Preparation and using method of plant bionic high efficient adsorbent for removing difficult degradation organic pollutant

A technology for organic pollutants and plant biomimetic, which is applied in the field of plant biomimetic high-efficiency adsorbent preparation, and can solve the problems of high use cost, easy saturation, and small adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

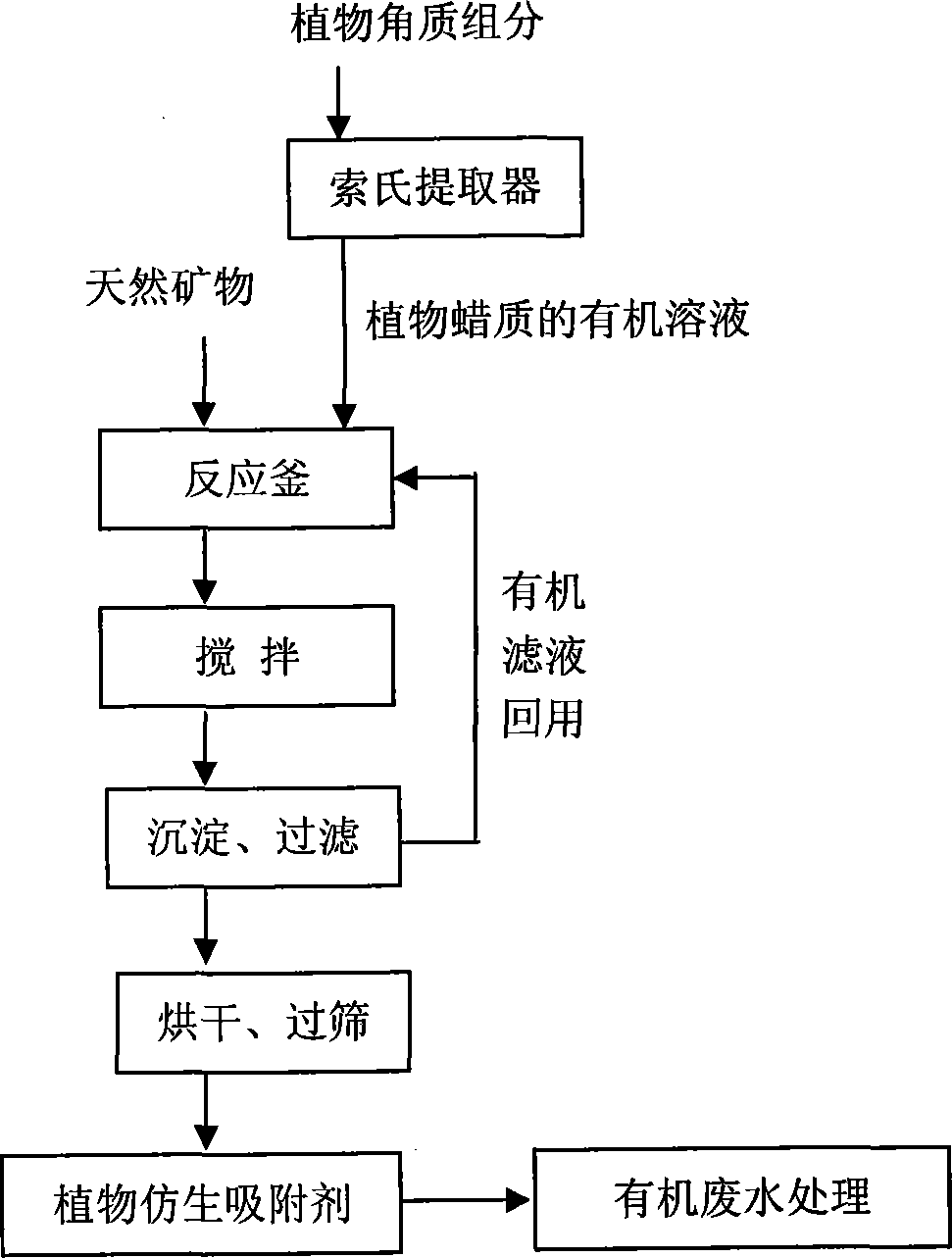

[0017] 1) Utilize the discarded plant epidermis, remove the pulp therein, obtain the plant epidermis, and obtain a natural waxy extract by the Soxhlet extraction method;

[0018] 2) mixing the waxy extract with natural clay minerals, the mass volume ratio of natural clay minerals and waxy extracts is 1:3, shaking at room temperature for 1 hour, and filtering;

[0019] 3) The filter cake was air-dried at room temperature, dried at 80° C. for 1 hour, ground, and sieved to 40 mesh to obtain a plant bionic high-efficiency adsorbent; the filtrate was recovered and reused.

Embodiment 2

[0021] 1) Utilize the discarded plant epidermis, remove the pulp therein, obtain the plant epidermis, and obtain a natural waxy extract by the Soxhlet extraction method;

[0022] 2) Mix the waxy extract with natural clay minerals, the mass volume ratio of natural clay minerals and waxy extract is 1:80, shake at room temperature for 6 hours, and filter;

[0023] 3) The filter cake was air-dried at room temperature, dried at 90° C. for 2 hours, ground, and sieved to 200 mesh to obtain a high-efficiency plant biomimetic adsorbent; the filtrate was recovered and reused.

Embodiment 3

[0025] Fresh apple peels were manually peeled, and after the peels were boiled in water for 1 h, as much pulp as possible was manually removed. It is then washed with distilled water to remove any remaining pulp and get a good amount of skin. The epidermis was extracted with a Soxhlet extractor at 70° C. for 6 h with a 1:1 organic solvent of chloroform and methanol to obtain a waxy component. After evaporation by rotary evaporator, it was allowed to dry naturally. Add 0-1.5g plant cuticle waxy sample and 30mL methanol to a 40mL sample bottle in sequence, and add a certain amount of calcium-based montmorillonite at the same time, shake it by hand to mix evenly, and shake it in a constant temperature oscillator for 6 hours at 25 °C±0.5°C. Blot up the supernatant as much as possible, place the sample in a fume hood to dry at room temperature, dry at 80-90°C for 2 hours, and grind through a 100-mesh sieve for later use. A high-efficiency plant biomimetic adsorbent is obtained, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com