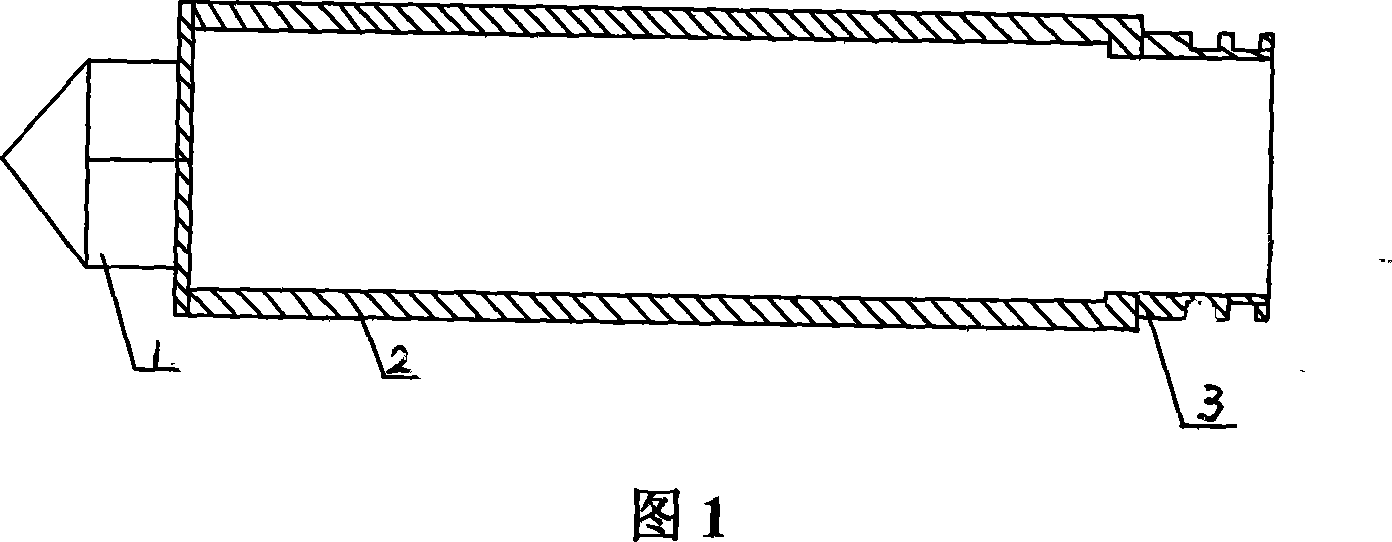

Wine rod type filter element and method for making same

A filter element and rod-type technology, which is applied in the field of filtration equipment, can solve the problems of unstable filtration accuracy, inability to backwash, and inability to regenerate, and achieve the effects of ensuring the appearance quality of finished products, increasing filtration time, and improving filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

