Magnetic levitation reinforced concrete built pressing jet type wing-shape sail wind power generator

A reinforced concrete and wind turbine technology, which is applied in wind turbines, wind turbine combinations, and wind turbine control, etc., can solve the problem of difficulty in increasing the power generated by wind turbines, increasing the oncoming resistance of the sail surface, and three-dimensional space movement pollution. problem, to achieve the effect of eliminating mechanical processing, no ecological pollution, high-efficiency and high-power power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

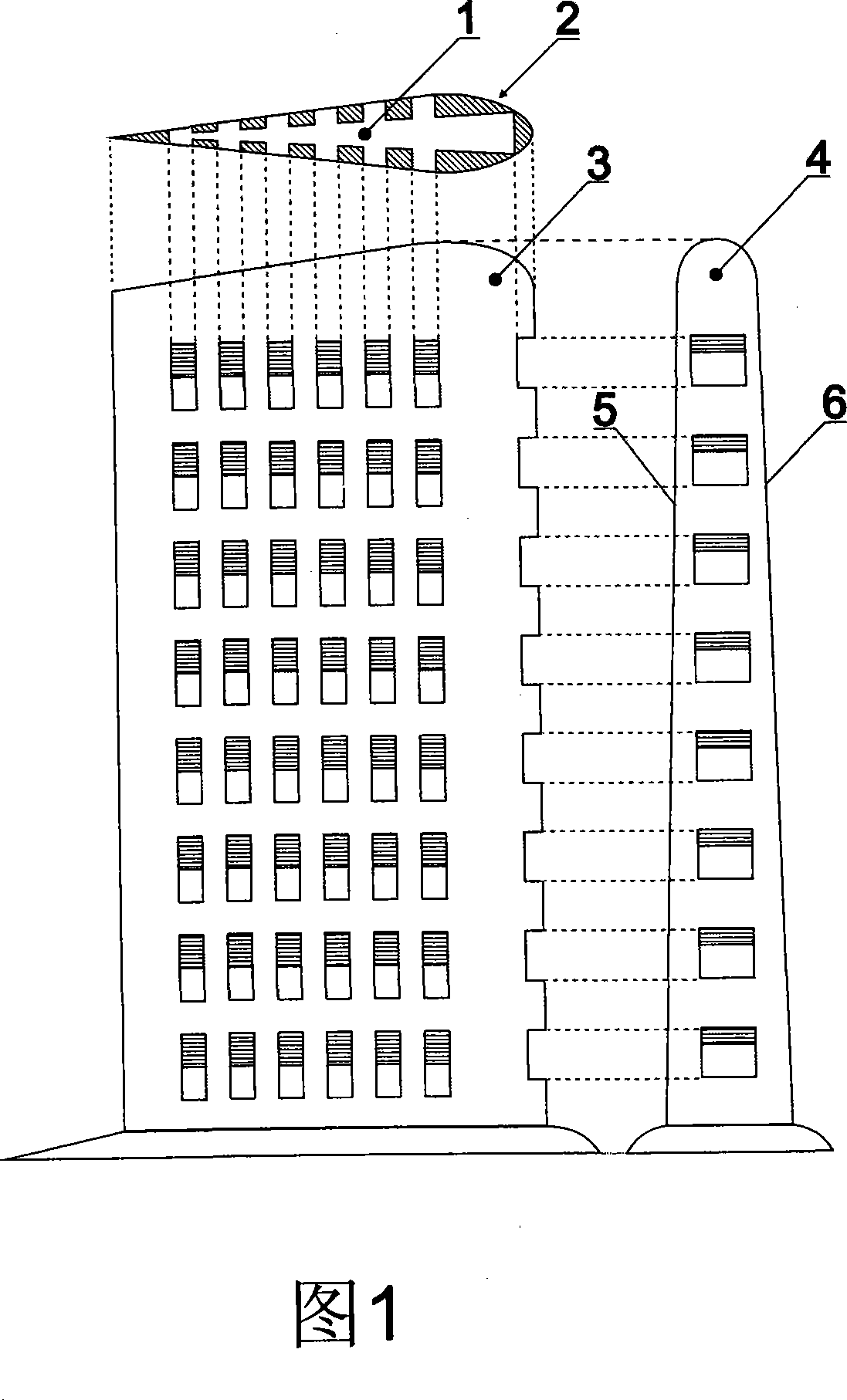

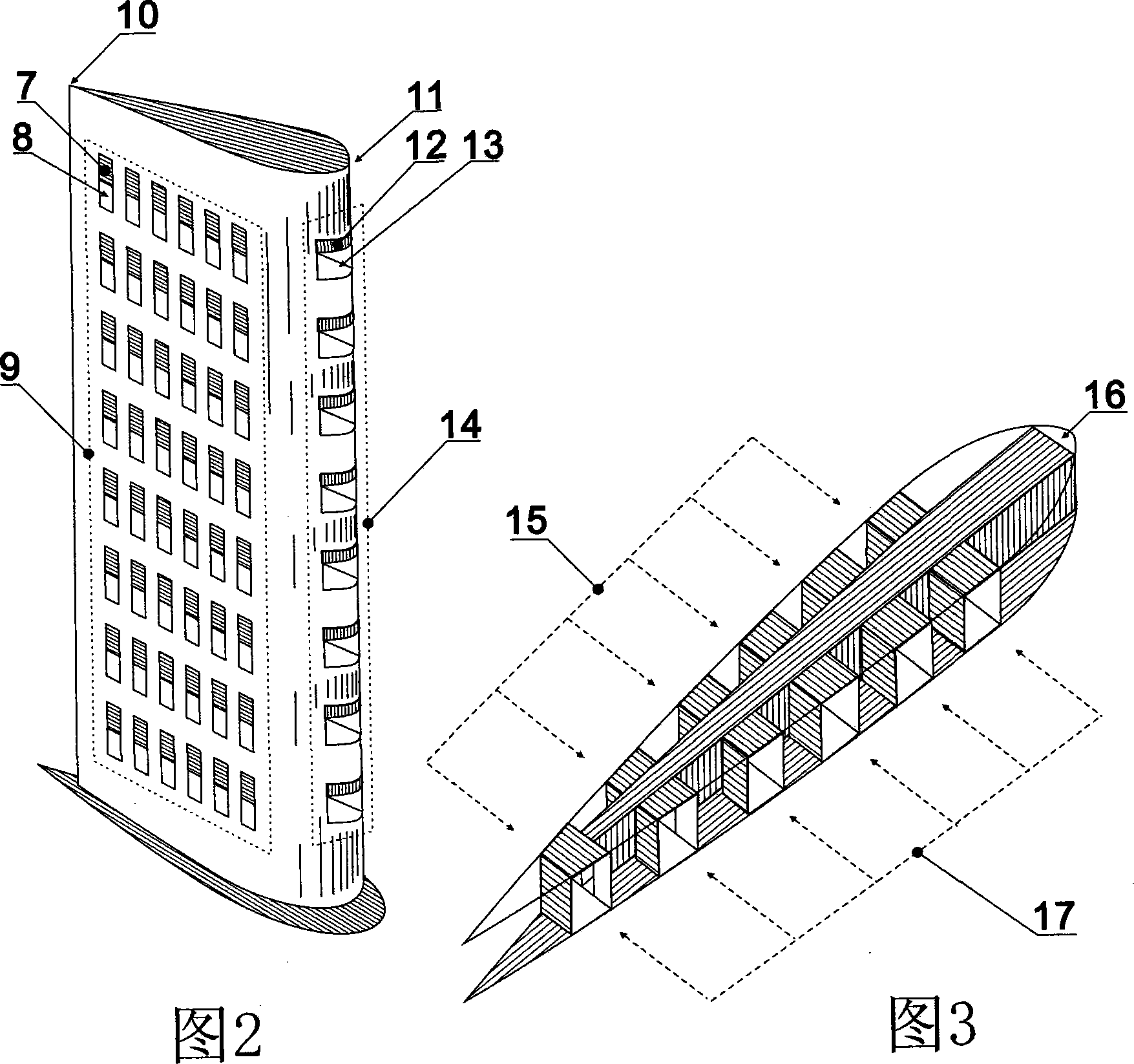

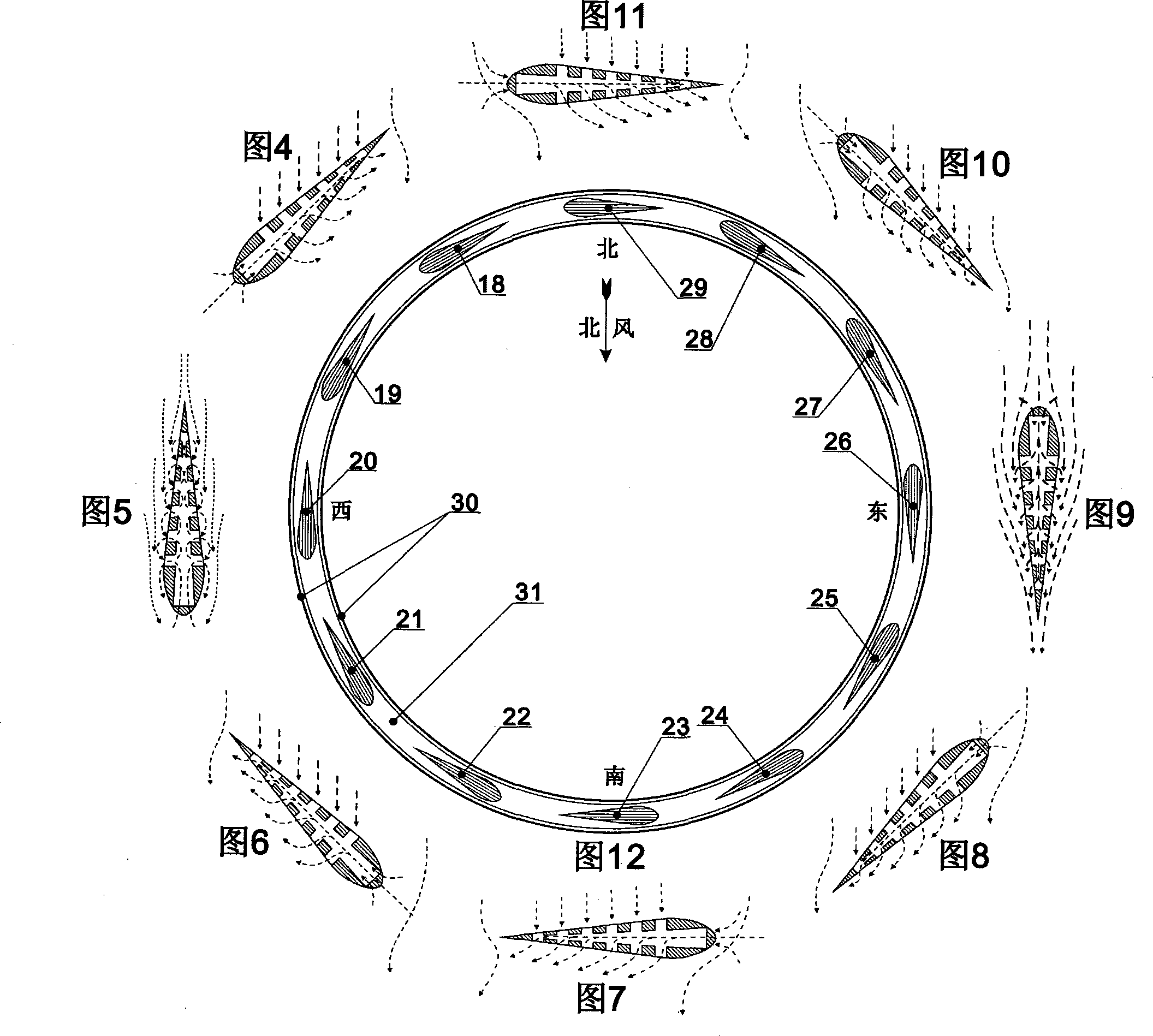

[0014] As shown in Figure 1, Fig. 2 and Fig. 3, the ramjet airfoil sail shown in Fig. 3 mainly consists of 1. jet air passage and accompanying drawings in the wingsail, and 3 six stages of ramjet units are formed, and are formed by the ramjet unit in 5. The sail surface A and 6. The two surfaces of the sail surface B are arranged in an array to form the three-dimensional structure of the stamped jet wing-shaped sail built of reinforced concrete in Fig. 2 . 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29 Each ram jet wing sail is built with reinforced concrete and evenly distributed in the magnetic levitation reinforced concrete On the annular running platform, see shown in 50,51,52,53,54,55,56,57,58,59,60,61 and 48 among Fig. 14. Reinforced concrete annular running platform 48 is suspended on a six-dimensionally oriented closed magnetic levitation track, see 44, 45, 35, 40, and the magnetic levitation can be permanent magnetic repulsion levitation or electromagnetic repulsion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com