Organic silicon resin composite

A resin composition, silicone technology, applied in the direction of coating, etc., can solve the problems of decreased transparency, poor mechanical strength of silicone coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

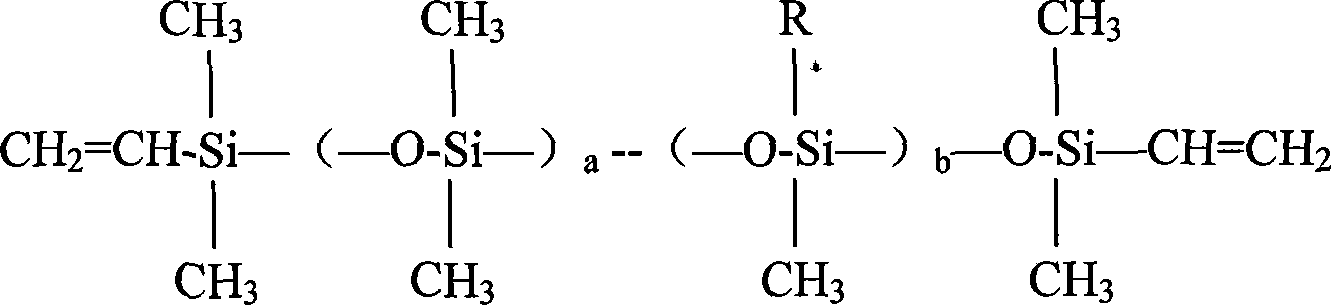

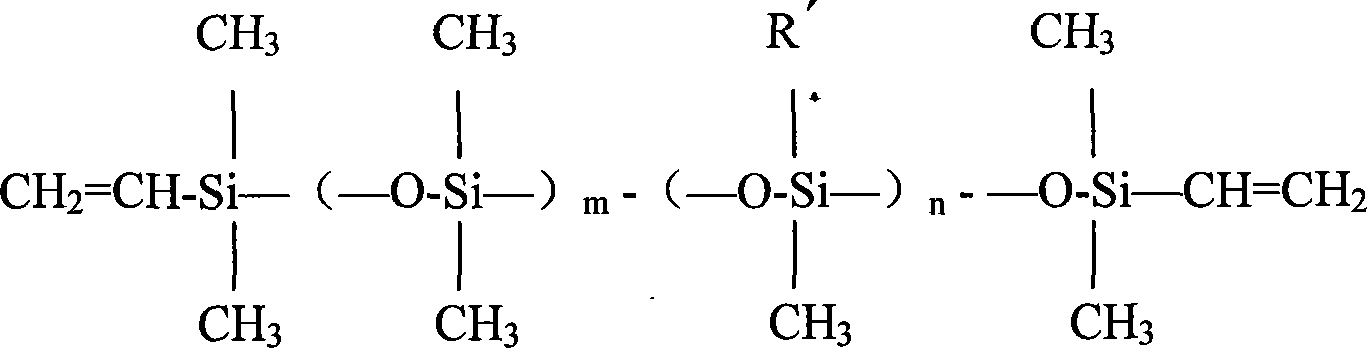

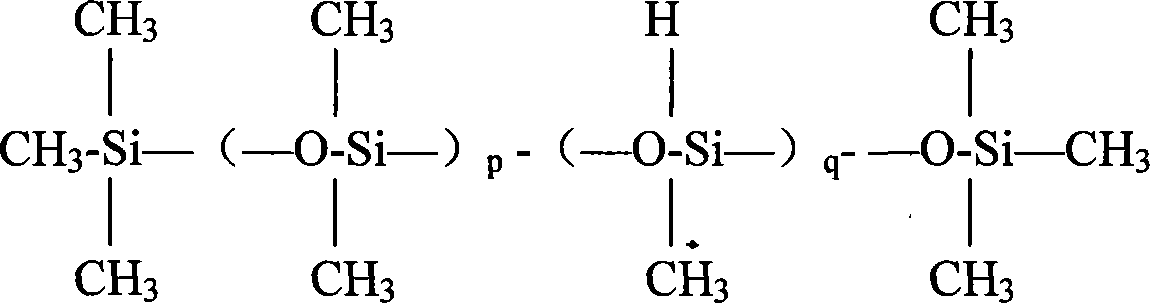

Method used

Image

Examples

example 1

[0027] Take a clean 500ml steel cup, add 100g of methyl vinyl silicone rubber (raw rubber) with a weight average molecular weight of 360,000, 50g of methyl vinyl polysiloxane with a weight average molecular weight of 35,000, and a viscosity of 800mpa S (25°C) methyl vinyl silicone resin 120g, viscosity 100mpa S (25°C) methyl hydrogen polysiloxane 10g, methyl pentynol 1.5g, stir well, add platinum catalyst (4000ppm , calculated as Pt) 1.5g, stir again evenly, remove all the air bubbles under vacuum, pour into the dispensing bottle, use the dispensing machine to put the above mixture on the text and pattern surface of the button, and then vulcanize at 150°C for 15 minutes, put The clicked button is cooled to be tested.

example 2

[0029] Take a clean 500ml steel cup, add 100g of methyl vinyl silicone rubber (raw rubber) with a weight average molecular weight of 360,000, 50g of methyl vinyl polysiloxane with a weight average molecular weight of 50,000, and a viscosity of 1200mpa S (25°C) methyl vinyl silicone resin 120g, viscosity 60mpa S (25°C) methyl hydrogen polysiloxane 10g, methyl pentynol 1.5g, stir well, then add platinum catalyst (2500ppm , calculated as Pt) 1.5g, stir again evenly, remove all the air bubbles under vacuum, pour into the dispensing bottle, use the dispensing machine to put the above mixture on the text and pattern surface of the button, and then vulcanize at 150°C for 15 minutes, put The clicked button is cooled to be tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com