Oxidation resistance zymolyte rich in pollen active peptide

A technology of antioxidant enzymes and pollen activity, applied in the fields of peptides, food science, hydrolyzed protein components, etc., can solve the problems of poor food palatability and insignificant biological efficacy, and achieve the effects of high solubility, good application development prospects and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

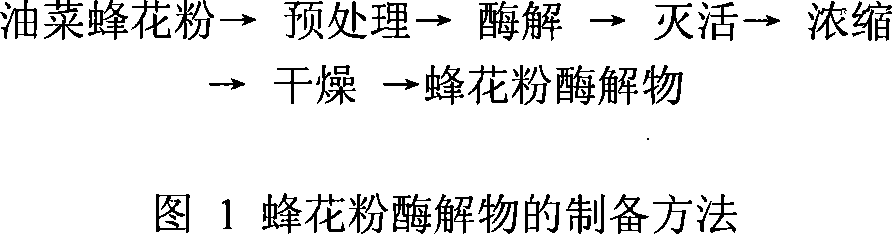

Method used

Image

Examples

Embodiment 1

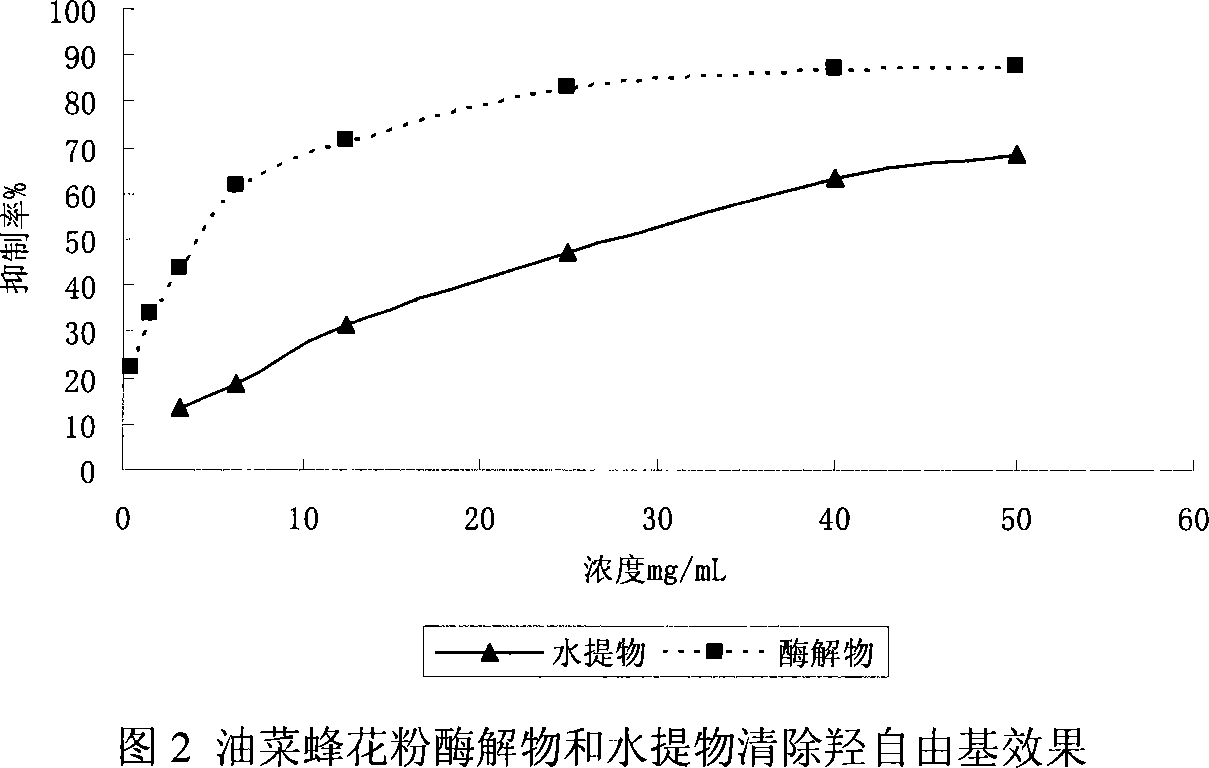

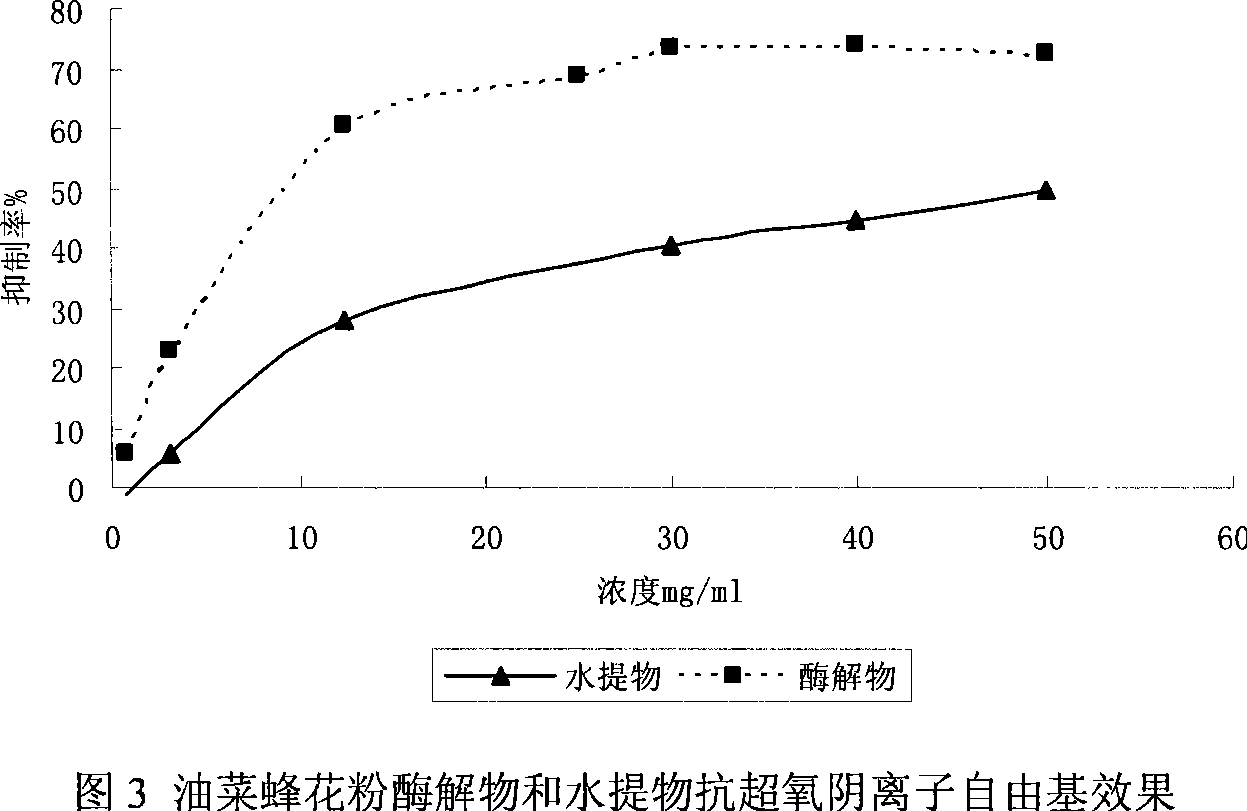

[0024] Preparation of enzymatic hydrolyzate: Weigh a certain amount of broken wall rape bee pollen, add it to the buffer system with a pH value of 9 at a ratio of material to water of 1:10, mix well, adjust the temperature to 50°C, Add alkaline protease to hydrolyze at 1500U / g. After reacting for 3 hours, inactivate the enzyme at 90°C for 10 minutes, centrifuge at 4000rpm for 15 minutes, remove macromolecular compounds such as proteins from the supernatant with an ultrafiltration membrane with a relative molecular weight cut-off > 10000 D, and filter the membrane permeated part (that is, the small molecular compound part) with a cut-off filter. The ultrafiltration or nanofiltration membrane with a relative molecular weight <400D removes monosaccharides, amino acids, ionic components, etc., and the filtrate is freeze-dried. After testing, after rape bee pollen was hydrolyzed by alkaline protease and membrane separated, the content of free nitrogen in the water extract of the or...

Embodiment 2

