Method of catalytically synthesizing alpha-monolinolenin by using immobilization lipase

A technology for immobilizing lipase and linolenic acid monoglyceride, which is applied in the direction of being fixed on/in an organic carrier, can solve the problem of hindering the wide application of α-linolenic acid monoglyceride, excessive organic solvent residues in medicine, extraction It can solve the problems of difficult purification and other problems, so as to achieve the effect of easy continuous production, large-scale industrial production and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

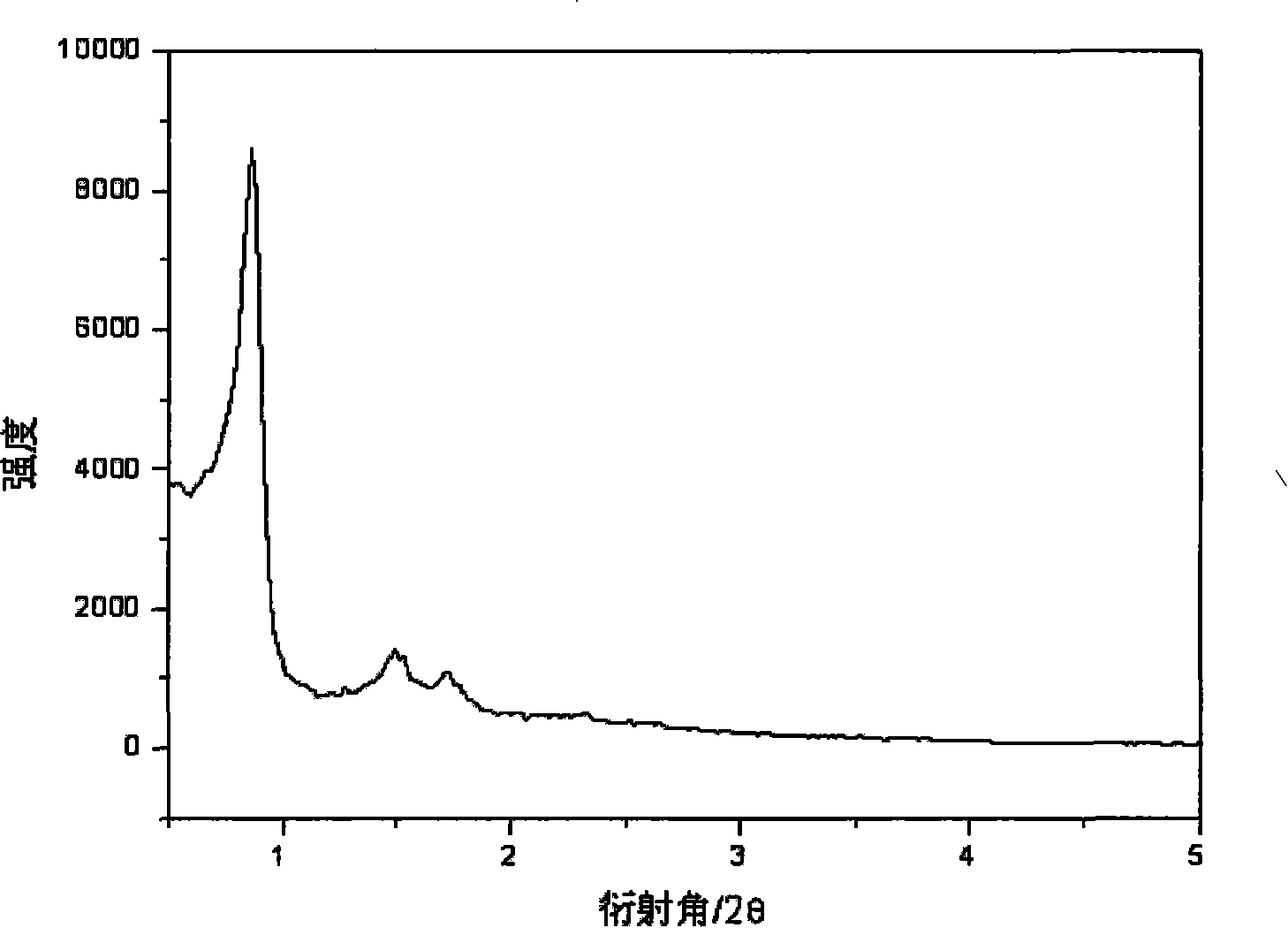

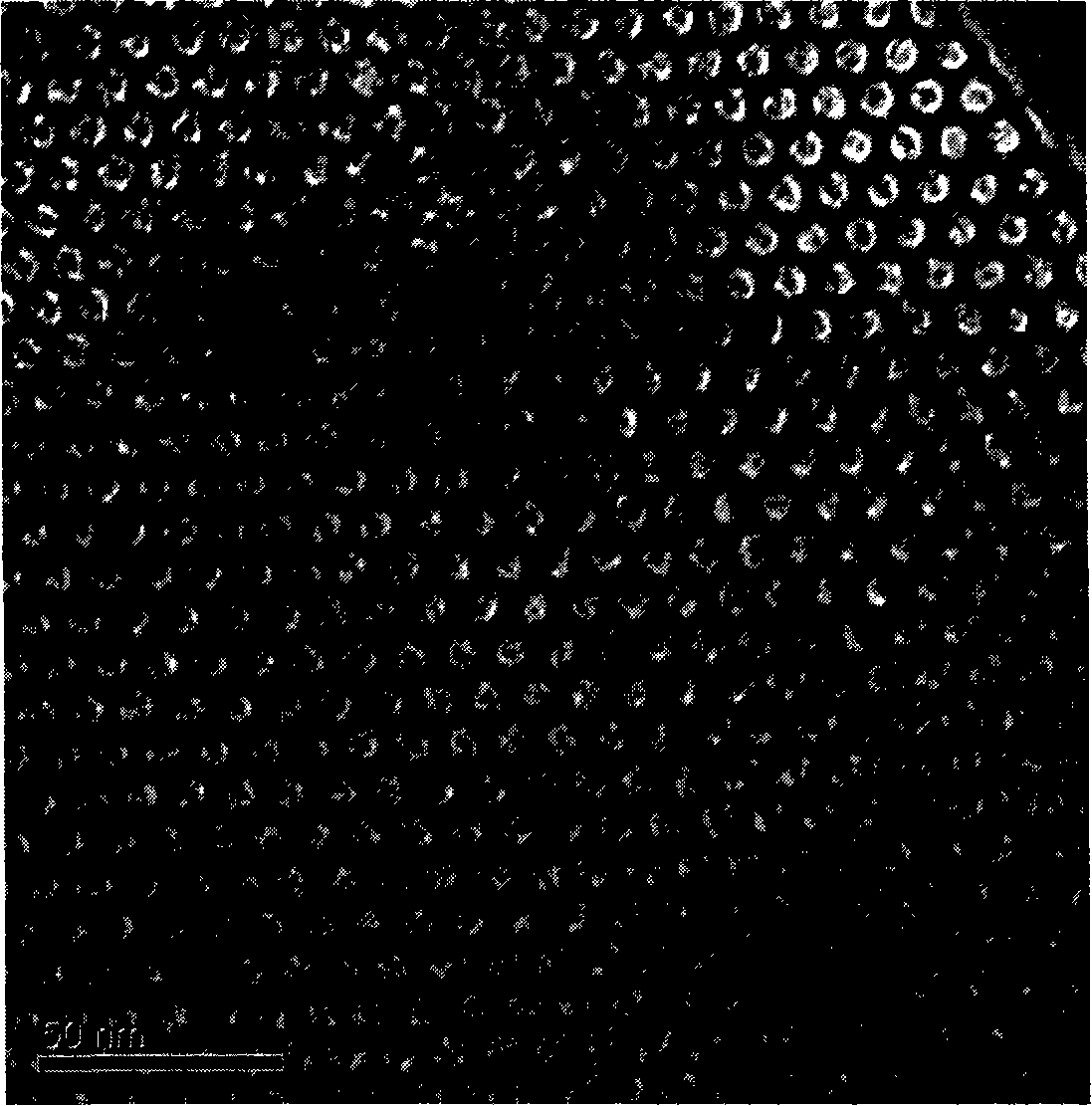

[0027] Example 1 Pore expansion modification and characterization of mesoporous material SBA-15

[0028] Dissolve 0.8 g of the triblock copolymer compound P123 (Pluronic P123) in deionized water, add it into hydrochloric acid after the P123 is completely dissolved, and stir to dissolve. The mixture was stirred at a constant temperature of 50° C. to 60° C. for 30 to 45 minutes, then 3 ml of ethanol was added, stirred, put into a reaction kettle, and placed in an oven at 100° C. for 48 hours. The product was filtered, washed and dried. Then burn at 500°C-550°C for 6-8 hours to completely remove the surfactant. The product name is: SBA-15 / 80.

[0029] The mesoporous material SBA-15 / 80 was dissolved in deionized water with a mass:volume ratio of 1g:30ml, heated to reflux for 3.5h, the mixture was cooled and centrifuged to remove water, and the white solid was dried in air for 6 days. Take the hydrated mesoporous material and add 130ml of toluene and 15ml of APTES successively, ...

