No contact energy-saving starter

A starter and non-contact technology, applied in the direction of motor generator/starter, single-phase induction motor starter, etc., can solve the problems of narrowing the scope of application, limitation of versatility, electromagnetic interference, etc., and achieve reliability Improve and reduce heating energy consumption, good starting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

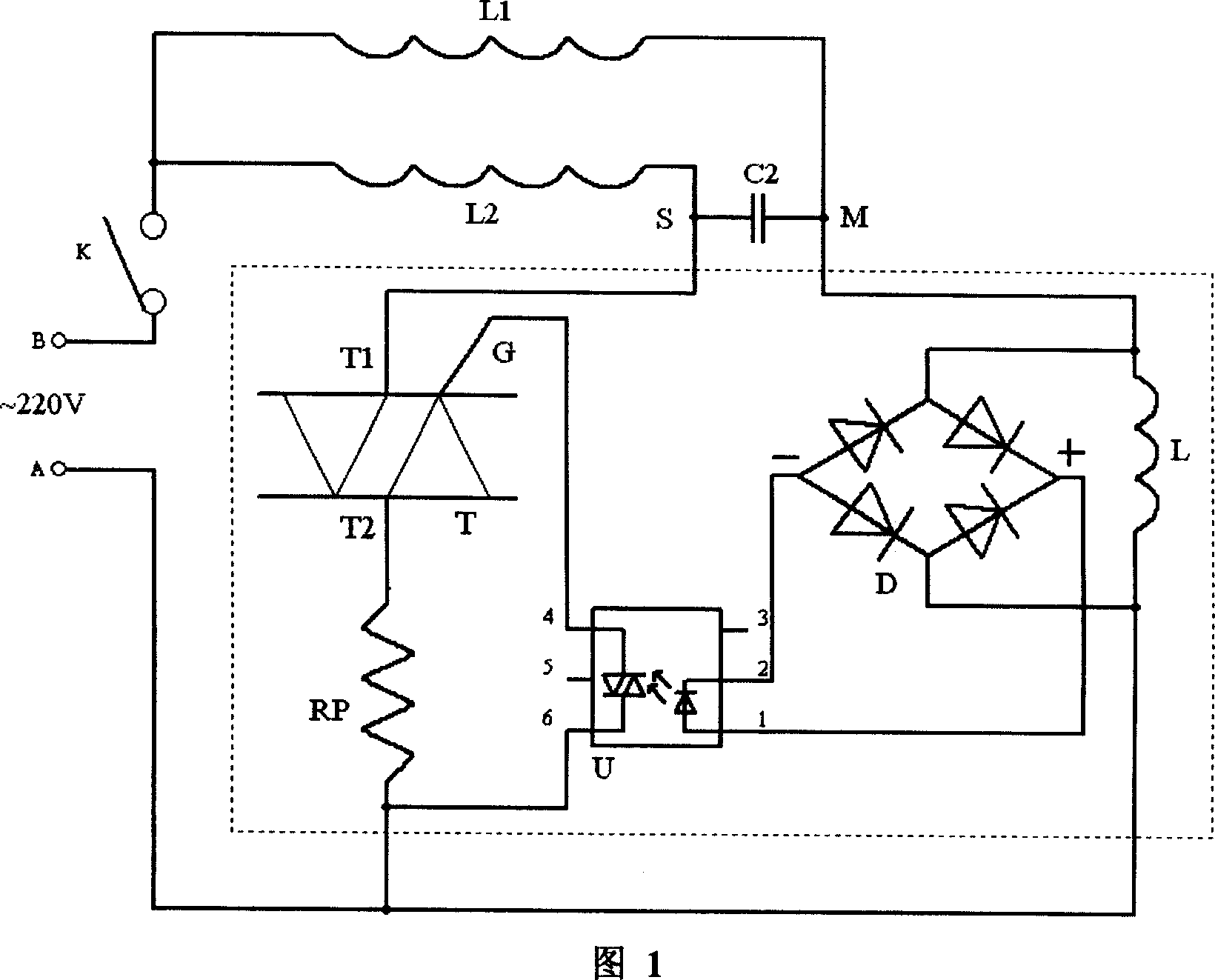

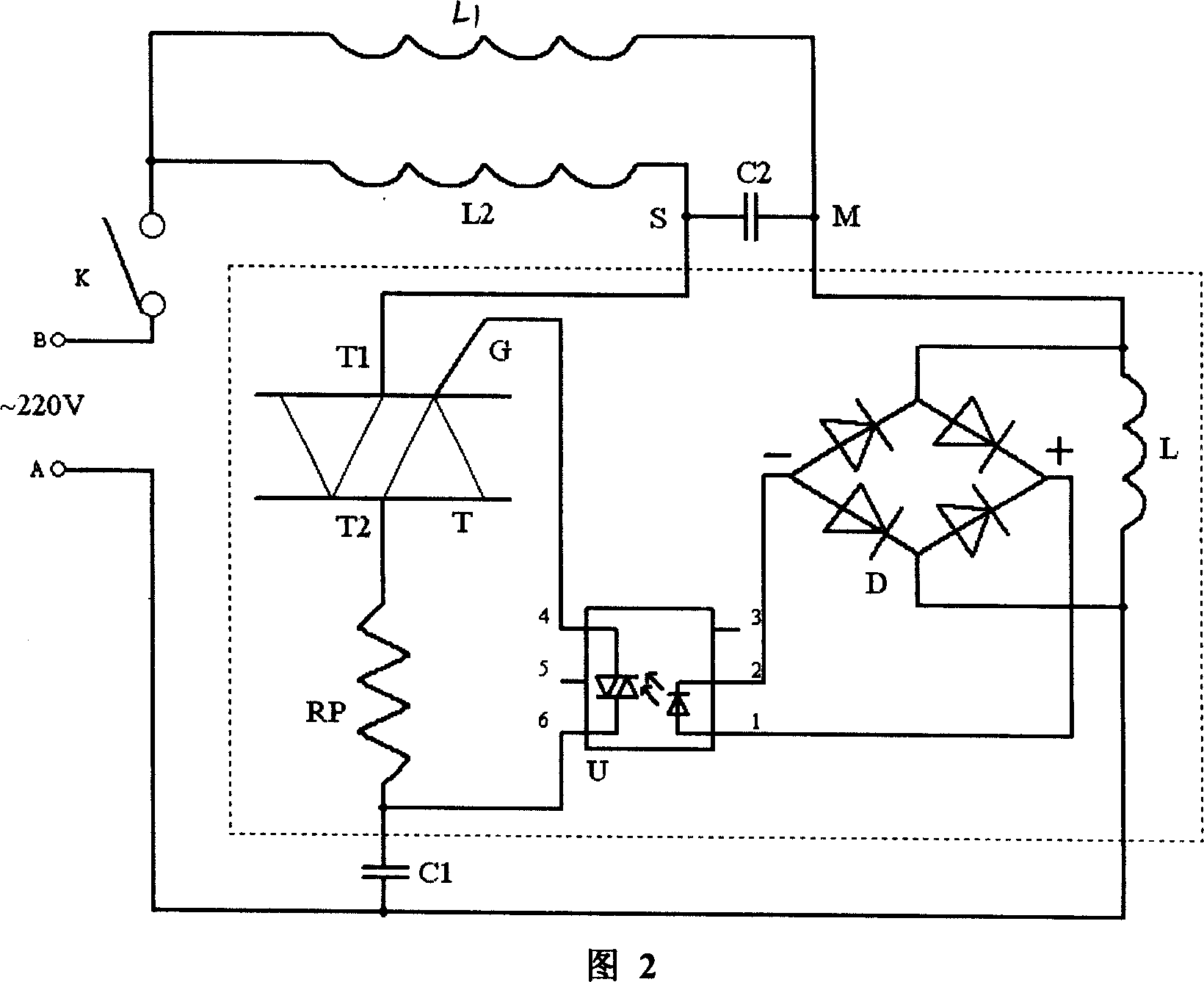

