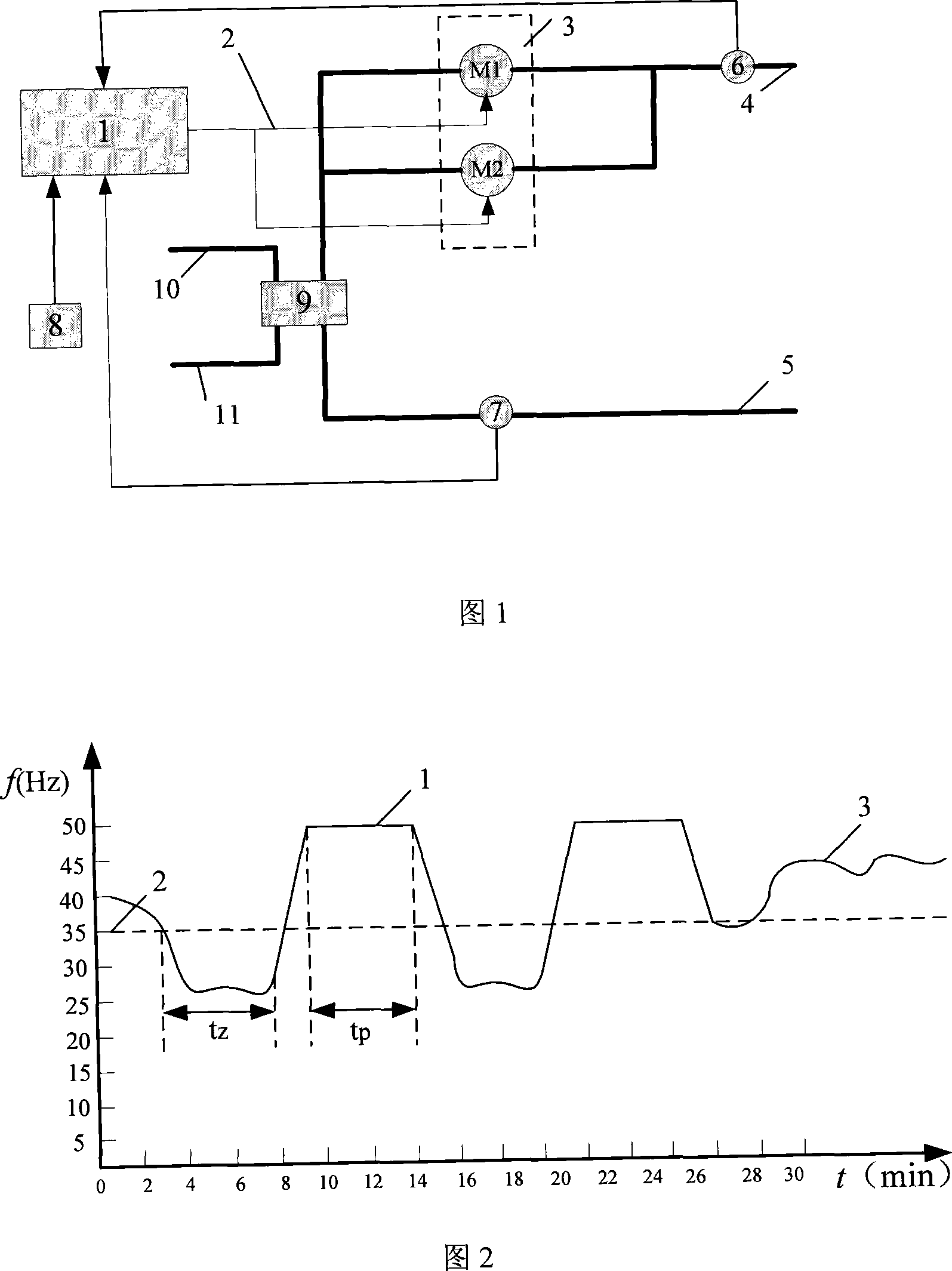

Embodiment 1

[0018] Embodiment 1: The present invention is applied to the energy-saving control of the water supply circulation pump of the secondary network of the heat pump station in the residential area. The control structure diagram is shown in FIG. 1 . The outdoor temperature is divided into three temperature ranges, the high temperature range is above -5°C, the low temperature range is below -20°C, and the middle temperature range is between the two temperatures. The upper and lower limits of the pulse frequency of each temperature section need to be set separately. The upper and lower limits of the pulse frequency of the low temperature section are set to 50Hz and 30Hz respectively; Set as 40Hz and 25Hz, as shown in Figure 4. In this example, the PWM pulse width modulation method is adopted, and the corner frequency (35Hz) and corner delay (2 minutes) must be preset. (1) Two temperature sensors (6 and 7 in Figure 1) transmit the measured temperature of the outlet pipe and the retu...

Embodiment 2

[0019] Embodiment 2: Apply the present invention to the energy-saving control of boiler heating and hot water circulation in winter in large-scale industries, enterprises or institutions. In this example, the outdoor temperature is divided into three temperature ranges, the high temperature range is above -6°C, the low temperature range is below -22°C, and the middle temperature range is between the two temperatures. The upper and lower limits of the pulse frequency of each temperature section need to be set separately. The upper and lower limits of the pulse frequency of the low temperature section are set to 50Hz and 32Hz respectively; Set as 42Hz and 25Hz, as shown in Figure 4. In this example, the PWM pulse width modulation method is adopted, and the corner frequency (32Hz) and corner delay (2 minutes) must be preset. (1) Two temperature sensors (6 and 7 in Figure 1) transmit the measured temperature of the outlet pipe and the return pipe to the energy-saving control cabi...

Embodiment 3

[0020] Embodiment 3: Apply the present invention to the energy-saving control of the central air-conditioning hot water cycle with cooling and heating cycle in the intelligent building. In this example, the outdoor temperature is divided into three temperature ranges, the high temperature range is above -5°C, the low temperature range is below -20°C, and the middle temperature range is between the two temperatures. The upper and lower limits of the pulse frequency of each temperature section need to be set separately. The upper and lower limits of the pulse frequency of the low temperature section are set to 50Hz and 35Hz respectively; Set as 40Hz and 25Hz, as shown in Figure 4. In this example, the PWM pulse width modulation method is used, and the corner frequency (30 Hz) and corner delay (2 minutes) must be preset. (1) Two temperature sensors (6 and 7 in Figure 1) transmit the measured temperature of the outlet pipe and the return pipe to the energy-saving control cabinet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com