Embodiment 2

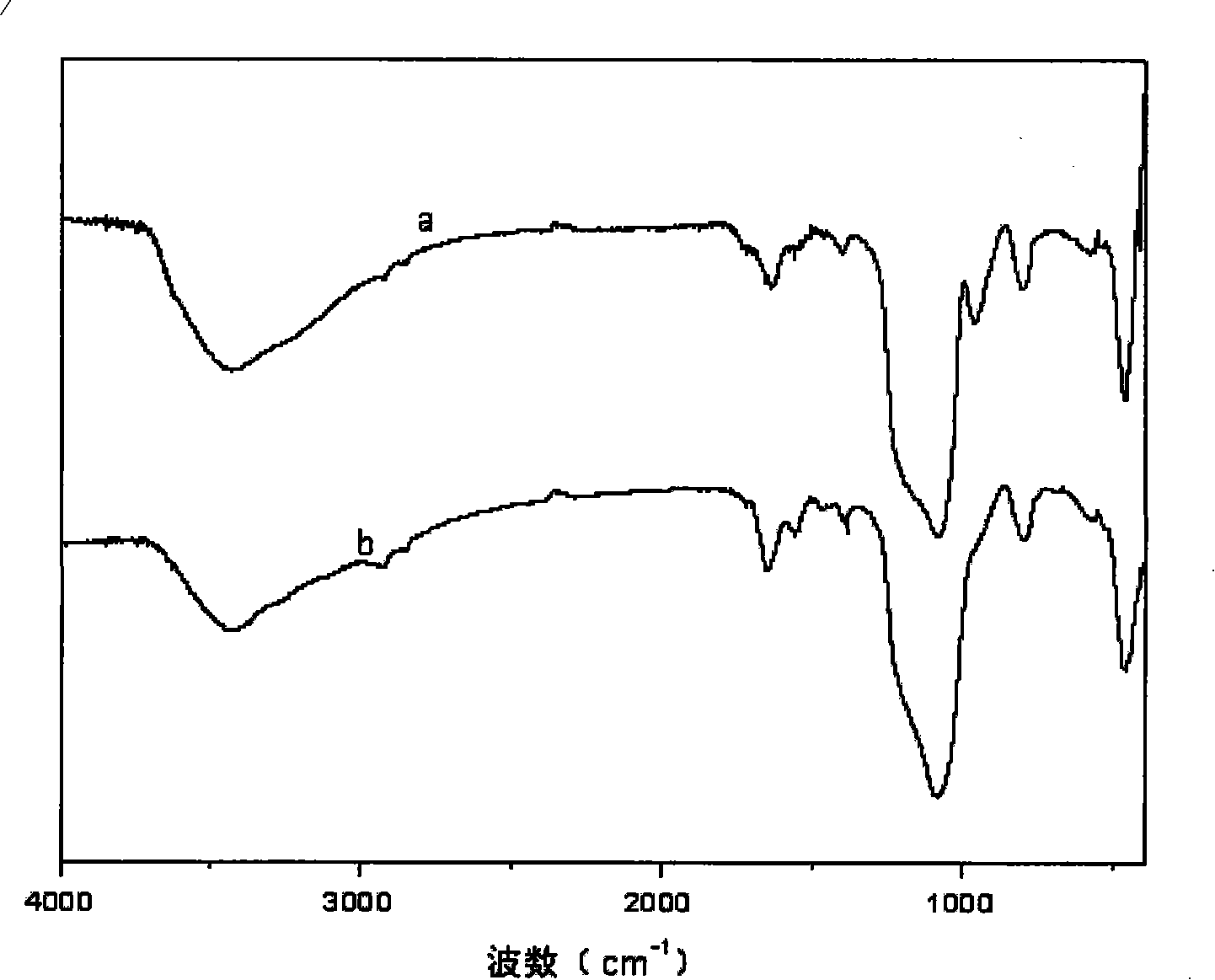

[0036] The assembly of embodiment 2 immobilized lipase and determination of its optimum conditions

[0037] Get the mesoporous material NH that embodiment 1 makes 2 -SBA-15 / 80 and glutaraldehyde, mass:volume ratio 1g:30ml, reacted for 3h under stirring, then washed with phosphate buffer to remove unreacted glutaraldehyde. Add 30ml Candida lipase solution to the mesoporous material and react for 5 hours, finally wash with PBS and centrifuge (5000rpm, 13min) until no protein can be detected in the solution.

[0038] In this example, the Candida lipase was replaced by Pseudomonas aeruginosa lipase, the usage is the same, and the effect of the two is also the same.

[0039] For the optimum temperature of immobilized lipase, the optimum pH, the determination of the Michaelis constant (Km) and the thermal stability, see the attached Figure 5-8 .

[0040] Figure 5 It shows the change of optimum temperature before and after lipase immobilization, that is, after the enzyme is imm...

Embodiment 3

[0045] Example 3 Synthesis of α-linolenic acid monoglyceride in organic phase by immobilized enzyme

[0046] Take 1 g of the immobilized enzyme synthesized in Example 2, add the organic solvent n-hexane, and stir evenly. Add linolenic acid and glycerin (20ml each), and the initial concentrations are 25mmol / ml and 30.0mmol / ml respectively. The mixture was incubated in a constant temperature water bath shaker at 20-50°C for a certain period of time. Finally, the reaction mixture was filtered to remove the immobilized enzyme, and n-hexane was evaporated under reduced pressure. The residue is the product alpha-linolenic acid monoglyceride, a coixenolide. Qualitatively and quantitatively determined by high-performance liquid chromatography, the yield is 75-80%.

[0047] In this embodiment, the organic solvent n-hexane can be replaced by ethyl acetate.

[0048] In this example, there is a slight increase or decrease in the amount of each raw material (as within the scope of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com