Method of increasing speed of silver halide color photosensitive material

A silver halide, color light technology, applied in optics, multi-color photography process, photography process and other directions, can solve the problems of side effects, insufficient effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

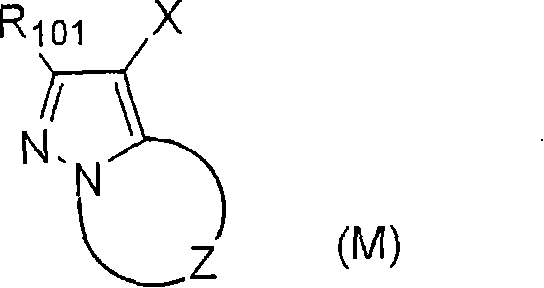

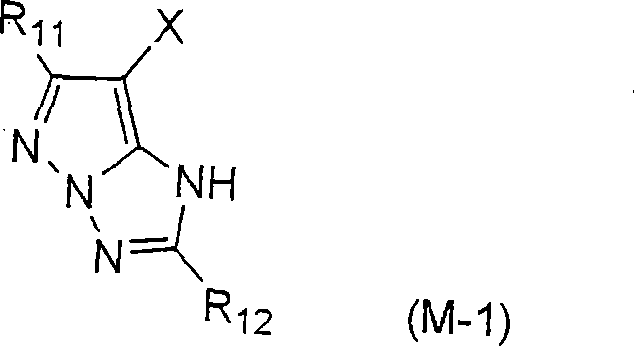

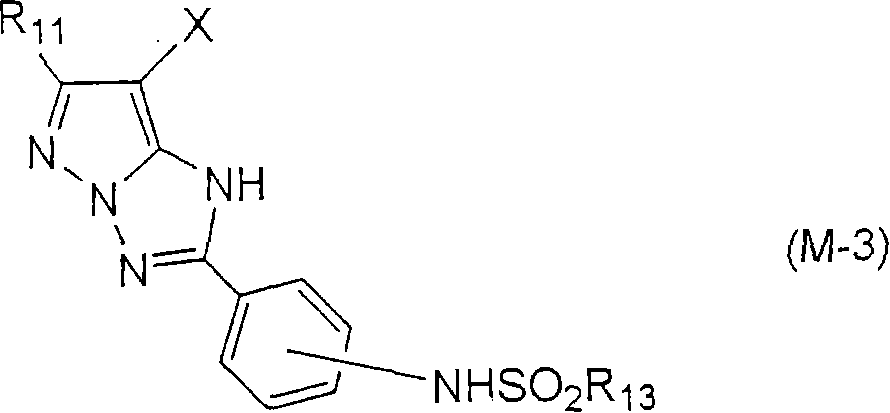

Method used

Image

Examples

Embodiment 1

[0262] The carrier used in this example was prepared as follows.

[0263] 1) First layer and subbase:

[0264] The polyethylene naphthalate carrier with a thickness of 90 μm on both surfaces was treated by the glow discharge method, and the treatment conditions were: the ambient pressure was 2.66×10Pa, H 2 The O partial pressure is 75% of the ambient pressure, the discharge frequency is 30kHz, the output is 2500W, and the processing intensity is 0.5kV·A·min / m 2 . The carrier uses a coating solution with the following composition, and the coating amount is 5mL / m 2 , applied according to the rod coating method described in JP-B-58-4589 to produce the first layer.

[0265] Conductive fine particle dispersion (SnO 2 / Sb 2 o 5 Granules 10% Concentration

[0266] Aqueous dispersion, primary particles with an average particle size of 0.005 μm

[0267] Secondary agglomerates, the particle size of which is 0.05 μm) 50 parts by weight

[0268] Gelatin 0.5 parts by weight

[02...

Embodiment 2

[0712] Sample 201 was prepared in the same manner as Sample 106, but the compound (56) described in Example 1 for the 11th layer of Sample 106 was moved into the 12th layer.

[0713] As with sample 106, sample 201 was evaluated using the method described in Example 1. The increase value of the sensitivity rate of the green sensitive layer is 0.03, which is reduced compared with 0.06 of the sample 106. However, before the preparation of sample 201, after the coating solutions of the 11th and 12th layers were placed at 40°C for 12 hours, the phenomenon of increased fog did not appear in sample 201, thus making sample 201 overcome the problem in the 11th layer of sample 106. The disadvantage of an increase in undesired fogging occurs.

[0714] From the viewpoint of increasing the effect, it is preferable to directly add the compound of the present invention to the photosensitive layer. However, from the viewpoint of preventing the above-mentioned side effects, it has been found...

Embodiment 3

[0716] The carrier used in Example 3 was prepared by the same method as in Example 1.

[0717] Apply photosensitive layer by coating

[0718] Next, on the opposite side of the obtained back layer support, coating was performed with a plurality of layers each having the following composition, whereby a color negative film sample 301 was obtained.

[0719] (Composition of photosensitive layer)

[0720] In addition to the description of each component, the given value expresses the coating amount in g / m2. For silver halide, coating weights are calculated in terms of silver.

[0721] The use of numbers is the same as in Example 1 for each specific compound.

[0722] (Sample 301)

[0723] The first layer (the first anti-halation layer)

[0724] Vinyl Silver Silver 0.104

[0725] Silver iodobromide emulsion grains with an average grain diameter of 0.07 μm Silver 0.011

[0726] Gelatin 0.910

[0727] ExM-1 0.060

[0728] ExC-1 0.002

[0729] ExC-3 0.002

[0730] Cpd-2 0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com