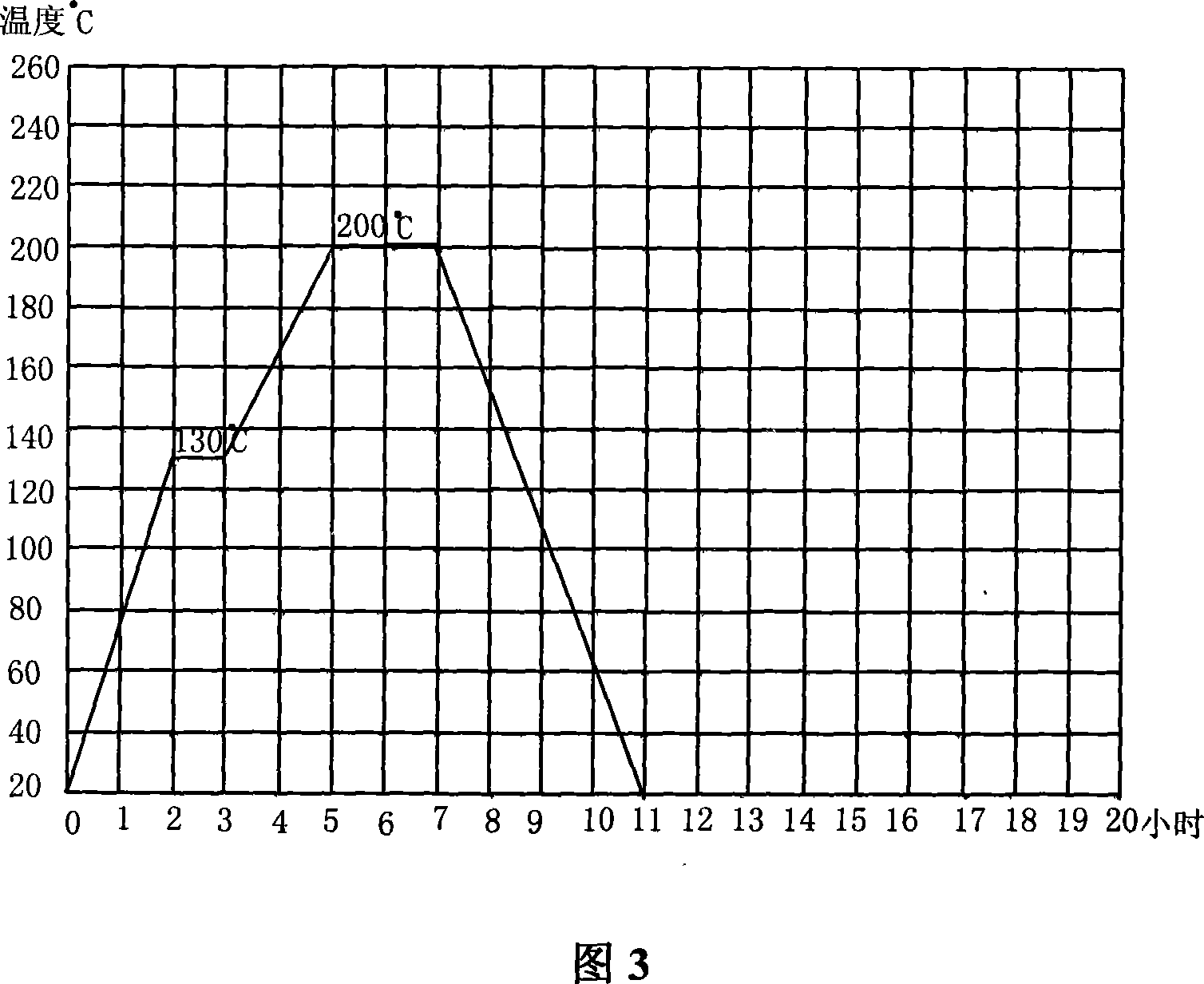

[0020] Prepare the rod filter element according to the following process steps:

[0021] First, according to the filter pore size requirements of the product to be obtained, use molecular sieves to screen out the required ultra-high molecular polyethylene or high-density polyethylene raw materials with different pore sizes. For example, to make a filter rod with a filter pore size of 0.2 μm, ultra-high molecular polyethylene or high-density polyethylene with a particle size of 60-400 mesh and a molecular weight of 1.5 million-3 million units can be selected. In addition, in order to enhance the uniformity of the filter pore diameter, 4-5% of auxiliary material polyfluorotetrachloroethylene can also be added, and the mold can be loaded after mixing and stirring evenly.

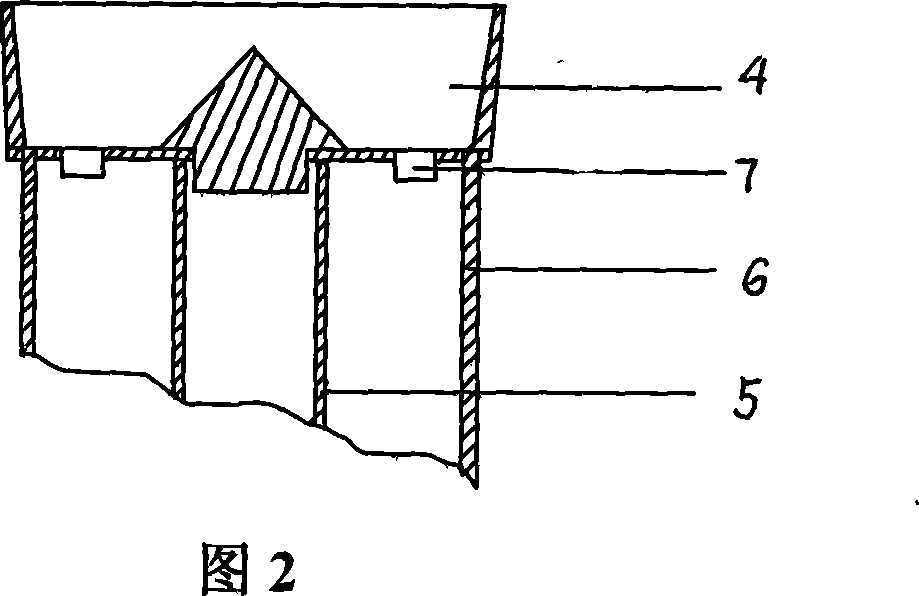

[0022] Then, the mold that usually makes hollow rods is used as the mold for making the rod filter layer. The mold is composed of an outer mold, an inner membrane, a base and an upper cover. In order to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com