Method for producing high reinforced carbon white by aminating fluorosilicic acid

A technology of ammonia fluorosilicate and white carbon black, which is applied in the field of chemical product preparation, can solve the problems of limited rubber reinforcement effect, narrow use of sodium fluorosilicate, restriction of enthusiasm, etc., and achieves obvious economic and environmental benefits, operation The effect of easy control of conditions and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

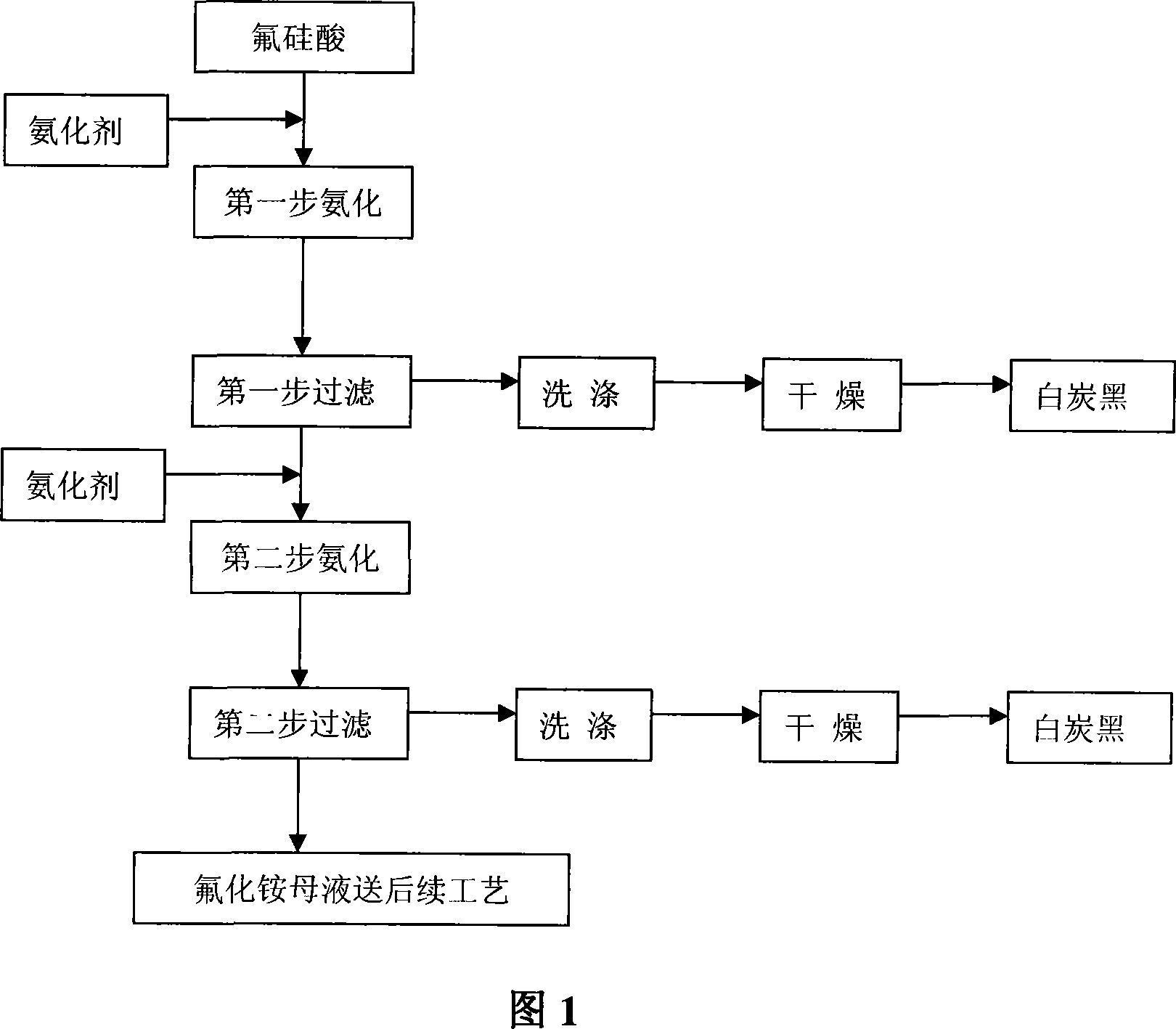

Method used

Image

Examples

Embodiment 1

[0026] Add 440.5g of 8% fluosilicic acid solution to the stirred reactor at a temperature of 20-25°C, first add 83.1g of 16% ammonia water to the fluosilicic acid solution, and age for 20 ~40 minutes, and then continue to add 46.0g of ammonia water with a concentration of 16% to the solution. After the dropwise addition, the temperature is 30~40°C, the pH is 6.5~7.4, and it is aged for 20~40 minutes, and the first step of filtration is performed. , the filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 185m 2 / g; The filtrate obtained from the first step of filtration is ammoniated again at a temperature of 20-25°C, 54.7g of ammonia water with a concentration of 16% is added to it, and it is aged for 20-40 minutes, and then 35.0g is added to it , Ammonia water with a concentration of 16%, after the dropwise addition, the temperature is 25-35°C, pH>8.0, aging for 20-40 minutes, and the second step of filtration is carried ou...

Embodiment 2

[0028] Add 355.4g of 10% fluosilicic acid solution to the stirred reactor at a temperature of 20-25°C, first add 103.3g of 20% ammonia water to the fluosilicic acid solution, after the dropwise addition , the temperature is 35-40°C, the pH is 6.8-7.3, and it is aged for 20-40 minutes, and the first step of filtration is carried out. The filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 160m 2 / g; Ammonify the filtrate obtained in the first step of filtration again at a temperature of 20-25°C, add 71.8g of ammonia water with a concentration of 20% to it, after the addition is completed, the temperature is 30-35°C, and the pH>8.0 , and aged for 20 to 40 minutes, and then filtered in the second step. The filter cake was washed and dried to obtain a white carbon black product with a specific surface area of 204m 2 / g.

Embodiment 3

[0030] Add 293.7g of 12% fluosilicic acid solution to the stirred reactor at a temperature of 27-32°C, first add 109.4g of 16% ammonia water to the fluosilicic acid solution, after the dropwise addition , the temperature is 45-50°C, the pH is 6.5-7.2, and it is aged for 30 minutes, and then the first step is filtered, and the filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 255m 2 / g; the filtrate obtained from the first step of filtration is ammoniated again at a temperature of 27-32°C, and 109.4g of ammonia water with a concentration of 16% is added thereto. After the addition is completed, the temperature is 35-40°C and the pH>8.0 , and aged for 30 minutes, and carried out the second step of filtration. The filter cake was washed and dried to obtain a white carbon black product with a specific surface area of 209m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com