[0026] Preparation of enzymatic hydrolyzate: Weigh a certain amount of broken wall rape bee pollen, add it to the buffer system with a pH value of 6.5 at a material-to-water ratio of 1:10, mix well, adjust the temperature to 50°C, and set the ratio of enzyme to substrate concentration as Add papain at 10000U / g for hydrolysis. After reacting for 3 hours, inactivate the enzyme at 90°C for 10 minutes, centrifuge at 4000rpm for 15 minutes, remove macromolecular compounds such as proteins from the supernatant with an ultrafiltration membrane with a relative molecular weight cut-off > 10000 D, and filter the membrane permeated part (that is, the small molecular compound part) with a cut-off filter. The ultrafiltration or nanofiltration membrane with a relative molecular weight <400D removes monosaccharides, amino acids, ionic components, etc., and the filtrate is freeze-dried.

Embodiment 3

[0028] Preparation of enzymatic hydrolyzate: Weigh a certain amount of broken wall rape bee pollen, add it to the buffer system with a pH value of 7 at a material-to-water ratio of 1:10, mix well, adjust the temperature to 40°C, and adjust the concentration ratio of enzyme to substrate to 800U / g Add neutral protease for hydrolysis. After reacting for 3 hours, inactivate the enzyme at 90°C for 10 minutes, centrifuge at 4000rpm for 15 minutes, remove macromolecular compounds such as proteins from the supernatant with an ultrafiltration membrane with a relative molecular weight cut-off > 10000 D, and filter the membrane permeated part (that is, the small molecular compound part) with a cut-off filter. The ultrafiltration or nanofiltration membrane with a relative molecular weight <400D removes monosaccharides, amino acids, ionic components, etc., and the filtrate is freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com