Alternating rotating direction honing cylinder jacket platform webbing technique

A technology of platform reticulation and rotation direction, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high engine oil consumption, affecting human health, and excessive exhaust emissions, shortening the overhaul period, and benefiting the environment. Protection and human health, the effect of increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

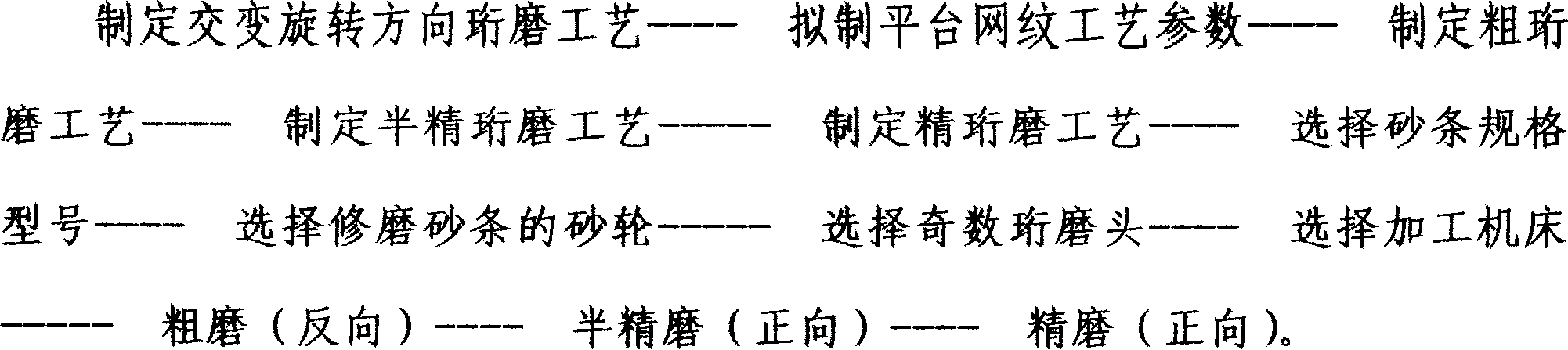

[0011] 1. Choose a reasonable process flow and processing method

[0012] The machining of the inner hole of the cylinder liner is completed by rough boring, fine boring and honing. The rough boring process mainly removes large machining allowances to provide reliable machining guarantee for subsequent fine boring. The fine boring process not only removes most of the machining allowance and ensures the uniformity and accuracy of the honing allowance, but more importantly, ensures the position accuracy of the inner hole of the cylinder liner and the shape tolerance such as the cylindricity of the inner hole, providing a good processing basis for the honing process .

[0013] The honing process is divided into three stages: rough honing, semi-finish honing and fine honing. In order to fully expose the graphite, the inner hole of the cylinder liner is processed in alternating directions of rotation. The boring tool rotates right when boring, the grinding head rotates left durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com