Process of producing plant water keeping organic fertilizer

A production process and organic fertilizer technology, which is applied in the field of plant drought-resistant water-retaining organic fertilizer production process, can solve the problems that affect the application and promotion of water-retaining agents and the actual effect, cannot adapt to large-scale mechanized application, and cannot be reasonably and evenly distributed to achieve drought resistance. The application cost of water retention, beneficial to the reproduction of beneficial microorganisms and the growth and development of plant roots, and the effect of improving the efficacy of water retaining agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

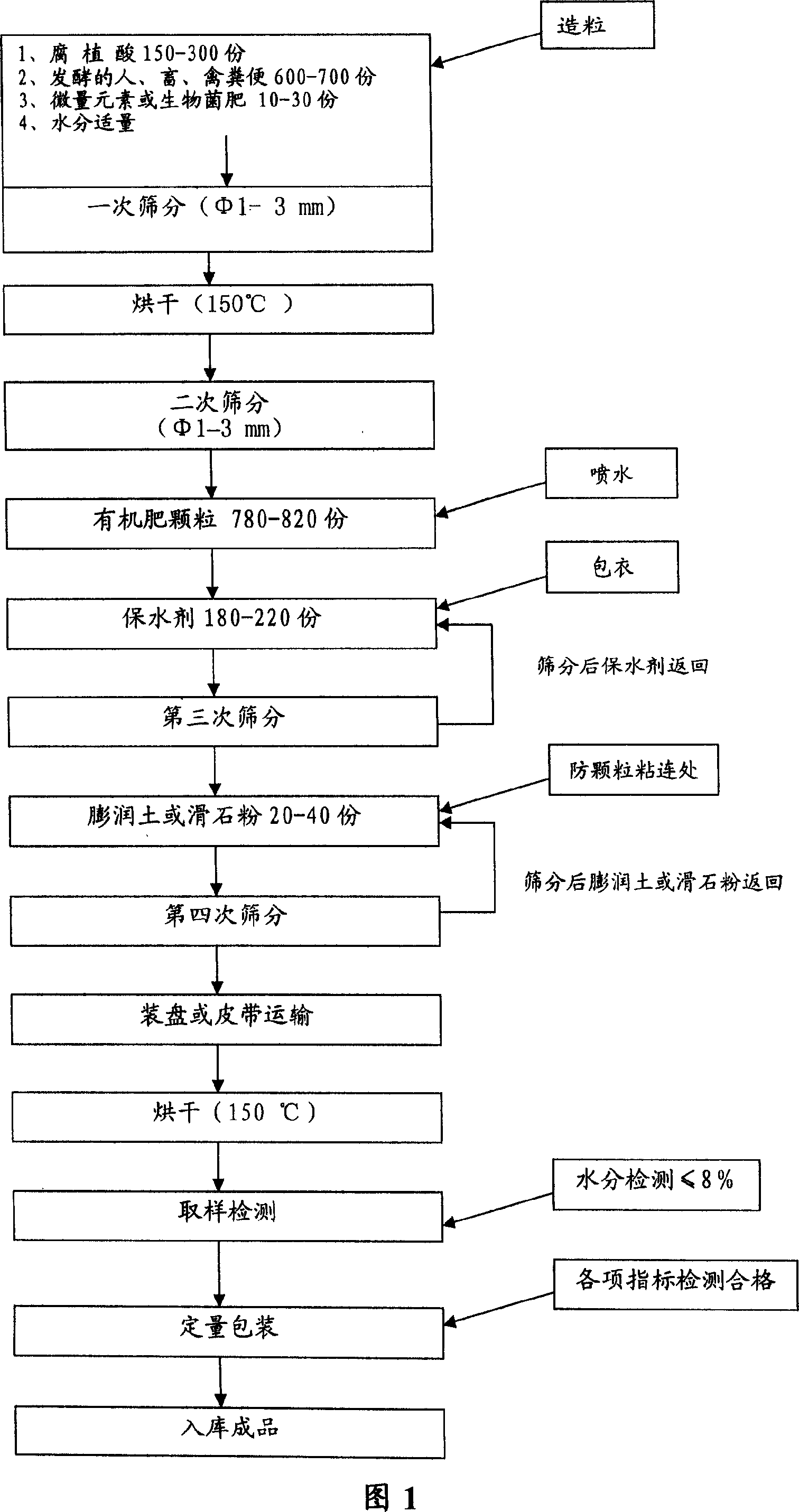

Image

Examples

Embodiment 1

[0013] First take by weighing 275 parts of humic acid (parts by weight), trace elements (copper, zinc, iron, manganese, boron, molybdenum, etc.) Parts (parts by weight); 700 parts (parts by weight) of high-quality fermented human, livestock, and poultry manure; by spraying appropriate moisture in a garden pan or drum granulator, granulation and sieving to achieve particle φ1-3mm organic fertilizer Standard granules are put into an oven (or drying room) at 150°C, taken out when the moisture content is ≤ 8% during drying, and sieved for a second time to obtain particles smaller than φ1mm. After cooling down to room temperature, weigh the organic fertilizer φ1- Put 790 parts (parts by weight) of 3mm particles into the drum granulator, spray water on the surface of the organic fertilizer particles while rolling, so that the surface of the particles is evenly moistened as a standard, and then send it into the organic fertilizer with a water-retaining agent fineness ≥ 0.18mm 210 par...

Embodiment 2

[0015] First weigh 150 parts (parts by weight) of humic acid, trace elements (copper, zinc, iron, manganese, boron, molybdenum, etc.) Parts (parts by weight); 600 parts (parts by weight) of high-quality fermented human, livestock, and poultry manure; by spraying appropriate moisture in a garden pan or a drum granulator, granulation and sieving to achieve particle φ1-3mm organic fertilizer Standard granules are put into an oven (or drying room) at 150°C, taken out when the moisture content is ≤ 8% during drying, and sieved for a second time to obtain particles smaller than φ1mm. After cooling down to room temperature, weigh the organic fertilizer φ1- Put 780 parts (parts by weight) of 3mm particles into the drum granulator, spray water on the surface of the organic fertilizer particles while rolling, so that the surface of the particles is evenly moistened as a standard, and then send it into the organic fertilizer with a water-retaining agent fineness ≥ 0.18mm 180 parts (parts...

Embodiment 3

[0017] First take by weighing 300 parts of humic acid (parts by weight), trace elements (copper, zinc, iron, manganese, boron, molybdenum, etc.) Parts (parts by weight); 700 parts (parts by weight) of high-quality fermented human, livestock, and poultry manure; by spraying appropriate moisture in a garden pan or drum granulator, granulation and sieving to achieve particle φ1-3mm organic fertilizer Standard granules are put into an oven (or drying room) at 150°C, taken out when the moisture content is ≤ 8% during drying, and sieved for a second time to obtain particles smaller than φ1mm. After cooling down to room temperature, weigh the organic fertilizer φ1- Put 820 parts (parts by weight) of 3mm particles into the drum granulator, spray water on the surface of the organic fertilizer particles while rolling, so that the surface of the particles is evenly moistened as a standard, and then send it into the organic fertilizer with a water-retaining agent fineness ≥ 0.18mm 220 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com