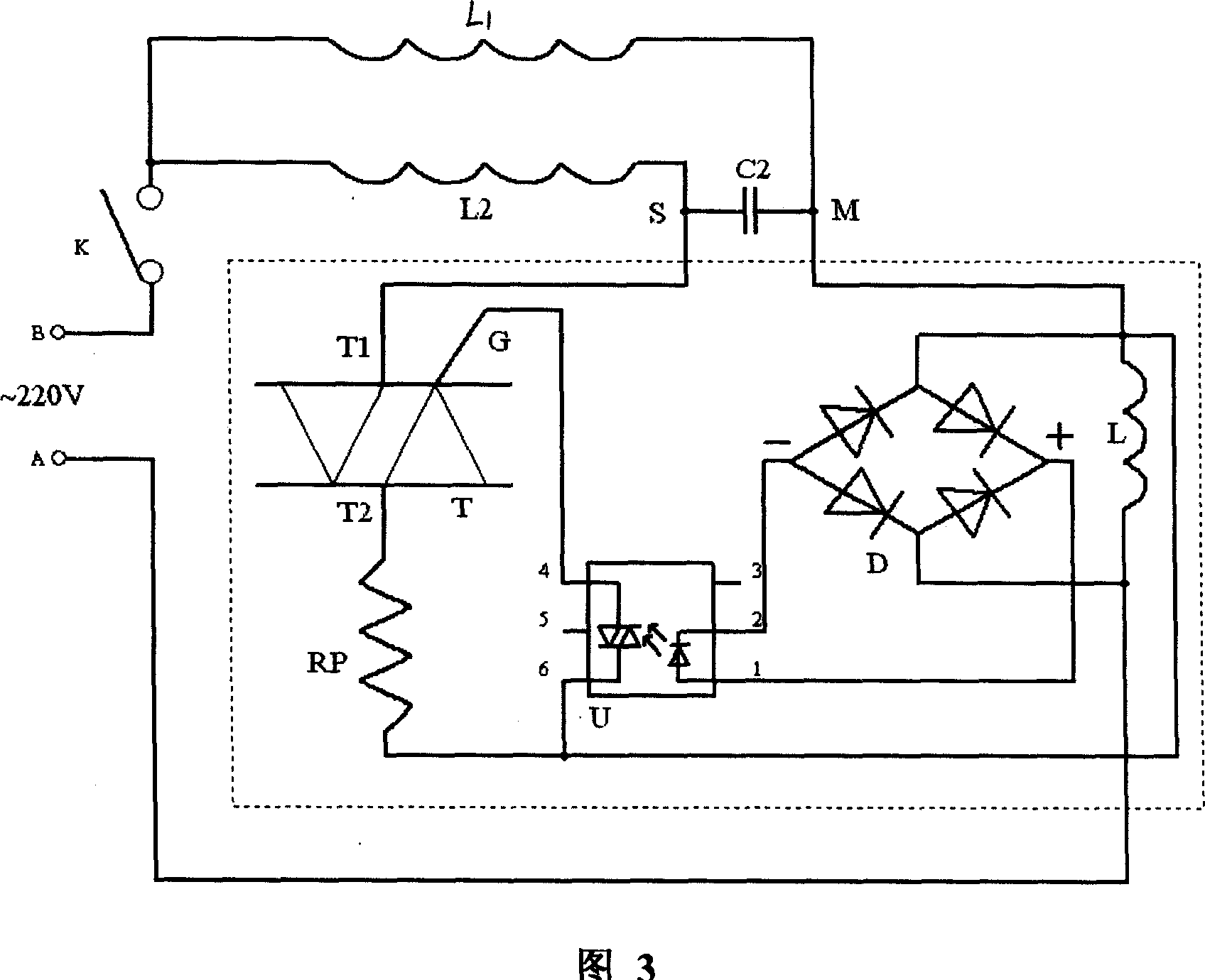

[0019] Shown in the dotted line box in the figure is a DC isolation control type non-contact energy-saving starter. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Referring to Fig. 1, the first embodiment of non-contact energy-saving starter, one electrode of PTC thermistor Rp and one output end (the 6th pin) of photoelectric coupler U are connected with AC power supply end A, PTC thermistor The other electrode of the device Rp is connected to the T2 pole of the triac T, and the other output terminal (pin 4) of the photocoupler U is connected to the G pole of the control terminal of the triac T. The T1 pole of the bidirectional thyristor T and one end of the run capacitor C2 are connected to the S end of the secondary coil L2 of the motor. One end of the inductor L, an AC input end of the rectifier bridge D, and the other end of the running capacitor C2 are connected to the M end of the main coil L1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com