Working device and method for band-type blade

A processing method and blade technology, which is applied in the field of processing devices for strip-shaped blades, can solve problems such as the accuracy or shape error of strip-shaped blades, and achieve the effects of small precision and shape errors, and improved pass rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

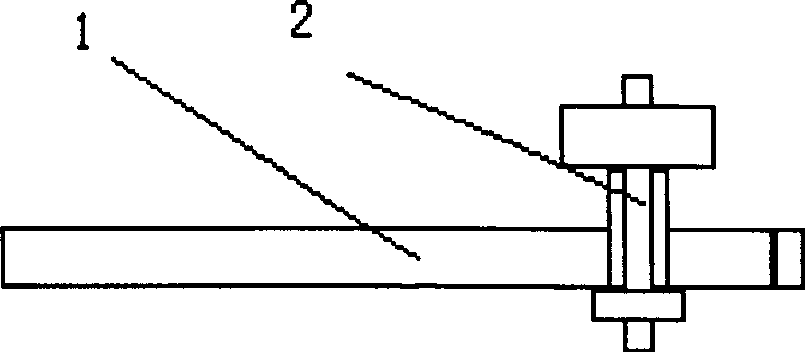

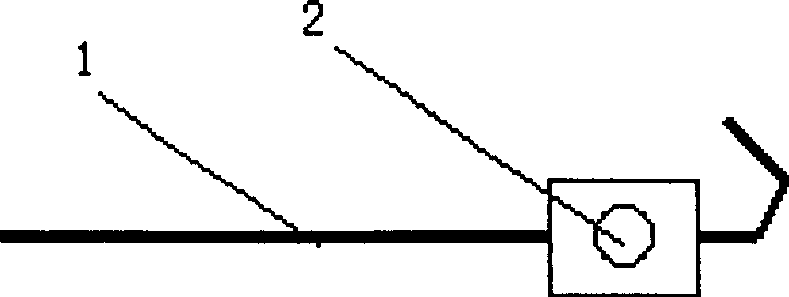

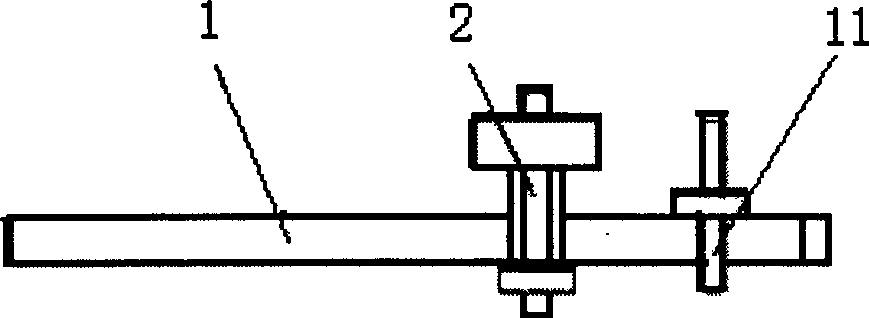

[0028] Such as Figure 7 , Figure 8 As shown, the processing device for strip-shaped blades of the present invention includes a first set of dies 3 , a bender 2 and a second set of dies 4 connected in sequence. The first set of dies 3 may be one or more die sets. Each die arrangement can have a different die shape 8 . Use one of them punching die device at every turn to punch out the precision notch 6 of required shape on the position of need on the top of strip blade 1, but the bottom end of strip blade 1 can not be punched off. The strip blade 1 can rely on the connection at the bottom to continue to advance and carry out follow-up work.

[0029] The second group of dies 4 breaks the bottom of the strip blade 1 to allow the strip blade 1 to carry out subsequent work; or punches the bottom of the strip blade 5 to separate the strip blade 5 from the strip blade 1 The strip-shaped blade 5 becomes a finished product.

[0030] according to Figure 7 , Figure 8 , the bar-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com