Flexible plate rubber dam

A technology of rubber and dams, applied in sea area engineering, coastline protection, layered products, etc., can solve problems such as reinforcement layer degradation, metal surface rust, and reduce protection characteristics, so as to achieve the effect of preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] With reference to the following drawings, the most preferred embodiment of the flexible rubber embankment of the present invention is described in detail.

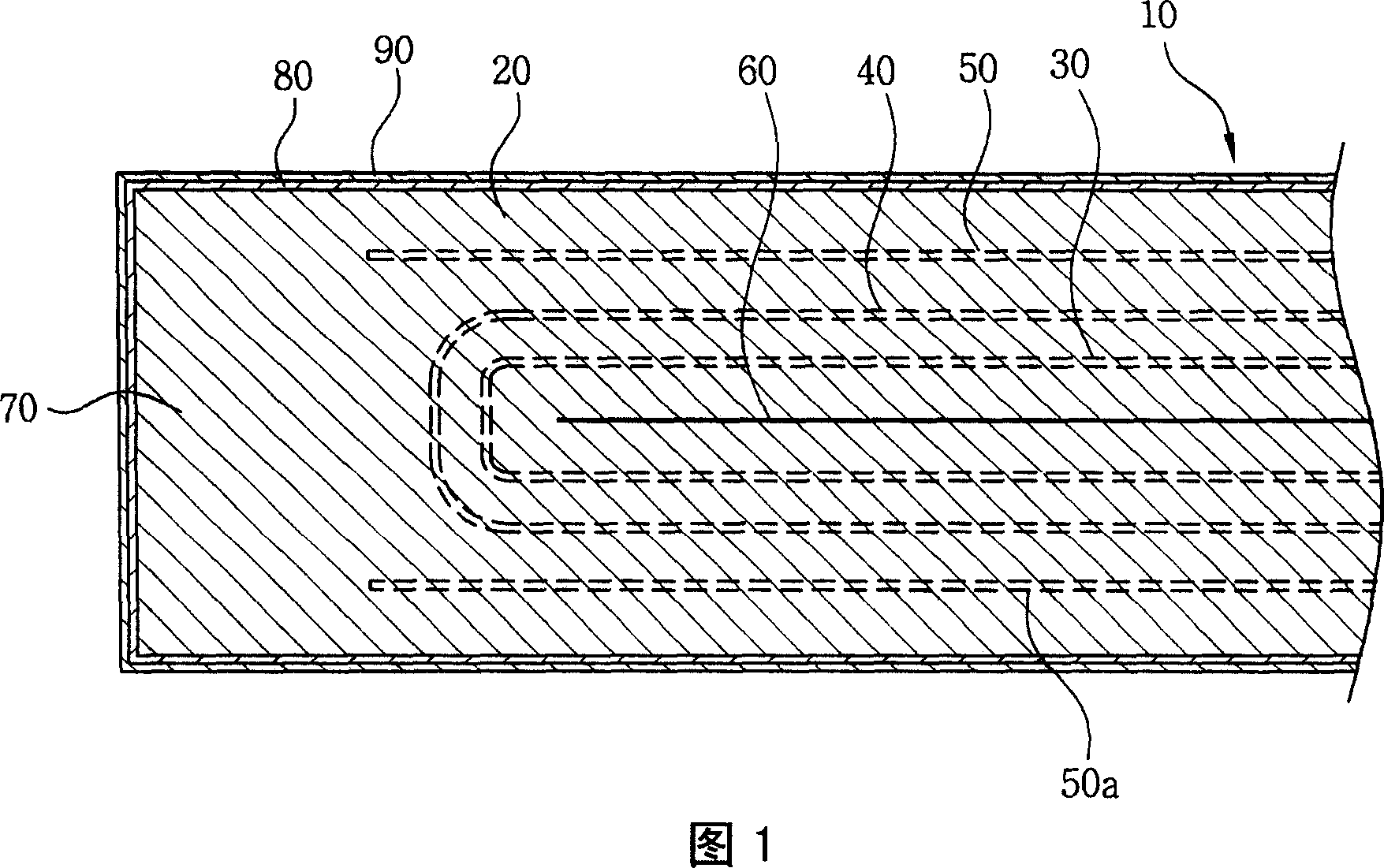

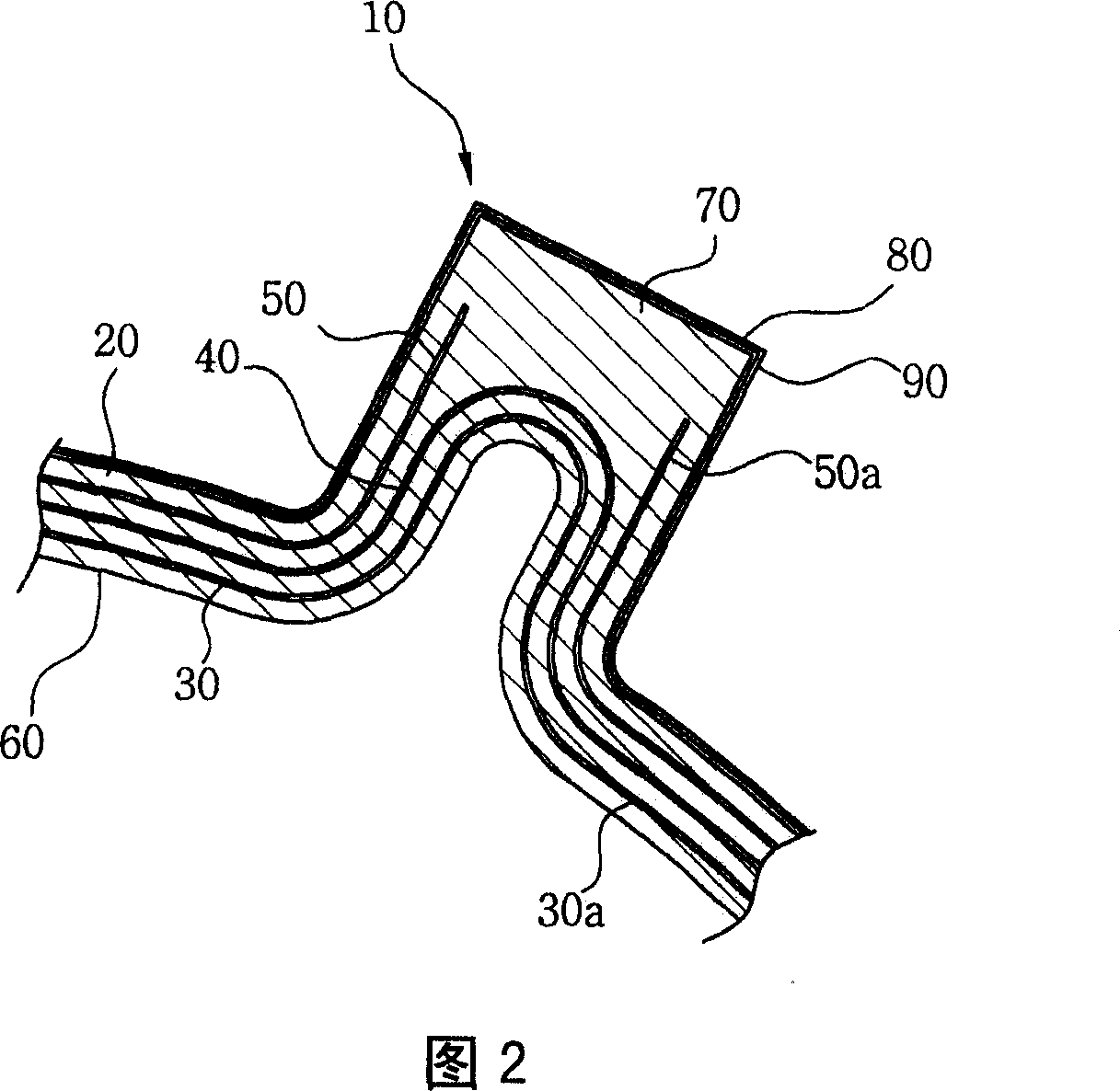

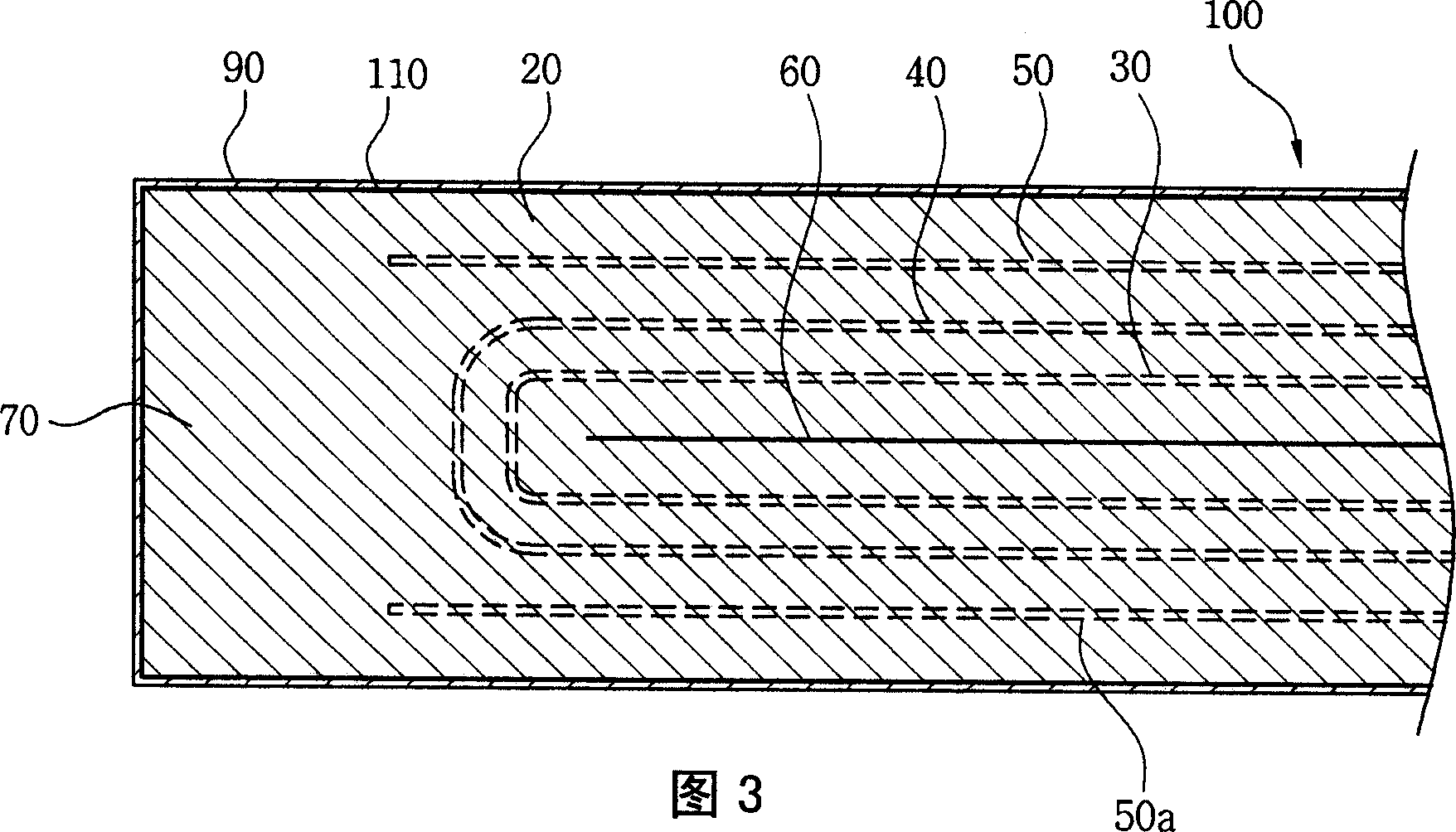

[0032] 1 is a partial cross-sectional view of a first embodiment of a flexible rubber embankment; FIG. 2 is an enlarged cross-sectional view of an added portion of the flexible rubber embankment of FIG. 1 in an upright state.

[0033] The rubber weir 10 constituting the rubber dam of the present invention is made of strip-shaped rubber sheet 20 .

[0034] The inner center of the rubber plate 20 is provided with a free section of the partition 60 that can be discharged upwards and downwards; The downward fold provides the addition 70 protruding outward like the binding of a book.

[0035] The first fiber-reinforced layer 30 and the second fiber-reinforced layer 40 are buried continuously and alternately along the upper and lower interiors of the rubber sheet 20 of the dischargeable partition 60 at the position surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com