Bag-holding structure of air-bag tension holding type for valve mouth balance

A bag structure and air bag technology, which is applied in the field of air bag expansion-holding bag holding structure, can solve the problems of surface damage and rupture of flexible material packaging bags, reduced packaging bag volume, and deformation of packaging bag mouths, so as to eliminate the phenomenon of powder spraying. , Guarantee the effect of sealing, material waste and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

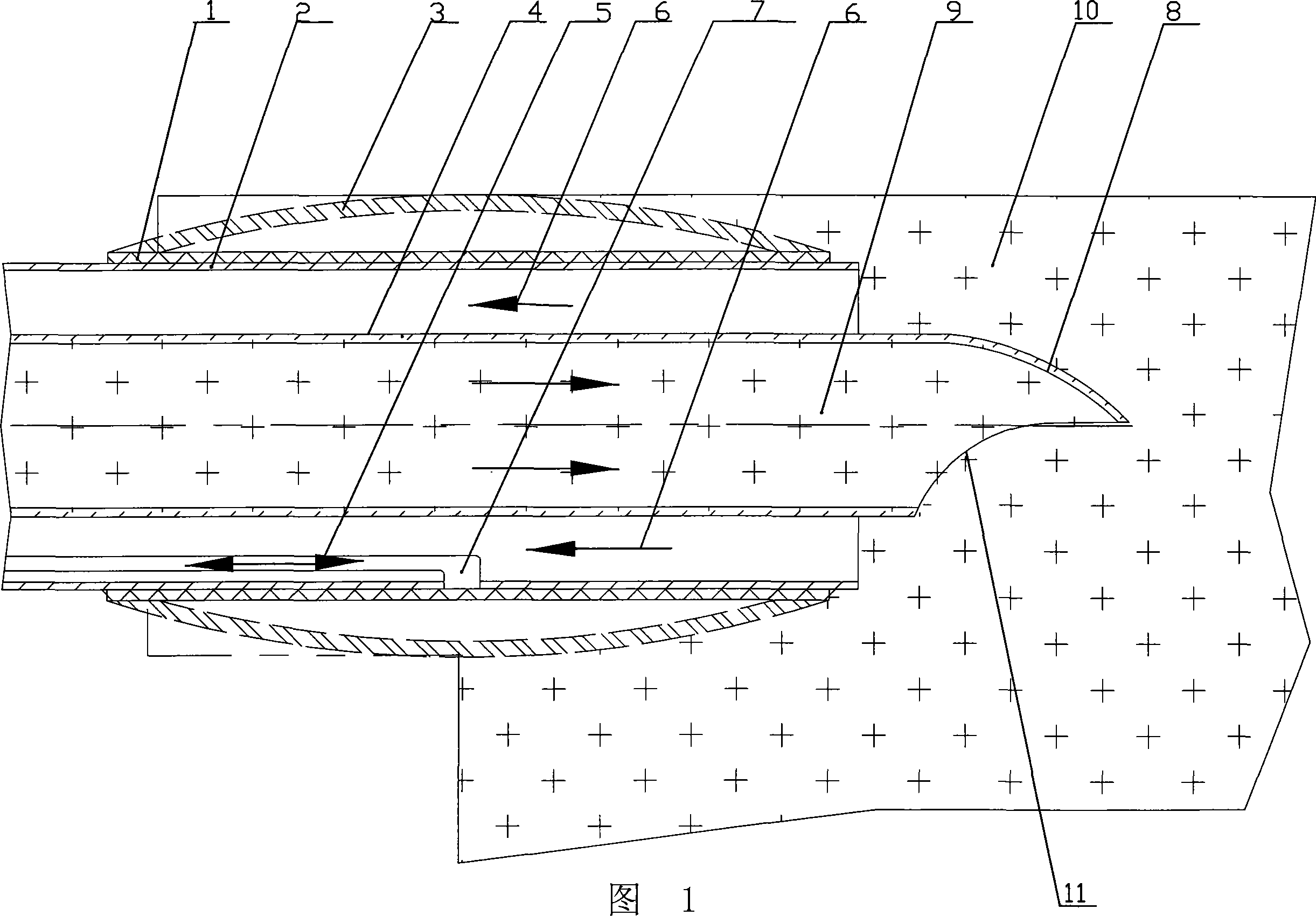

[0008] In the figure: 1. Air bag, 2. Exhaust outer tube, 3. Air bag when inflated, 4. Discharge nozzle, 5. Inflated air flow, 6. Exhaust channel, 7. Air bag trachea, 8. Curved wall, 9, material, 10, valve pocket, 11, arc opening,

[0009] There is an exhaust outer pipe 2 outside the discharge nozzle 4, an exhaust passage 6 is formed between the discharge nozzle 4 and the exhaust outer pipe 2, and an air bag 1 is arranged outside the exhaust outer pipe 2, and the air bag 1 The two ends of the two ends are sealingly connected to the outside of the exhaust outer tube 2, and a trachea 7 for inflating the air bag 1 is arranged on the exhaust outer tube 2 corresponding to the air bag 1.

[0010] The outlet shape of the discharge nozzle 4 is: the upper wall is a downward curved arc wall 8, the outer end of the arc wall 8 is close to the center line of the discharge nozzle 4, and the lower part is an open arc opening 11. The structure helps the material to enter the valve pocket 10 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com